The warehouse floor is undergoing a silent revolution - one where Material Handling Robots are outperforming human workers in speed, precision, and endurance while costing less than traditional conveyor systems. These intelligent machines combine cutting-edge AI with industrial-grade mechanics to handle everything from delicate pharmaceuticals to heavy automotive parts with superhuman consistency. This article reveals why 78% of Fortune 500 manufacturers are now deploying these robotic workhorses and how they're solving three critical pain points: labor shortages, operational costs, and supply chain volatility.

The Material Handling Robots Revolution: Beyond Basic Automation

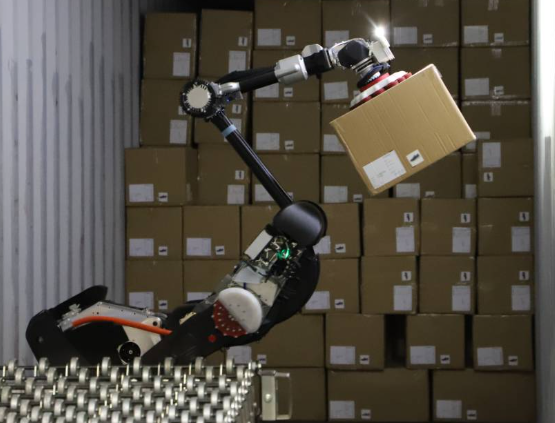

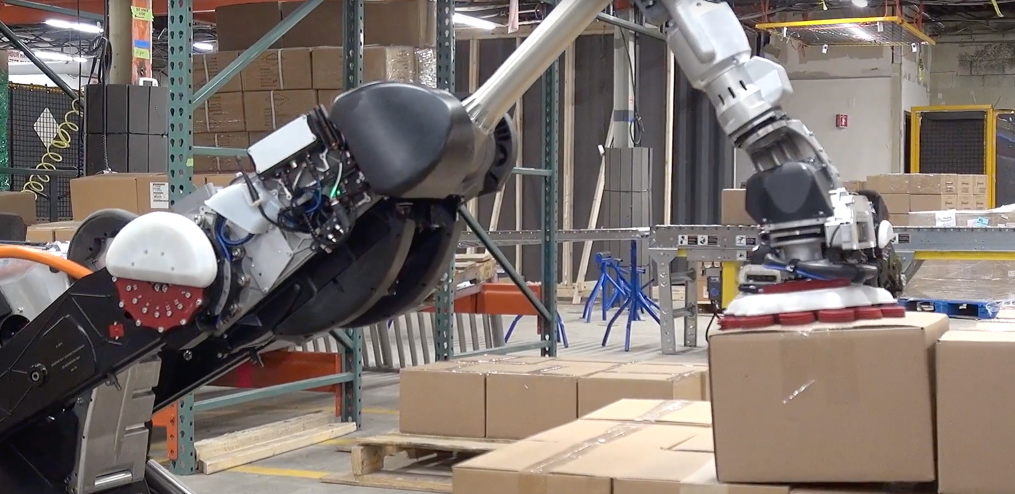

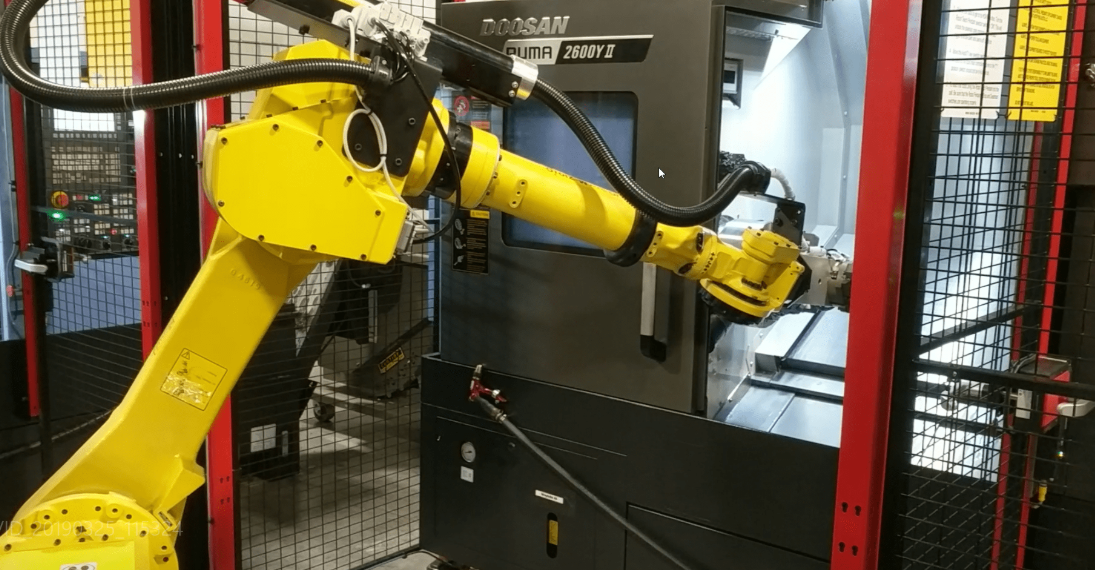

Unlike their single-purpose ancestors, modern Material Handling Robots are cognitive systems that adapt to dynamic environments. They leverage machine vision to identify irregularly shaped objects, reinforcement learning to optimize path planning in real-time, and predictive analytics to anticipate workflow bottlenecks. The latest models from companies like Boston Dynamics and Fanuc can collaboratively work alongside humans without safety cages, thanks to advanced force-limiting technology and 360° obstacle detection.

Traditional Systems

Fixed conveyor routes requiring infrastructure changes

No adaptability to product variations

High energy consumption (5-10kW continuous)

Limited data collection capabilities

Modern Material Handling Robots

Dynamic navigation with SLAM technology

AI-powered object recognition handles SKU variations

Energy-efficient (0.5-2kW with regenerative braking)

Real-time performance analytics dashboard

How Material Handling Robots Are Solving Industry Pain Points

The adoption curve for Material Handling Robots is accelerating because they address three existential threats facing manufacturers and logistics providers:

1. The Labor Crisis Solution

With warehouse turnover rates exceeding 40% annually, robots provide consistent performance without recruitment headaches. Collaborative robots (cobots) like Omron's LD Series can be trained by floor staff in under 30 minutes using intuitive touchscreen interfaces, eliminating the need for specialized programmers.

2. Space Optimization Genius

Mobile robot systems utilize vertical space and dynamic storage that traditional conveyors can't match. For example, Geek+'s robotic shuttle systems achieve 400% higher storage density by automatically adjusting shelf configurations based on real-time demand patterns.

3. The Cost Reduction Powerhouse

While initial investment seems steep, Material Handling Robots typically achieve ROI within 14-18 months. Key savings come from 60-80% reduced product damage, 24/7 operation without overtime pay, and predictive maintenance that prevents costly downtime. For more insights on cost benefits, see our analysis of Material Handling Robots as a secret weapon against soaring costs.

