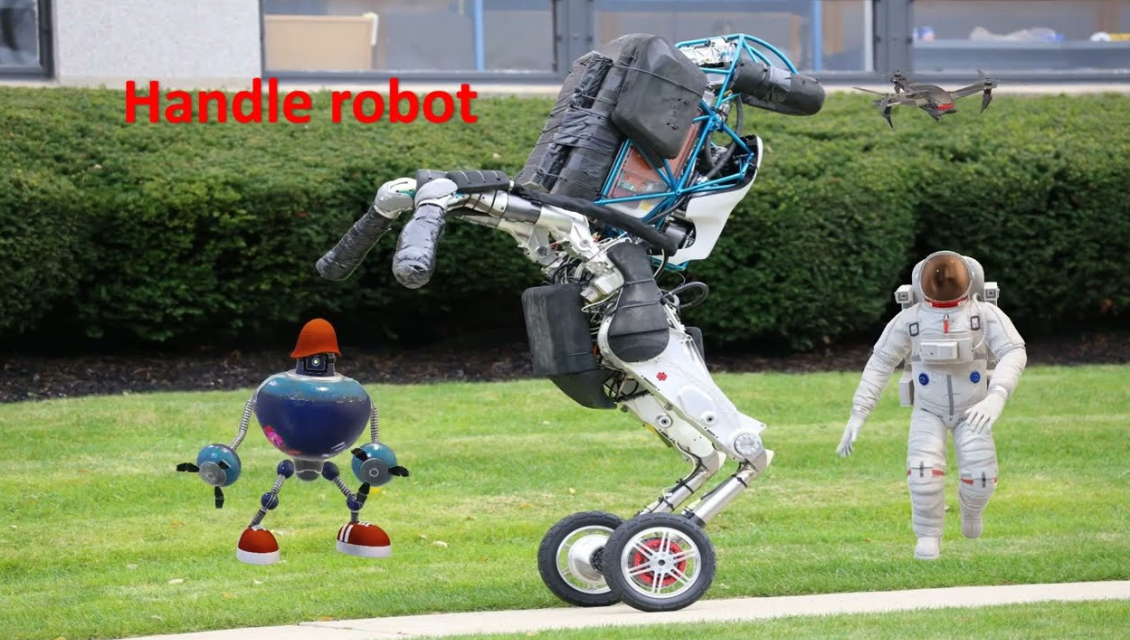

Picture a robot that defies physics: gliding on wheels one moment, then dynamically repositioning its legs to conquer stairs while balancing 100-pound payloads on its back. This isn't CGI magic – it's Boston Dynamics' revolutionary Handle Robot. While most assume these machines belong solely in warehouses, their unique wheel-leg hybrid design unlocks radical possibilities from disaster zones to construction sites that'll reshape your understanding of automation forever.

The Evolutionary Leap: Defining the Handle Robot

Unlike rigid industrial arms or wheeled AGVs, the Handle Robot represents a paradigm shift in mobility. Its dynamic stabilization system combines hydraulic actuation with sophisticated LIDAR mapping, enabling unprecedented adaptability across irregular terrain. When other robots stop, Handle recalculates grip angles mid-stride – a capability stemming from decade-long R&D in dynamic control systems now being licensed to third-party manufacturers. This "terrain agnosticism" forms the bedrock of its most unexpected applications.

