Imagine walking into a warehouse where forklifts zoom autonomously, pallets find their destinations without human touch, and shelves restock themselves. This isn't science fiction – it's the reality powered by Material Handling Robots. As supply chain pressures mount and finding reliable labor becomes increasingly difficult, these intelligent machines are no longer a luxury; they're a strategic necessity transforming warehouses, factories, and logistics centers globally. Forget visions of humanoids; the true revolution lies in these hardworking automatons silently optimizing the movement of goods, slashing operational costs by 20-40%, and forming the vital backbone of tomorrow's AI-driven automated world. This article dives deep into how Material Handling Robots work, their immense benefits, their critical role in the AI ecosystem, and how you can successfully deploy them to future-proof your operations.

What Exactly Are Material Handling Robots?

At their core, Material Handling Robots are automated machines specifically engineered to transport, store, retrieve, pack, and sort goods within a defined operational environment. They replace or augment manual tasks involved in moving raw materials, work-in-progress, and finished goods throughout manufacturing plants, distribution centers, warehouses, and cross-docks. Unlike general-purpose robots used for welding or assembly, Material Handling Robots specialize in the logistics of physical objects. Their forms vary dramatically, ranging from autonomous mobile robots (AMRs) navigating dynamic floorspaces to articulated robotic arms delicately picking items off shelves or powerful robotic forklifts automating pallet movement.

The Silent Powerhouses: Key Roles in Modern Industry

The applications of Material Handling Robots are vast and continually expanding, targeting core areas where efficiency gains yield massive returns:

Warehousing & Distribution Efficiency Unleashed

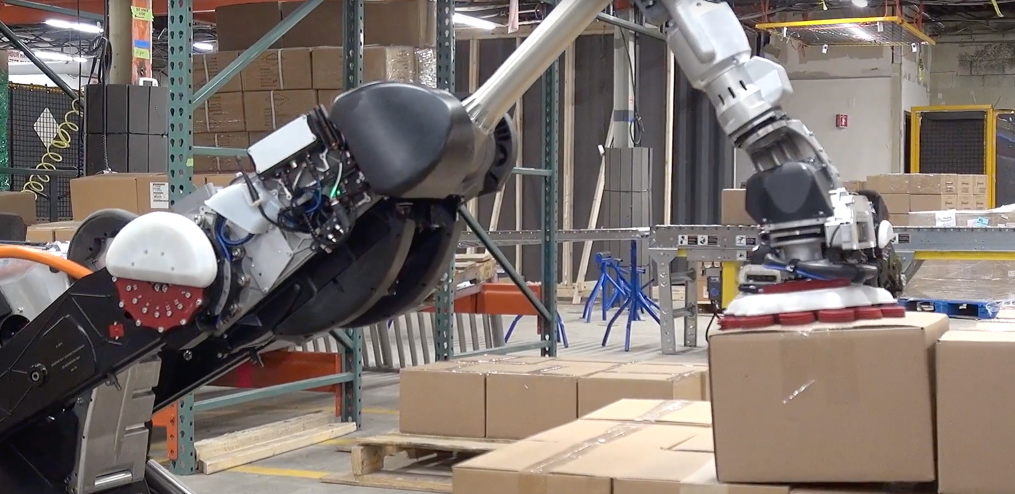

Material Handling Robots have become the engine of modern warehousing. Goods-to-Person (G2P) systems using Autonomous Mobile Robots (AMRs) bring entire shelves to pickers, drastically reducing walk times. Robotic arms paired with advanced vision systems automate picking and packing, handling items from fragile bottles to bulky boxes. Automated Storage and Retrieval Systems (AS/RS), controlled by sophisticated Warehouse Management Systems (WMS), precisely shuttle pallets or bins within high-density storage structures.