Implementation Roadmap: 5 Steps to Robotic Success

Process Mapping - Conduct time-motion studies to identify repetitive material transfer tasks that account for 15%+ of labor hours. These are prime robotic takeover candidates.

Payload Profiling - Document weight ranges, dimensions, and surface characteristics of handled items. This determines whether you need vacuum grippers, magnetic end-effectors, or specialized manipulators.

Infrastructure Audit - Assess floor surfaces, aisle widths, and WiFi coverage. Most AMRs require smooth floors with ≤3° inclines and consistent 5GHz network access.

Phased Deployment - Start with a pilot area handling non-critical materials. Successful implementations scale from single-robot cells to fleets of 50+ coordinated units.

Continuous Optimization - Use the robot's operational data to refine paths, adjust acceleration profiles, and rebalance workflows quarterly.

Future Trends: Where Material Handling Robots Are Heading

The next generation of Material Handling Robots will feature:

Swarm Intelligence - Fleets that self-organize like ant colonies to handle peak demands

Self-Charging Ecosystems - Wireless charging pads at idle points for 100% uptime

Digital Twin Integration - Virtual replicas that simulate layout changes before implementation

Blockchain Tracking - Immutable records of material provenance throughout handling

For a deeper dive into these advancements, explore our article on how handling robots are revolutionizing AI and automation.

FAQs About Material Handling Robots

1. How do Material Handling Robots handle irregularly shaped items?

Advanced models use 3D vision systems with machine learning that can recognize and adapt to thousands of SKUs. Some employ soft robotics technology with compliant grippers that mold to object contours.

2. What safety standards govern human-robot collaboration?

ISO 15066 specifies force and pressure limits for collaborative operation. Modern robots implement multiple safety layers including torque monitoring, 3D zone control, and capacitive skin detection.

3. Can legacy warehouse management systems integrate with robotic fleets?

Yes, most solutions offer REST API connectivity to common WMS platforms like SAP EWM and Oracle WMS. Middleware options like SVT Robotics provide no-code integration for older systems.

The Bottom Line

Material Handling Robots represent more than automation - they're a strategic asset that transforms material flow from a cost center to a competitive advantage. Early adopters are seeing 3-5x productivity gains in picking operations and 99.9% inventory accuracy. As these systems become more affordable through robotics-as-a-service models, they're no longer just for Fortune 500 companies. The question isn't whether to implement robotic material handling, but how quickly your operation can transition before competitors gain an insurmountable edge.