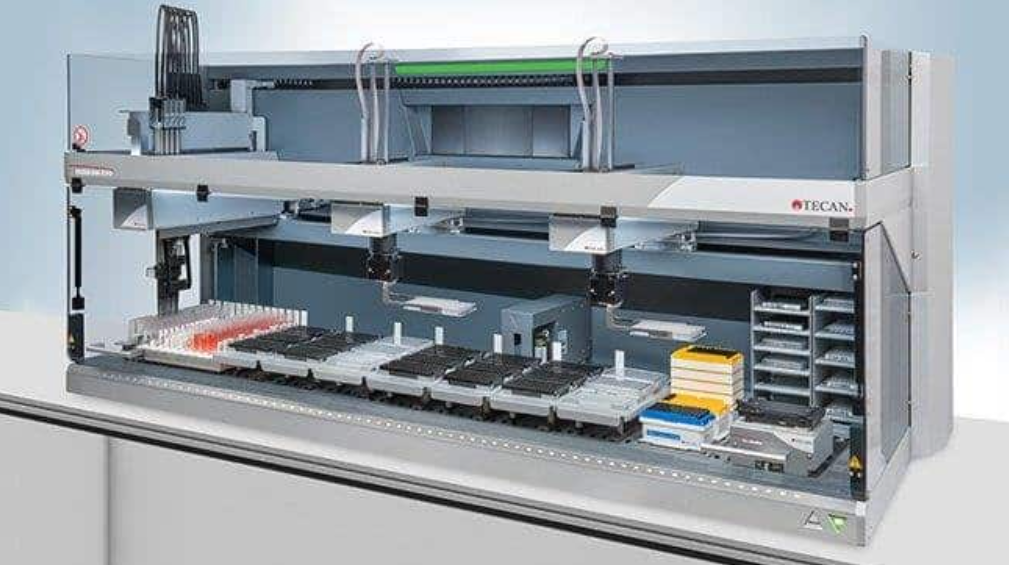

Imagine a lab technician, meticulously pipetting tiny droplets for hours, eyes strained, focus unwavering yet prone to inevitable human error. Now, imagine replacing that repetitive task with a machine capable of moving volumes smaller than a raindrop with pinpoint accuracy, tirelessly, 24/7. This isn't science fiction; it's the reality brought by Liquid Handling Robots. From accelerating life-saving drug discovery during global pandemics to enabling breakthroughs in genomics and personalized medicine, these robotic workhorses are revolutionizing laboratories worldwide. They are the often unseen, yet indispensable, force tackling the twin challenges of soaring research demands and crippling scientific labor shortages. Dive in as we unravel how Liquid Handling Robots work, why they're smarter than ever thanks to AI, and how they’re silently reshaping the future of science itself.

From Manual Pipetting to Robotic Mastery: A Revolutionary Transformation

The tedious task of manually transferring liquids – be it samples, reagents, or buffers – has long been the bottleneck in countless laboratories. Repetitive strain injuries, inconsistencies between technicians, and sheer time consumption hindered progress. The rise of Liquid Handling Robots marks a pivotal shift. Modern systems aren't just mechanical arms mimicking human motions; they are sophisticated instruments governed by software and increasingly powered by AI, achieving feats impossible for the human hand.

The impact was starkly evident during the COVID-19 pandemic. High-throughput testing demanded processing thousands of samples daily. Manual methods couldn't scale. Automated liquid handling platforms became frontline heroes, enabling the massive scale and speed required for global testing and vaccine development efforts. This crisis highlighted not just their utility, but their critical role in global health security.

Beyond pandemics, Liquid Handling Robots are fundamental in genomics (think library prep for next-generation sequencing), drug discovery (high-throughput screening of compound libraries), diagnostics, and synthetic biology. They handle everything from nanoliters for delicate PCR setups to milliliters for cell culture. The precision revolution they bring directly translates to faster discoveries, more reliable results, and freed-up human intellect for complex analysis.

Beyond The Pipette Tip: How Liquid Handling Robots Actually Work

At its core, a Liquid Handling Robot automates the aspiration (drawing in) and dispensing (releasing) of liquids. But achieving high precision consistently is a complex engineering feat.

Core Technologies Powering Precision

Aspiration & Dispensing Mechanisms:

Air Displacement Pipetting (Syringe-Based): Uses a piston moving within a cylinder to create air pressure changes, driving liquid movement through a disposable tip. Ideal for broad volume ranges and changing liquid types. Requires tip calibration for optimal accuracy.

Positive Displacement: The piston directly contacts the liquid via a disposable tip or syringe. Eliminates air cushion effects, providing superior accuracy for volatile, viscous (e.g., glycerol, blood), or foaming liquids. Less common but essential for specific applications.

Non-Contact Dispensing (Acoustic/Ejector): Utilizes focused sound waves (acoustic energy) or pressurized pulses to eject droplets directly from a source well without a physical tip touching the destination plate. Eliminates carryover contamination and tip costs, ideal for assays needing minimal dead volume (e.g., Beckman Coulter Echo).