Transforming the Manufacturing Floor

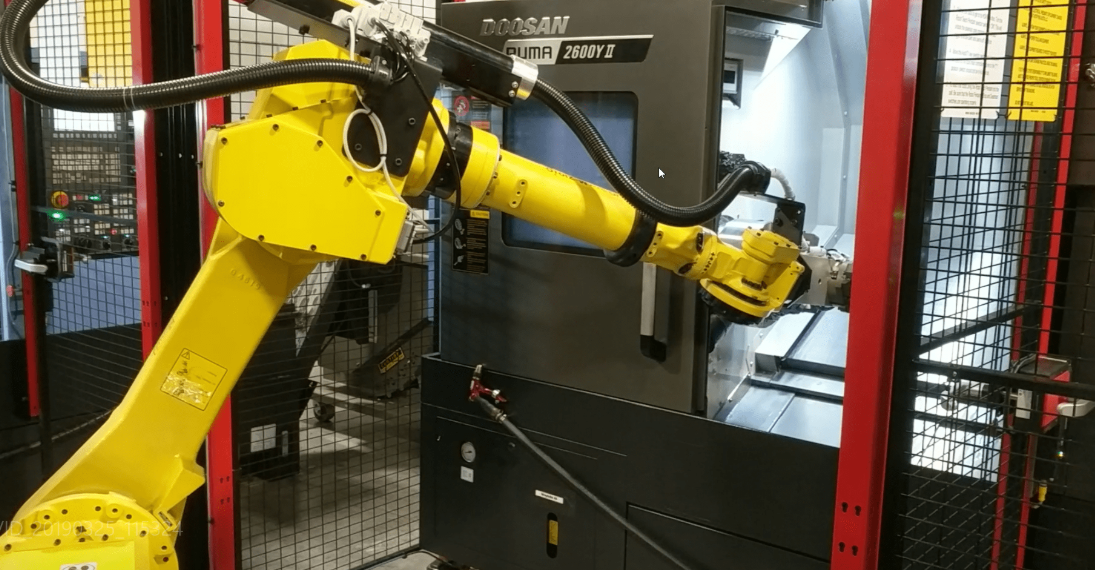

Within factories, Material Handling Robots create seamless workflows. Robotic fork trucks move raw materials from receiving docks to assembly lines. Conveyor systems, often integrated with robotic sorters or palletizers, transport components between stations. Collaborative mobile robots (cobots on AMR platforms) deliver parts directly to workers at their point of need, minimizing downtime and optimizing Just-in-Time delivery.

Revolutionizing Shipping & Receiving

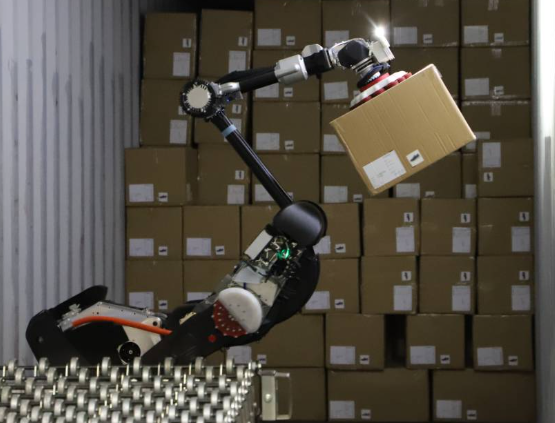

The loading dock and yard are critical bottlenecks. Robotic palletizers build stable pallet loads faster than humans. Unloading robots equipped with advanced vision and adaptive grippers tackle the complex task of depalletizing mixed-SKU trailers without damage. Some systems are even automating the trailer loading process itself, optimizing space utilization.

Why Material Handling Robots Are Now Indispensable

The shift towards automating material handling isn't just about innovation; it's driven by compelling, tangible benefits:

Slashing Sky-High Labor Costs & Shortages: Perhaps the most pressing driver. With persistent labor shortages, especially for physically demanding and repetitive warehouse roles, Material Handling Robots offer a reliable, consistent workforce 24/7/365, reducing dependency on hard-to-find labor.

Dramatic Operational Cost Reduction: While the initial investment is significant, robots rapidly pay for themselves by lowering labor overheads, reducing costly errors, and minimizing product damage. Energy-efficient designs, especially in AMRs, also contribute to savings.

Supercharged Throughput & Productivity: Robots work faster and don't take breaks. Automating movement eliminates walking, searching, and waiting times inherent in manual systems, significantly boosting overall facility throughput.

Enhanced Safety & Reduced Workplace Injuries: Material handling often involves heavy lifting, repetitive motions, and operating near heavy equipment (like forklifts). Automating these tasks drastically reduces worker musculoskeletal injuries, collisions, and forklift accidents.

Unmatched Consistency and Reduced Errors: Unlike humans, robots perform tasks identically every time. This minimizes mispicks, misplacements, and damage caused by human error, leading to higher order accuracy and customer satisfaction.

Data Generation for Continuous Improvement: Modern Material Handling Robots are data powerhouses. They constantly generate information on movement paths, task times, bottlenecks, and asset utilization, providing invaluable insights for optimizing workflows and facility design.

This data flow isn't just operational gold; it's the fuel that powers the next evolution of AI, creating a powerful feedback loop. To understand how this automation forms the foundational layer of a broader intelligent ecosystem, explore our article on the profound impact of automation: Handling Robots: The Silent Revolution Transforming AI and Automation.

