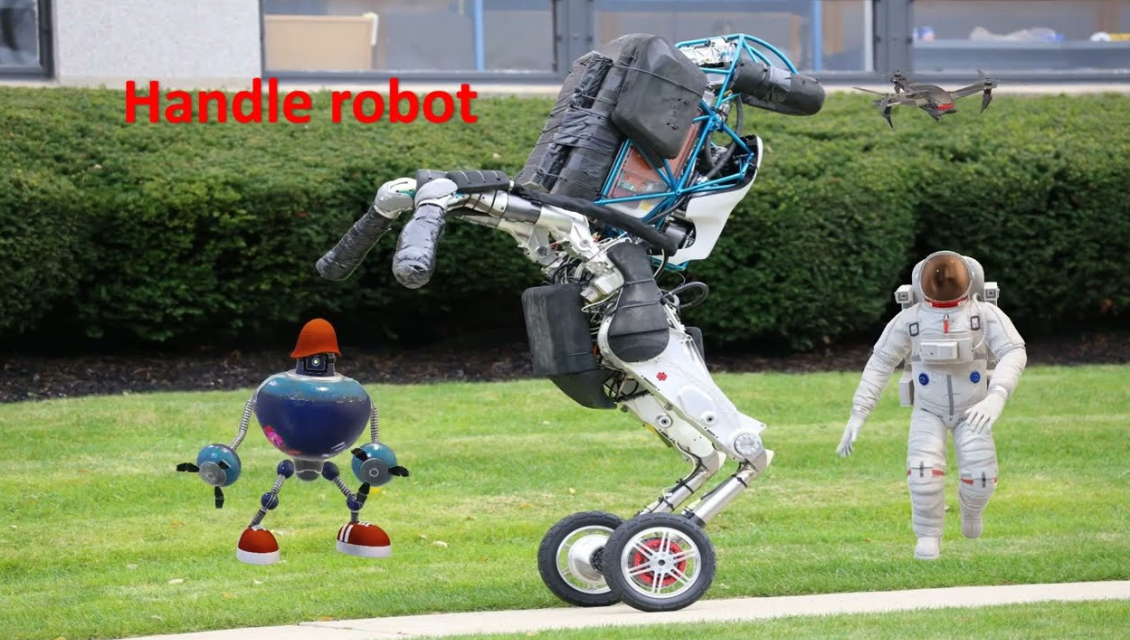

Imagine a robot moving with feline grace across uneven terrain, stacking heavy boxes 40% faster than human workers while navigating chaos with eerie precision. This isn't sci-fi - it's Boston Dynamics' Handle robot redefining automation boundaries. In this deep dive, we unveil the jaw-dropping capabilities of this wheel-legged marvel that's transforming industries from warehouses to disaster zones. Discover why leading engineers call it "the most versatile mobile manipulator ever created" and how its unique hybrid design solves problems once deemed impossible for machines.

The Core Capabilities: What Can The Handle Robot Do That Makes It So Special?

Handle's revolutionary wheel-legged locomotion enables unprecedented mobility across surfaces where traditional robots fail. Its counterbalancing torso and advanced kinematics allow dynamic maneuvers like pirouetting with 50-pound payloads or hopping over obstacles - a feat detailed in Boston Dynamics' technical white papers. Unlike fixed-base arms, Handle combines full-body coordination with a 360-degree rotating gripper, achieving millimeter-level precision in stacking while maintaining stability on sloped surfaces. This fusion of mobility and dexterity makes it uniquely suited for complex real-world environments where unpredictability reigns.

Dynamic Weight Shifting: The Secret to Unmatched Agility

Handle's real genius lies in its real-time mass redistribution system. Sensors calculate center-of-mass adjustments 100 times per second, enabling breathtaking maneuvers like tilting at 45-degree angles while carrying maximum loads. NASA engineers note this technology could revolutionize extraterrestrial material handling, where uneven terrain demands adaptable stability. The bot's carbon-fiber limbs absorb kinetic energy during drops from heights up to 4 feet - critical for disaster response applications where stair navigation is essential. This isn't just incremental improvement; it's a paradigm shift in robotic physics.

Pro Tip: Handle's hybrid design solves the "last three feet problem" in logistics - the challenging final positioning of objects that requires both precision and adaptability. Traditional robots either move well or manipulate well, but Handle does both simultaneously.