Peristaltic Pumping: Uses rollers compressing flexible tubing to move fluid. Common for bulk reagent addition and continuous flow applications, less precise for microliter volumes.

Motion Control & Positioning: High-precision robotic arms or Cartesian gantries maneuver the pipetting head (or tips) with incredible accuracy (often micron-level positioning). Feedback sensors ensure correct placement.

Labware Handling: Integrated robotic arms or movable deck components automatically load/unload microplates, tubes, tip boxes, and other labware, enabling complex, unattended workflows. This is where integration with broader lab automation (Material Handling Robots) becomes crucial.

Sensors & Feedback: Liquid level detection sensors ensure tips aspirate consistently without sucking air. Force sensors detect tip picking, blockages, or collisions. Optical sensors monitor processes.

Software & Scheduling: Sophisticated scheduling software orchestrates every movement, timing, and action. Modern interfaces are increasingly intuitive, allowing complex protocol programming without deep coding knowledge.

Why Precision Matters: A Human vs. Robot Showdown

Consider a standard ELISA assay requiring identical reagent dispensing across 96 wells. A highly skilled human might achieve a Coefficient of Variation (CV – a measure of precision) of 5-10% between wells. A well-calibrated air displacement Liquid Handling Robot can consistently achieve CVs below 1-2%, especially for volumes above 5 microliters. This tighter precision directly reduces experimental noise, increases the reliability of data interpretation, and minimizes costly repeats using precious samples. For applications like serial dilutions or qPCR setup, robot precision isn't just better; it's often essential for trustworthy results.

The AI Infusion: Making Liquid Handling Robots Smarter

Traditional automation excels at programmed, repetitive tasks. The next evolution involves embedding intelligence, transforming Liquid Handling Robots from mere executors to adaptive collaborators. This is where Handling Robots: The Silent Revolution Transforming AI and Automation truly converges with liquid handling.

Key Areas of AI Integration:

Predictive Maintenance: Analyzing motor vibration patterns, tip usage data, and sensor logs using machine learning models allows the system to predict component failure (e.g., a failing syringe pump seal) *before* it happens, minimizing unexpected downtime.

Error Detection & Recovery: AI-powered computer vision can monitor liquid dispensing in real-time. It can detect anomalies like bubbles, splashes, or incorrect liquid levels in wells that traditional sensors might miss. Advanced systems can then autonomously initiate a recovery step (e.g., re-dispensing a specific well) rather than aborting the entire run.

Protocol Optimization: AI can analyze past protocol run times, pipetting paths, and labware movements to suggest optimizations for speed and efficiency. Could pipetting order be changed to reduce arm travel? Could reagent additions be batched differently? AI provides data-driven answers.

Adapting to Challenging Liquids: Machine learning models, trained on vast datasets of liquid properties (viscosity, surface tension) and dispensing outcomes, can fine-tune aspiration/dispense parameters (speed, acceleration, blow-out volume, tip touch settings) in real-time for difficult liquids. This moves beyond static calibration curves.

Process Control & Decision Making: In complex integrated workflows (e.g., automated cell culture), AI can analyze interim results (like cell growth images or sensor data) and dynamically adjust subsequent liquid handling steps (e.g., changing media composition or passaging schedule) without human intervention.

Choosing Your Robotic Lab Partner: Key Considerations

Selecting the right Liquid Handling Robot is crucial and depends heavily on specific needs.

Critical Factors:

Throughput Needs: How many samples/reactions per day or week? Low-throughput systems handle dozens of plates, while ultra-high-throughput platforms handle thousands.

Volume Range & Precision: What volumes are critical? Nanoliters (nL) for genomics? Microliters (μL) for ELISA? Milliliters (mL) for media prep? Required precision at those volumes? Demand proof (CV data).

Liquid Types: Will you handle only aqueous buffers, or also viscous, volatile, foaming, or precious samples? Dictates aspiration technology.

Labware Compatibility: Which microplates (96-well, 384-well? Deep well?), tube racks, tip boxes, reservoir troughs do you use? Ensure seamless integration.

Integration Level:

Standalone: Handles specific liquid tasks; samples moved manually.

Semi-Automated Workstation: Combines liquid handling with 1-2 other modules (e.g., plate reader, washer).

Fully Automated System: Fully integrated with conveyors, storage hotels, incubators (Material Handling Robots are key here), capable of running days unattended.

Software & Usability: Is the interface intuitive? Does it support easy protocol creation, editing, and scheduling? How steep is the learning curve?

Flexibility vs. Dedicated Use: Need a system reprogrammable for various tasks, or dedicated solely to one high-volume assay?

Deck Size & Footprint: Physical space available in the lab is always a constraint.

Total Cost of Ownership (TCO): Look beyond the sticker price. Factor in consumables (tips), maintenance contracts, potential integration costs, technician training time, and expected lifespan.