AI & Material Handling Robots: The Symbiotic Relationship

The intelligence driving modern Material Handling Robots is increasingly sophisticated AI. This is far beyond simple programming:

Intelligent Navigation & Fleet Coordination (AMRs): AMRs use AI algorithms for Simultaneous Localization and Mapping (SLAM), real-time obstacle avoidance based on sensor fusion, and dynamic route optimization. Fleet management software leverages AI to coordinate dozens or hundreds of robots, optimizing task allocation and traffic flow, preventing deadlocks, and automatically rerouting around congestion.

Adaptive Picking & Grasping: Robotic arms employ AI-powered computer vision systems (often using convolutional neural networks) to identify items in chaotic bins, determine the best grasp point, and adapt grip strength in real-time for delicate or irregular objects.

Predictive Maintenance: AI analyzes sensor data (vibration, temperature, current draw) from robots to predict potential component failures before they occur, scheduling maintenance during downtime to avoid costly unplanned stoppages.

Optimized Task Scheduling & Resource Allocation: AI-driven software analyzes historical and real-time order data, inventory levels, and robot status to predict demand surges, optimize storage locations (slotting), and ensure robots are assigned to the highest-priority tasks for maximum facility efficiency. This positions Material Handling Robots as data collection agents feeding vital operational telemetry into broader AI initiatives.

Navigating the World of Material Handling Robots

Understanding the different types is crucial when considering automation:

Automated Guided Vehicles (AGVs): Follow fixed paths (wires, magnets, tape), predictable and reliable for point-to-point tasks but inflexible. Suited for structured environments.

Autonomous Mobile Robots (AMRs): Navigate freely using onboard sensors (LiDAR, cameras, IMU), lasers, and sophisticated software. Highly flexible, can navigate around obstacles and dynamically reroute. Ideal for complex, changing environments. The core of Goods-to-Person systems.

Automated Storage/Retrieval Systems (AS/RS): Include unit-load cranes, mini-load systems, shuttles, and vertical lift modules (VLMs). Maximize vertical space, provide very high throughput and accuracy for inventory management.

Robotic Arms for Material Handling: Articulated robots mounted on fixed bases or mobile platforms (AMRs/Mobile Robots). Used for depalletizing, palletizing, packing, machine tending, and bin picking.

Robotic Forklifts: Automate pallet movement, loading/unloading, reaching tasks. Vary in sophistication from guided path to fully autonomous.

Conveyor & Sortation Systems (with AI): While traditional, modern systems integrate AI vision and robotic arms for sorting complex items, reading labels in any orientation, and merging streams intelligently.

Beyond Efficiency: The Strategic Role of Material Handling Robots in Scalable Operations

The true value extends far beyond replacing a labor unit. Material Handling Robots provide a foundation for resilient, adaptable operations:

Scalability: Adding robots is often faster and easier than hiring, training, and integrating large numbers of new staff, especially during peak seasons.

Flexibility: AMR fleets, in particular, can be reconfigured or re-tasked quickly to adapt to new workflows, product lines, or facility layouts without major infrastructure changes.

Enhanced Resilience: Automating key tasks buffers operations against labor fluctuations (absences, turnover, shortages) and unexpected spikes in demand.

Optimizing Real Estate: AS/RS systems drastically increase storage density, allowing more inventory in the same space or reducing overall facility footprint requirements. AMRs operating in narrower aisles achieve similar outcomes.

Data-Driven Decision Making: The operational data captured by robots provides unparalleled transparency into workflow efficiency and bottlenecks, enabling continuous improvement initiatives.

Getting Started with Material Handling Robots: A Realistic Roadmap

Deploying automation successfully requires careful planning:

Step 1: Define Your Goals & Map Processes Rigorously

Start with the "why." Pinpoint the specific pain points (throughput bottlenecks, high labor costs, error rates, safety issues, specific labor-intensive tasks). Quantify current performance metrics. Conduct a thorough Value Stream Mapping exercise to visualize material and information flow, identifying non-value-added steps ripe for automation. Focus on repetitive, predictable tasks like horizontal transport or simple pallet movements first.

Step 2: Conduct an Honest Site Assessment

Evaluate your physical environment: Floor flatness, clearance heights, aisle widths, condition of flooring, charging locations, Wi-Fi coverage (critical for AMRs). Identify potential obstacles and traffic patterns involving both humans and existing machinery.

Step 3: Choose the Right Technology Partner (Not Just Hardware)

Vet suppliers thoroughly. Look beyond the robot hardware. Evaluate their fleet management software (FMS) capabilities – this is crucial. Assess the ease of integration with your existing Warehouse Management System (WMS), Enterprise Resource Planning (ERP), and other software. Demand strong local support and proven experience in solutions similar to your requirements. Consider scalability needs.