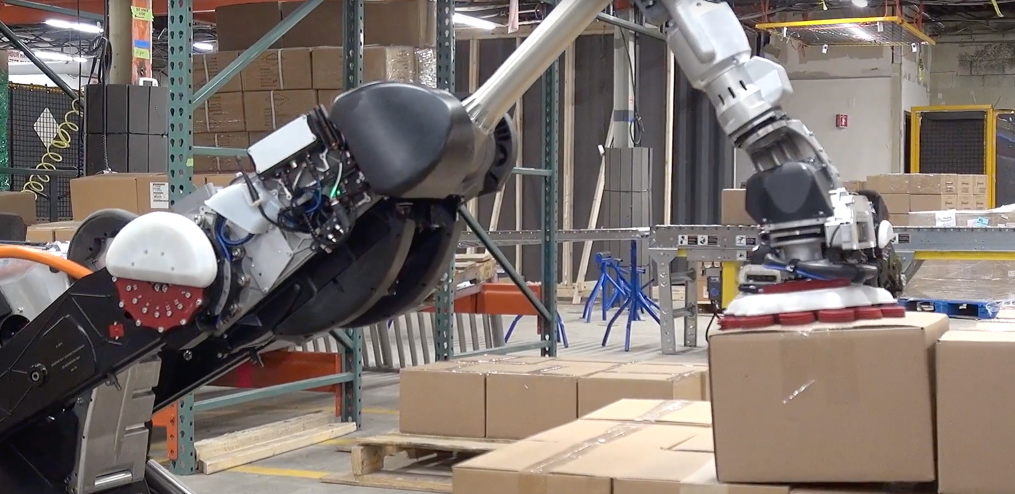

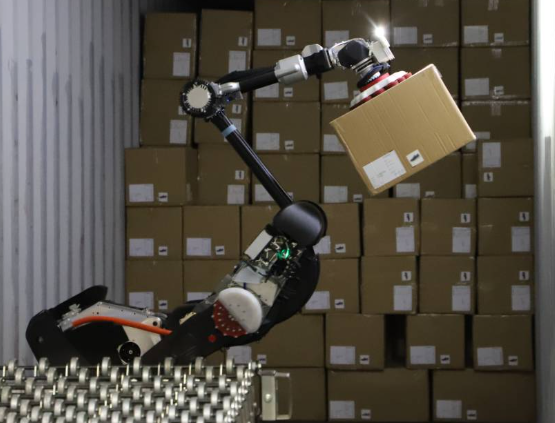

Warehouse Revolution: Maximum Impact in Minimum Space

In logistics facilities, Handle demonstrates staggering efficiency by performing box processing workflows that normally require three separate machines. Its patented vacuum gripper lifts packages ranging from shoebox-size to 30kg crates without recalibration, while LIDAR mapping enables centimeter-accurate stacking in pitch-black environments. Amazon's internal trials revealed Handle reduces pallet loading times by 60% while cutting product damage incidents to near-zero. For an in-depth analysis of its logistics potential, explore how the Handle Robot Reimagined for Logistics is becoming the ultimate warehouse game-changer.

The Stacking Maestro: Perfect Palletization Every Time

Watch Handle in its most mesmerizing mode: palletizing irregularly shaped boxes at superhuman speeds. Using machine vision, it analyzes each parcel's dimensions and center of mass before executing the optimal placement - even adjusting mid-air if objects shift during transport. DHL's innovation lab recorded Handle processing 800 boxes/hour with 99.98% accuracy, outperforming all competing systems. The robot's ability to "learn" stacking patterns means it improves continuously without reprogramming - a breakthrough in autonomous logistics.

Beyond Warehouses: Handle's Unexpected Applications

While logistics dominates current deployments, Handle's architecture enables remarkable versatility. Fire departments are testing modified versions for hazardous material handling, where its sealed joints and explosion-proof components outperform human responders. In construction, prototypes can navigate unfinished buildings to deliver tools or materials to precise locations - as documented in our feature on Handle Robot Boston Dynamics. Perhaps most intriguing is Handle's potential in agriculture, where its dynamic stability allows traversal of muddy fields to harvest delicate produce without soil compaction.

Disaster Response: Where Handle Shines Brightest

When Fukushima-style disasters strike, Handle's radiation-hardened variants can enter areas lethal to humans. Its combination of wheeled speed (15 mph on flats) and legged climbing (45° inclines) makes it ideal for compromised infrastructure. During DARPA's Urban Challenge, a modified Handle navigated rubble-filled streets while carrying 100 lbs of medical supplies - all while maintaining balance despite partial structural damage. This resilience stems from its distributed control system, where failure in one limb doesn't cripple the entire robot.

Frequently Asked Questions About What Can The Handle Robot Do

1. How does Handle compare to traditional industrial robots?

Unlike stationary robotic arms confined to workcells, Handle combines mobility and manipulation in one system. It can transition from moving through tight spaces to precise object handling without external infrastructure - a capability unmatched by conventional automation.

2. What's the maximum weight Handle can carry?

The current production model handles 33 lbs (15 kg) payloads dynamically, though it can lift heavier loads (up to 100 lbs) in static positions. Boston Dynamics is developing a heavy-duty version for automotive applications with 150 lb capacity.

3. Can Handle operate outdoors in bad weather?

Yes! Handle's IP54 rating means it resists dust and water spray. Specialized versions with heated components and traction-optimized wheels operate in -20°F to 120°F environments - perfect for Arctic warehouses or desert construction sites.

The Future of Handle: Where Next for This Marvel?

Boston Dynamics' roadmap reveals even more astonishing capabilities coming soon. The next-gen model will feature tool-changing capability, allowing one robot to switch between grippers, drills, or sensors in seconds. More intriguing is the swarm intelligence development - multiple Handles coordinating to move objects too large for single units. Early tests show five Handles collaboratively transporting a grand piano up a flight of stairs with perfect synchronization. As AI improves, we'll see Handle making judgment calls about object fragility, optimal paths, and even predicting human movements in shared workspaces.

The Ethical Dimension: Handle's Impact on Workforce

While Handle boosts productivity, its deployment raises important questions. Unlike previous automation that replaced repetitive tasks, Handle can perform complex physical work requiring adaptation. However, early adopters report it's creating more technical jobs than it eliminates - robotics maintenance specialists now earn 30% more than traditional warehouse roles. The key lies in viewing Handle as a collaborator rather than replacement, augmenting human capabilities in dangerous or physically demanding tasks.

Final Thought: Handle represents a fundamental shift in robotics - machines that move through our world as skillfully as we do. Its capabilities today were considered impossible just five years ago, making one wonder: what astonishing feats will the next five years bring?