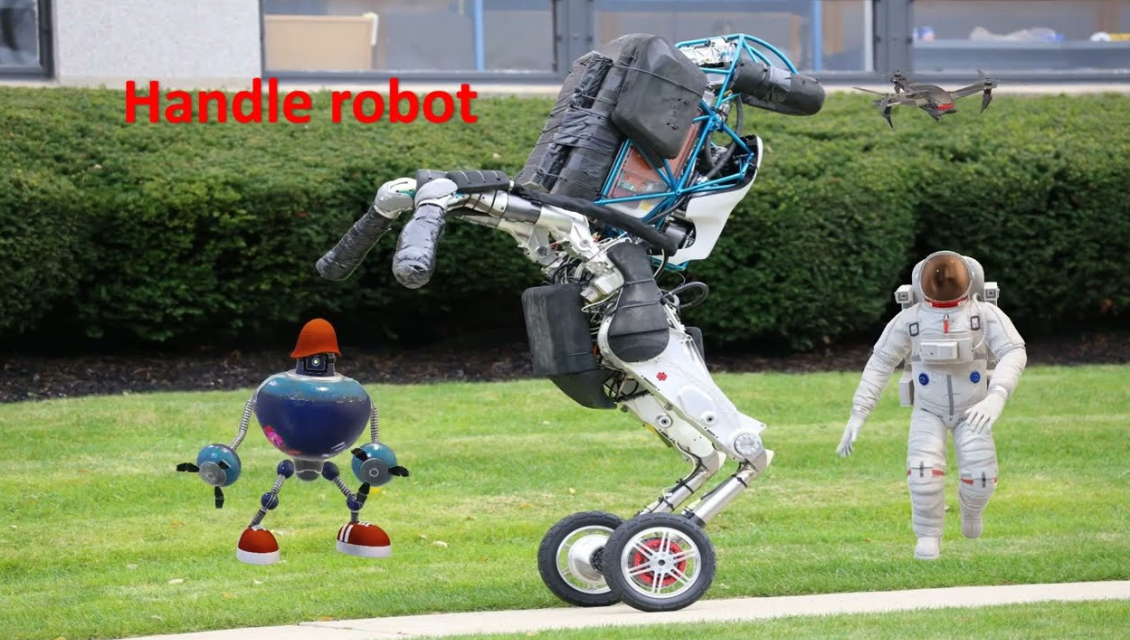

The Handle Robot Revealed: More Than Just a Warehouse Workhorse

Conceived in Boston Dynamics' labs, Handle defies robotic conventions with its hybrid locomotion system—combining wheels for speed with articulated legs for navigating obstacles. Equipped with depth-sensing cameras and machine vision algorithms, it perceives warehouse environments in 3D, distinguishing pallets from parcels at lightning speed. What truly sets Handle apart is its counterbalancing kinematic system, allowing gymnastic feats while transporting heavy loads without tipping.

Engineering Marvels Under the Hood

The magic lies in Handle's dynamic stabilization system, which continuously calculates weight distribution 200 times per second. When lifting asymmetrical loads (like unbalanced boxes), its torso pivots like a figure skater mid-spin to maintain equilibrium. This allows maneuvering in tight spaces that would stall forklifts—critical in congested warehouse aisles.

What Does The Handle Robot Do? Logistics Superpowers Unleashed

While traditional AGVs follow magnetic tapes, Handle operates autonomously using spatial intelligence—analyzing stacking patterns, calculating box dimensions, and making real-time decisions. Its core functions reshape warehouse workflows:

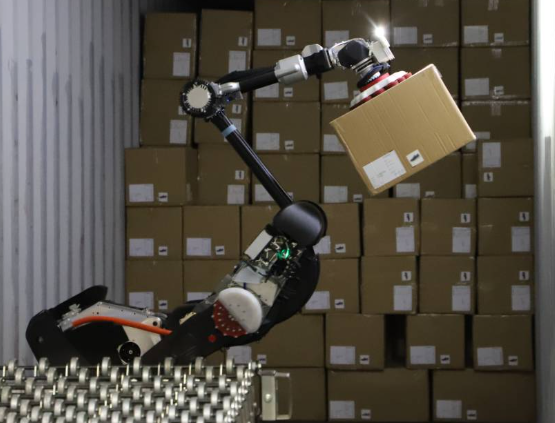

Trailer Unloading: The Impossible Made Routine

Handle's signature feat is unloading shipping containers—a task previously deemed impossible for automation due to chaotic box arrangements. Using suction grippers and articulated arms, it swiftly lifts packages off truck floors. Its curved-path navigation lets it enter trailers diagonally, maximizing space utilization while avoiding collisions. During one trial, Handle cleared a 40-foot container in 15 minutes—half the time of human crews.