The Horizon: What's Next for Liquid Handling Robots?

The evolution is far from over. Several key trends are shaping the future:

Massively Miniaturized Volumes & Nanodroplets: Pushing dispensing precision into the picoliter (pL) range using refined acoustic or microfluidic technologies. Enables ultra-high-density assays on microchips or specialized surfaces.

Advanced On-Demand Synthesis Integration: Tight coupling of robotic liquid handlers with chemical synthesizers. Robots precisely dispense precursors, initiate reactions, purify products, and transfer the final compound for screening – all within a closed loop. Accelerates materials science and drug discovery.

Deeper AI & Closed-Loop Feedback: AI won't just react to errors; it will proactively design experiments. Imagine specifying a desired biological outcome (e.g., "maximize protein yield"), and an AI-driven liquid handler autonomously tests combinations of media components, feeding schedules, and conditions via continuous feedback from sensors and interim analyses.

Enhanced Multi-omics Integration: Seamless workflows that combine liquid handling for genomics (DNA/RNA extraction), proteomics (protein handling), and metabolomics (metabolite extraction) on the same platform, minimizing sample transfer and degradation.

Democratization Through Modularity & Lower Cost: More modular, benchtop systems making automation accessible to smaller labs and core facilities with smaller budgets. Open-source robotics software might play a role.

Human-Robot Collaboration (Cobots): Collaborative robots working safely alongside humans, handling specific liquid handling tasks within a shared lab space under the scientist's guidance.

Addressing the Elephant in the Lab: ROI and Integration

Investment in Liquid Handling Robots is significant. Justifying it requires a clear view of Return on Investment (ROI). Look beyond pure throughput numbers:

Reduced Errors & Repeats: Quantify the cost of failed experiments due to manual pipetting errors. Robots drastically reduce this.

Staff Productivity: Freeing highly trained scientists from hours of repetitive tasks allows them to focus on experimental design, data analysis, and innovation – tasks with higher intrinsic value.

Consistency & Data Quality: Highly reproducible data enhances publication quality, grant proposals, and regulatory submissions.

Scalability: Can your research *scale* without automation? Often, the answer is no.

Sample Integrity: Reduced handling minimizes contamination risk and sample degradation, critical for sensitive assays.

Integration complexity is another real concern. Start small if needed. A standalone liquid handler for the most repetitive, high-error task is a valid entry point. Plan carefully for larger integrations: ensure vendors provide robust integration software support, and consider the expertise needed to manage the system. Robust training is non-negotiable.

Frequently Asked Questions (Liquid Handling Robots)

Q: Can Liquid Handling Robots completely replace human lab technicians?

A: Not entirely. While incredibly efficient at standardized, high-volume liquid transfer tasks, human expertise remains vital for tasks requiring complex judgment, troubleshooting unexpected problems, experimental design, interpreting results, and maintaining the robotic systems themselves. Robots augment human capabilities, allowing scientists to focus on higher-value work.

Q: How significant is the contamination risk with reusable tips vs. disposable tips?

A: The risk is substantial, which is why disposable tips are the standard for almost all applications involving different samples or reagents. Carryover between samples, even minute amounts, can ruin experiments. Non-contact dispensing (acoustic) eliminates this risk entirely. Some highly specialized positive displacement systems might use washable tips with rigorous cleaning validation for specific, single-reagent processes, but disposables dominate.

Q: My lab budget is tight. Is there an affordable entry point for automation?

A: Yes! The market now offers several cost-effective options:

Electronic Pipettes: Not full robots, but provide electronic control and multi-dispensing.

Benchtop Single-Channel/Multi-Channel Pipetting Stations: Affordable units automating the movement of a pipette across a plate. Good for specific, moderate-volume tasks.

Refurbished Systems: Reputable vendors offer refurbished liquid handlers with warranties at lower costs.

Core Facility Access: Utilize shared robotics resources within your institution.

Q: Are Liquid Handling Robots difficult to program?

A: Difficulty varies significantly. Modern platforms have greatly improved graphical user interfaces (GUIs). Instead of writing complex code, users often use intuitive drag-and-drop interfaces to build protocols using pre-configured liquid handling steps. Training is still essential for efficient and error-free programming, but the barrier to entry is lower than ever. Some highly complex or novel protocols might still require scripting expertise.

Conclusion: Embracing the Precision Revolution

Liquid Handling Robots have transcended their origins as mere pipetting aids. They are fundamental drivers of scientific progress, enabling research at a scale and precision unthinkable just decades ago. Their integration with AI is unlocking even greater capabilities – adaptability, intelligent error handling, and predictive power. While challenges like cost, integration complexity, and workforce adaptation remain, the benefits of reduced errors, enhanced reproducibility, accelerated discovery, and liberated human potential are undeniable. From diagnosing diseases faster to creating life-saving therapies and unraveling the complexities of biology, these sophisticated machines are not just tools; they are indispensable partners in shaping a healthier, smarter future. The lab revolution is automated, precise, and already here.