Step 4: Develop a Phased Implementation Plan

Don't try to automate everything at once. Develop a clear pilot program. Choose a well-defined, manageable task or workflow segment. Start small (e.g., automating transport between two specific points). Establish clear Key Performance Indicators (KPIs) for success (e.g., task time reduction, error reduction, labor reallocation). Document the process meticulously.

Step 5: Factor in Integration & Change Management

Understand that software integration is complex. Budget time and resources for WMS integration specialists. Crucially, invest heavily in change management. Involve employees early. Communicate transparently about the reasons for automation and how it will impact their roles (often shifting them to higher-value tasks). Provide comprehensive training on operating, supervising, and interacting safely with the new robotic systems.

Step 6: Scale Strategically Based on Data

Analyze the pilot results rigorously. Did you achieve the KPIs? What lessons were learned? Use this data-driven insight to refine your approach before expanding the deployment scope. Build upon your initial success gradually.

Frequently Asked Questions (FAQs)

Q: Aren't Material Handling Robots too expensive for smaller businesses?

A: While historically high-cost, the Material Handling Robots landscape is evolving rapidly. Increasingly modular AMR solutions and Robotics-as-a-Service (RaaS) models significantly lower the barrier to entry. RaaS allows paying a monthly subscription fee instead of large upfront costs, making automation feasible for SMBs. A thorough cost analysis, factoring in reduced labor costs, errors, and damages, often reveals a strong ROI within 1-3 years even for smaller deployments.

Q: How long does it realistically take to implement Material Handling Robots?

A: Implementation timelines vary significantly based on complexity. A pilot involving a few AMRs on a specific internal transport task might be deployed in weeks. A large-scale Goods-to-Person system integrating dozens of AMRs, pick stations, and WMS might take 6-18 months for complete integration and optimization. Phased deployment is key. Start simple and scale gradually.

Q: What happens if robots break down? Won't this halt operations?

A: Modern systems are designed for resilience. Fleet Management Software automatically reroutes tasks if a robot encounters an issue or goes offline. Facilities typically maintain redundant capacity (e.g., having more robots than strictly needed for baseline tasks) and establish preventative maintenance schedules (informed by AI predictive analytics). Critical path components often have redundancy. The goal is high availability comparable to, or exceeding, manual systems.

Q: How do AMRs safely navigate around people and other obstacles?

A: AMRs utilize sophisticated multi-layered safety systems certified to standards like ANSI/RIA R15.08. This includes a suite of sensors: laser LiDAR for constant 360° detection, 3D cameras, ultrasonic sensors, and often safety-rated bumpers. Advanced navigation AI allows smooth, predictive path planning and adaptive speed reduction based on proximity to obstacles. Zones can be defined (e.g., near packing stations) where robot speed is automatically capped.

The Future Landscape: Where Material Handling Robots Are Heading

The evolution is accelerating:

Hyper-Automation Integration: Material Handling Robots will become seamlessly intertwined with other automated systems like robotic picking/packing, automated packaging machines, and advanced sortation, creating end-to-end autonomous workflows.

AI Becoming the Central Operating System: AI won't just assist; it will fundamentally orchestrate entire material flows, making complex operational decisions in real-time, optimizing energy usage, and dynamically reconfiguring tasks globally across a facility based on live data.

Enhanced Manipulation & Dexterity: Grippers will become significantly more adaptable and sensitive, allowing robots to handle vastly wider ranges of items – from delicate produce to complex assemblies – with minimal custom tooling. Tactile sensing will advance.

Mass Adoption of RaaS: The Robotics-as-a-Service model will become dominant, particularly for AMRs and collaborative arms, further democratizing access to automation by shifting cost structures from CapEx to OpEx.

Synergy with Generative AI & Simulation: Generative AI will aid in designing highly optimized robotic workflows and facility layouts. Sophisticated simulation tools (digital twins) will become essential for validating and refining deployments before physical implementation.

Conclusion: Embrace the Silent Workhorse of Automation

While flashy humanoid robots capture headlines, it's the unassuming Material Handling Robots that are doing the heavy lifting in the trenches of global logistics and manufacturing right now. They are the indispensable, data-generating foundation enabling the efficiency, resilience, and scalability modern operations demand. From tackling crippling labor shortages and skyrocketing costs to unlocking unprecedented levels of data-driven optimization and enabling next-level AI strategies, these systems are far more than just cost-cutting tools – they are the strategic platform upon which competitive, future-proof businesses are being built. Ignoring the potential of Material Handling Robots is no longer an option; understanding and strategically deploying them is key to thriving in the automated age. Start mapping your automation journey today – the silent revolution in your warehouse or factory has already begun.