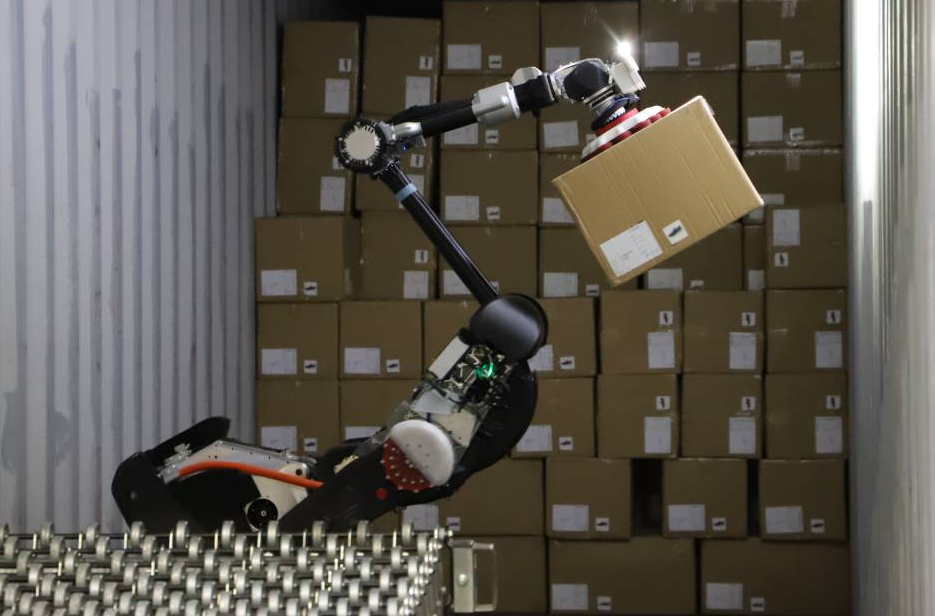

Imagine a factory floor where heavyweight components glide through assembly lines with ballet-like precision, guided not by human hands but by intelligent machines with sub-millimeter accuracy. This isn't science fiction—it's the reality Handling Robots are creating today. As the unsung heroes of industrial automation, these mechanical powerhouses handle everything from microscopic silicon wafers to multi-ton automobile frames, transforming industries while operating in near-total silence. In this deep dive, we'll unveil how their fusion of brute strength and artificial intelligence is solving humanity's most physically demanding tasks—and why their evolution will fundamentally reshape our relationship with machines.

What Exactly Are Handling Robots?

Handling Robots represent a specialized class of industrial automation systems engineered primarily for material transfer, positioning, and manipulation tasks. Unlike their assembly-line cousins, these machines prioritize payload capacity, reach, and adaptive control over delicate tasks. From palletizing 2,000-pound cargo stacks to gently placing smartphone displays, their versatility stems from sophisticated sensor suites and increasingly intelligent motion planning algorithms. The core architecture typically integrates robust articulated arms mounted on linear tracks or gantry systems, creating volumetric workspaces where human labor would be impractical or hazardous.

The Mechanical Backbone: How Physics Meets Precision

At their most fundamental level, Handling Robots operate through a marriage of rigid body kinematics and actuator control systems. Industrial models typically feature 4-6 rotational axes powered by brushless DC servo motors, delivering torque outputs exceeding 500 Nm in heavy-duty variants. What makes modern iterations revolutionary is their compliance control—hydraulic counterbalance systems and torque sensors allow "muscle memory" adjustments when encountering unexpected resistance. For example, Fanuc's M-2000iA/1700L can lift a full-sized car while detecting minute obstacles through current fluctuations in its joints, automatically recalculating paths without human intervention.

End Effectors: The Specialized Hands

No discussion of Handling Robots is complete without examining their End-of-Arm Tooling (EOAT). These interchangeable interfaces range from vacuum cup arrays handling glass panels to electromagnetic grippers moving engine blocks. Advanced EOAT now incorporates vision-assisted alignment—ABB's PixelGrip system uses microscopic cameras embedded in suction cups to detect surface irregularities, adjusting vacuum pressure dynamically across hundreds of zones. This evolution from dumb clamps to sensory appendages represents a quantum leap in handling capability, enabling single robots to manipulate vastly different objects without retooling downtime.

The AI Transformation: Beyond Repetition to Adaptation

First-generation Handling Robots followed rigidly programmed paths, but today's generation interprets environments through sensor fusion. Lidar scanners create real-time 3D occupancy maps while torque sensors detect load imbalances—data streams processed through on-board neural networks. Kuka's AIV models exemplify this shift, using predictive analytics to anticipate conveyor speeds and package trajectories. When an unexpected package tumble occurs, path-replanning algorithms generate collision-free trajectories within 500 milliseconds. This contextual awareness transforms material handling from automated to truly autonomous.

Tactile Intelligence: The Next Frontier

While vision systems dominate innovation discussions, the emergence of synthetic tactile intelligence marks perhaps the most radical advancement for Handling Robots. Researchers at MIT's CSAIL recently demonstrated "skin" for robotic grippers—flexible matrices of piezoresistive sensors detecting pressure differentials as minute as 0.1 N/cm2. Combined with reinforcement learning, robots can now distinguish between ripe and unripe fruit based on deformation feedback during grasping. This sensory revolution enables handling tasks previously considered impossible for machines: assembling delicate electronics cables or loading fragile glassware onto dish racks with human-like care.

