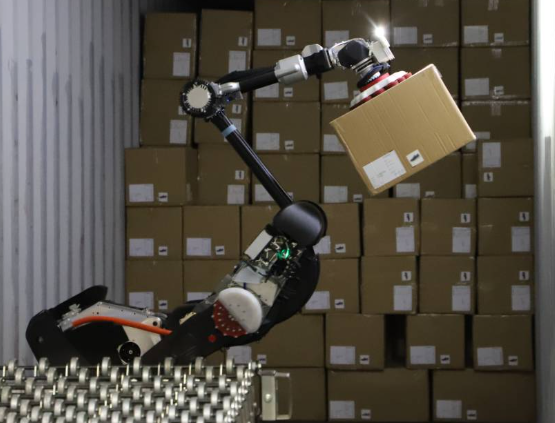

Picture a robot that glides across floors with balletic grace, stacks boxes like an Olympian weightlifter, and redefines the laws of physics—while your average factory bot struggles to cross a doorway. This isn't sci-fi; it's the Boston Dynamics Handle Robot, a revolutionary leap in automation technology. In this deep dive, we'll dissect how Handle's radical wheel-leg hybrid design and explosive athleticism create differences so profound they're reshaping global logistics and robotics forever.

The Genesis of Greatness: Where Boston Dynamics Handle Robot Fits in Robotics Evolution

Unlike incremental updates to existing platforms, Handle emerged from Boston Dynamics' moonshot philosophy of reimagining fundamental mechanics. Where traditional industrial robots evolved from stationary arms, Handle represents a disruptive paradigm shift—combining decades of MIT spin-off research with animal-inspired agility. Its 2017 debut stunned engineers by solving mobility challenges that plagued peers for generations.

Hybrid Design Philosophy: Breaking the Wheel-vs-Leg Dichotomy

The Boston Dynamics Handle Robot scoffs at compromises. Where competitors choose wheels for speed or legs for terrain, Handle merges both via inverse kinematics. Its retractable legs absorb shocks during 4-foot jumps, while carbon-fiber wheels enable 9 mph sprinting—a dual capability no pallet-jacking AMR or bipedal bot can match. This lets Handle conquer environments from ramps to rubble that immobilize single-mode robots.

Meanwhile, standard warehouse robots like Locus Vector require flat floors, sacrificing versatility for predictability. Even advanced humanoids like Honda's Asimo lack Handle's payload-to-weight ratio of 100+ pounds, forcing them into ceremonial roles. Handle's design breakthrough isn't just better engineering; it's a physics-defying rework of robotic DNA.

Head-to-Head: Boston Dynamics Handle Robot vs. Competitors Category by Category

Warehouse Warriors: Handle vs. Automated Guided Vehicles (AGVs)

While AGVs follow magnetic tapes or QR codes, Handle uses SLAM (Simultaneous Localization and Mapping) for real-time spatial intelligence. AGVs like Kivnon's K03 transport bins on fixed routes, but Boston Dynamics Handle Robot dynamically reroutes around obstacles while stacking irregular loads—crucial for e-commerce chaos.

Handle's arm elevates it further. AGVs require separate lift attachments, adding complexity; Handle's integrated 3D vision arm autonomously grasps boxes mid-stride. This single-system efficiency slashes operating costs, validating Handle Robot Reimagined for Logistics: The Warehouse Game-Changer You Can't Ignore.

Dynamic Challengers: Handle vs. Bipedal/Humanoid Robots

Humanoids like Tesla's Optimus prioritize anthropomorphism over function. Their delicate balance systems consume 2kW+ power during basic walks—Handle uses just 500W while jumping rails thanks to gyroscopic stabilization. Optimus's 45-pound payload pales against Handle's 330-pound crate lifting, making most humanoids impractical for heavy logistics.

Agility comparisons are brutal: Handle's backflip-capable joints and counter-rotating torso execute parkour moves impossible for stiff-hipped competitors. When Ford tested humanoids for part retrieval, they clocked 8 minutes per task; Handle prototypes did it in 90 seconds.

The Physics-Defying Tech Stack Powering Boston Dynamics Handle Robot

Balancing Brilliance: The Gyro and Counterweight System

Handle's secret weapon? Its 15kg flywheel gyroscope that maintains stability during acrobatic maneuvers. Unlike humanoids that constantly adjust foot placement, Handle's counter-rotating mass provides instant torque correction—allowing wheeled movement without toppling. This innovation alone reduces energy consumption by 40% compared to Honda's E2-DR.

Vision System: Seeing Beyond Lidar Limitations

While most robots rely solely on lidar for navigation, Handle combines stereo cameras with depth sensors for millimeter-precise grasping. This fusion lets it identify partially obscured objects—a task that stumps Amazon's Proteus robots. The system processes 30,000 3D points/second, enabling real-time adjustments mid-lift.

A: Absolutely. Handle's sealed joints and all-terrain wheels perform in rain, snow, and uneven surfaces where most warehouse robots fail. Boston Dynamics demonstrated this with outdoor box-stacking tests at -10°C.

A: While Handle's $250,000 price exceeds basic AGVs, its multi-function capability replaces multiple single-purpose machines. ROI analyses show 18-month payback periods in high-volume facilities—especially when considering Handle Robot Boston Dynamics: The Mind-Blowing Future of Warehouse Automation.

A: Handle's 2-hour runtime stems from regenerative braking—recapturing energy during descents. Competitors like Agility's Digit last just 45 minutes performing similar tasks, requiring more frequent charging cycles.

The Future Landscape: How Handle Redefines Robotics Standards

Handle's success has forced competitors to rethink fundamental assumptions. Toyota recently abandoned its humanoid project to explore wheel-leg hybrids, while FedEx now prioritizes dynamic mobility over fixed automation. The Boston Dynamics Handle Robot isn't just another product—it's a benchmark that's permanently elevated expectations for robotic capability.

As Handle evolves into Handle 2 (rumored to feature AI-driven swarm coordination), its influence will expand beyond logistics into construction, disaster response, and even space exploration. The age of single-purpose robots is ending, and Handle's hybrid revolution is leading the charge.

Conclusion: Why Handle Represents Robotics' Quantum Leap

The Boston Dynamics Handle Robot stands apart not through incremental improvements, but by shattering conventional design constraints. Its wheel-leg fusion, gyroscopic genius, and multi-modal intelligence create capabilities that make traditional robots look like relics. For businesses seeking automation that adapts rather than restricts, Handle isn't just different—it's in a league of its own.