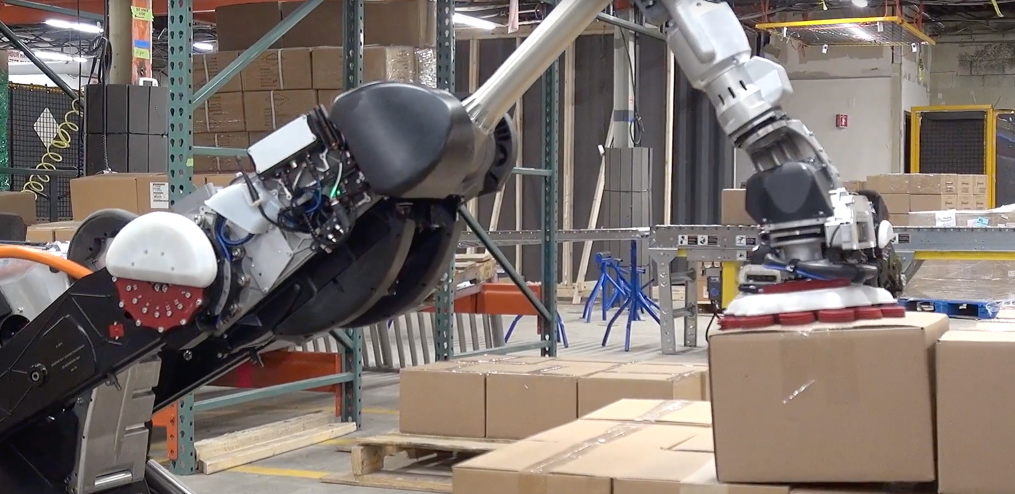

Intelligent Stacking: Where Algorithms Meet Architecture

Beyond transport, Handle builds warehouse-ready pallets. Machine learning algorithms determine optimal stacking sequences based on box dimensions and content fragility. The robot places parcels like a master Jenga player—calculating weight limits and center of gravity. In tests, stacks created by Handle endured vibration simulations equivalent to cross-country trucking.

Why Logistics Giants Are Betting on Handle

Traditional warehouses lose $200 billion annually from package damage and inefficient workflows. Handle's impact transcends speed—it eradicates three chronic pain points:

The Injury Prevention Paradox

By handling tasks with 2-3 injury risk factors (heavy lifting, repetitive motion, unstable loads), Handle reduces worker compensation claims by up to 90%. One fulfillment center reported zero lifting injuries in six months post-deployment—a first in its 30-year history.

Throughput Revolution: 3x More, 24/7

Unlike human operators requiring breaks, Handle operates continuously with 45-second battery swaps. DHL warehouses integrated the bot saw throughput spike from 200 to 700 boxes/hour per workstation. This scalability makes overnight e-commerce shipping feasible during seasonal surges.

The Space Optimization Edge

Handle's compact turning radius enables narrower aisles, increasing storage density by 22%. Its vertical reach stacks inventory up to 12 feet high without ladders—effectively adding "invisible square footage" to constrained facilities. Explore how Handle reimagines warehouse economics further in our deep dive.

Beyond the Hype: Handle's Niche in Robotic Ecosystems

Handle isn't a forklift replacement but a specialized problem-solver. Where autonomous mobile robots (AMRs) move standardized pallets, Handle thrives in chaotic environments with diverse packaging. Its key differentiation:

Fragile Item Mastery

Using force-torque sensors in its grippers, Handle adjusts lifting pressure dynamically. When moving glassware boxes, it maintains constant acceleration curves to prevent internal collisions—an impossible task for conveyor-based systems.

The Unstructured Environment Specialist

Unlike automated storage systems requiring perfect bar codes, Handle identifies packages via shape and texture analysis. During trials at FedEx hubs, it successfully handled torn/missing-label parcels by cross-referencing size data against shipment manifests. Discover how Boston Dynamics' tech stack enables these feats.

Future Horizons: Where Handle Goes Next

With Boston Dynamics refining its Pick system using machine learning, Handle's capabilities are expanding into unprecedented areas:

Cold Chain Domination

Current prototypes operate in -20°F freezers without performance loss—ideal for pharmaceutical logistics. With embedded humidity sensors, Handle can even detect compromised packaging during transport.

Multi-Robot Coordination

Fleets of Handles are now test-performing "swarm tasks." During unloading, one unit scans container contents and wirelessly coordinates peers to simultaneously handle multiple freight stacks. Early data suggests a 50% efficiency jump over solo operations.

FAQs: Your Handle Robot Questions Answered

Q: Can the Handle Robot fully replace human warehouse workers?

A: It automates only the most dangerous and repetitive tasks like heavy box lifting. Humans remain essential for quality control and complex exception handling.

Q: How does Handle Robot navigate without pre-programmed paths?

A: Real-time 3D mapping creates dynamic navigation graphs, while onboard sensors detect obstacles instantly adjusting its route.

Q: What's the energy consumption versus human operators?

A: Handle uses just 250W during operation—equivalent to 3 human bodies' metabolic energy output during the same task.

Final thoughts: Handle Robot isn't just performing logistics tasks—it's rewriting supply chain physics. By conquering "unautomatable" challenges with unprecedented grace and intelligence, this machine points toward a future where warehouses hum with symbiotic human-robot workflows. The question isn't whether to adopt such systems, but how fast companies can integrate them before competitors gain an unassailable edge.