Unseen Applications Revolutionizing Industries

Beyond factory floors, specialized Handling Robots operate in environments hostile to human presence. In nuclear decommissioning facilities, remotely operated manipulators handle radioactive debris behind 4-foot thick leaded glass. Offshore oil platforms employ explosion-proof robotic cranes that transfer equipment in hurricane-force winds. Even biotechnology labs utilize micro-handling robots placing individual stem cells using micro-pipettes with 0.5-micron precision—equivalent to manipulating a single grain of salt under microscope guidance.

Extreme Environment Handlers: Earth and Beyond

Remarkably, Handling Robots engineered for terrestrial extremes provide blueprints for extraterrestrial applications. The mechanical architectures developed for deep-sea manipulators capable of withstanding 500-bar pressures directly inform designs for potential Europa ocean explorers. Marine Robot Interstellar initiatives prove how Earth's ocean tech could unlock alien oceans, with submersible handlers sampling hydrothermal vents autonomously—a capability transferrable to ice-moon exploration. This crossover demonstrates how handling technology pushes boundaries beyond industrial realms into planetary science.

Economic Impacts and Productivity Metrics

Deploying Handling Robots yields quantifiable efficiency transformations. Automotive plants like BMW's Spartanburg facility report 87% reduction in component damage during transfer since implementing AI-driven handlers. Warehouse automation shows even starker gains: Amazon's robotic fulfillment centers move 35% more packages per hour with 50% fewer handling errors than manual equivalents. Critically, these systems alleviate the $100B+ global problem of workplace musculoskeletal disorders by assuming high-risk repetitive motions. While upfront investments average $70,000-$400,000 per unit, typical ROI periods have compressed from 5 years to under 18 months due to these combined benefits.

Collaborative Robotics: Humans and Handlers Coexisting

The rise of cobots has transformed Handling Robots from segregated systems to interactive partners. Universal Robots' UR16e model exemplifies this shift—featuring force-limited joints and 3D presence sensing allowing direct human collaboration. Workers now guide these handlers through physical demonstration for new tasks rather than programming. This tactile programming approach has reduced deployment times by 90% in SMEs while simultaneously improving human worker satisfaction scores by 63% in Airbus case studies. Such collaboration represents the true democratization of robotic handling.

Future Evolution: Where Machine Learning Meets Muscle

Looking forward, Handling Robots will evolve beyond task executors to predictive partners through AI integration. Digital twin technology already creates simulation sandboxes where handling scenarios undergo millions of virtual trials before physical implementation. Generative design algorithms now optimize robot structures impossible to conceive manually—researchers recently demonstrated grippers with fractal structures that distribute stress across organic lattice patterns. Most transformatively, large language models enable natural speech commanding: technicians can instruct "Shift those crates to the northeast corner gently" rather than coding waypoints. This symbiosis of cognition and physical capability will redefine what handling automation means.

Addressing Safety Paradoxes

As Handling Robots gain autonomy, critical safety paradoxes emerge. Systems must simultaneously achieve forceful manipulation and gentle responsiveness—a balance addressed through new standards like ISO/TS 15066 covering collaborative applications. Emerging safety-rated soft robotics utilize air-filled elastomers and jamming transitions for inherently safe manipulation. Festo's latest grippers can shatter a lightbulb then immediately handle an uncooked egg by altering material states through granular jamming physics. This fundamental rethinking of manipulation mechanics demonstrates how physical safety will remain paramount even with cognitive advances.

Frequently Asked Questions

What's the difference between a Handling Robot and other industrial robots?

Handling Robots specialize specifically in material transfer, positioning, and pick-and-place operations—optimizing for payload capacity, reach, and orientation flexibility. Unlike welding or assembly robots, their strength lies in rapid adaptation between disparate object types rather than performing precise repetitive manufacturing tasks.

Can Handling Robots operate safely alongside human workers?

Absolutely. Modern collaborative handlers incorporate ISO-certified safety features like force limitation (typically below 150N), speed monitoring, and 3D vision-based presence detection. Systems like ABB's YuMi and Fanuc's CR series detect contact within milliseconds and can stop motion before causing injury—enabling truly integrated workflows.

How is AI specifically enhancing Handling Robots capabilities?

AI provides three revolutionary advancements: 1) Computer vision systems that recognize object orientation under variable lighting/presentation; 2) Predictive models forecasting load dynamics using historical data; and 3) Reinforcement learning algorithms that optimize gripping strategies through simulation—reducing trial-and-error programming from weeks to hours.

The Invisible Infrastructure Revolution

What's most remarkable about the Handling Robot revolution is its invisibility. While humanoid robots capture headlines, these specialized machines transform global supply chains without fanfare. They load the ships, pack the boxes, and build the structures that define modern civilization—operating increasingly not through rigid programming, but contextual intelligence. As AI merges with mechanical brawn, they're becoming less tools and more collaborative partners in humanity's physical endeavors. The quiet whir of their servos signals not displacement, but augmentation—freeing human potential from the tyranny of repetitive strain. In this silent revolution, the handling robots working in factory shadows today are building the template for our collaborative tomorrow.