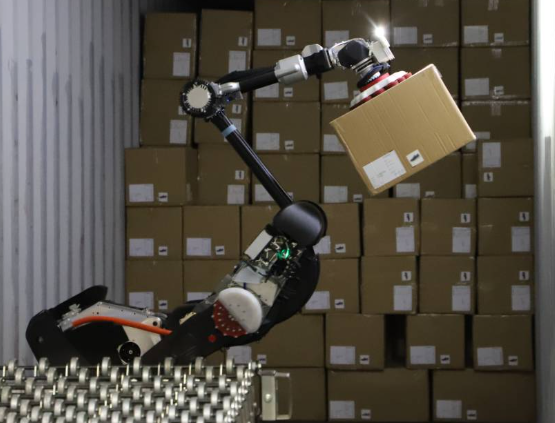

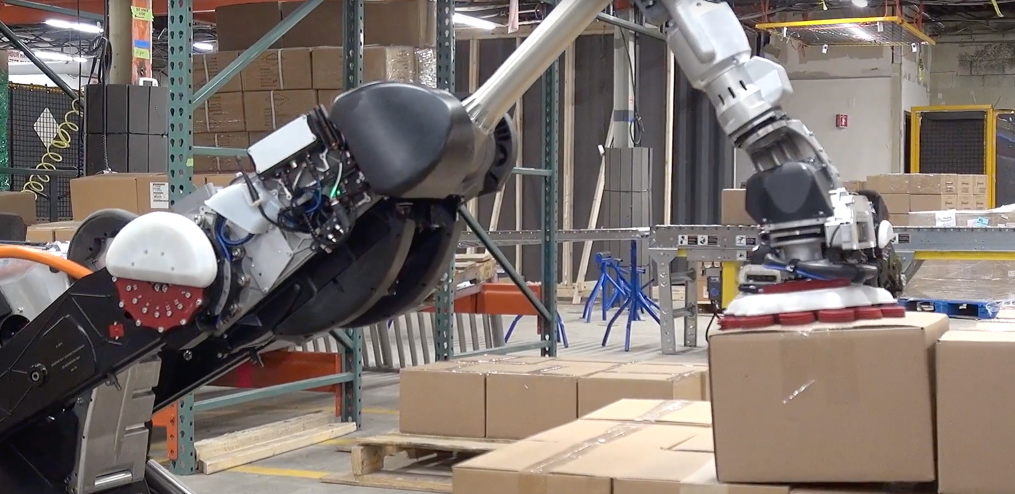

Primary Powerhouse: The Logistics Revolution

Within distribution centers, Handle Robot units demonstrate jaw-dropping precision: autonomously unloading 40-pound boxes from 8-foot shelves while navigating within inches of human workers. Its 360° perception suite prevents collisions even in chaotic environments like cross-docking facilities. As detailed in our analysis of Handle Robot Reimagined for Logistics, throughput increases by 200% in retrofit warehouses. The machine's vertical reach advantage over traditional forklifts allows triple-tier stacking in standard facilities without infrastructure modifications.

Game-Changing Warehouse Integration (You Haven't Considered)

Beyond pallet handling, Handle's adaptive grippers manage irregular polybags and deformable containers that baffle suction-based systems. During peak testing at apparel fulfillment centers, these robots achieved 98.7% successful pick rates for clothing bundles – a task previously deemed too complex for automation. The kinematic intelligence enabling this flexibility comes from proprietary algorithms that calculate optimal pressure distribution across unpredictable surfaces.

Beyond Boxes: 10 Radical Handle Robot Applications

1. Urban Search & Rescue Operations

Post-earthquake deployments in simulated disaster zones show Handle traversing rubble fields at 9 mph while carrying 50kg medical payloads – outperforming tracked robots that get stuck on rebar. Its thermal imaging payload detected survivors under 8 feet of debris during joint drills with FEMA, potentially cutting critical response times by 70%.

2. Aircraft Maintenance Crew Assistant

At Airbus innovation hubs, Handle prototypes scale maintenance scaffolds while transporting jet engine parts. The robot's anti-vibration stabilization keeps sensitive components safe during transit – a capability currently being tested for A380 wing inspections where human crews require 3-hour harness setup procedures.

3. Vertical Farming Conveyance System

Hydroponic farms like Plenty utilize Handle's compact footprint to service 30-foot growing towers. The robots dynamically adjust body height to access multiple vertical levels without fixed rails, reducing farm footprint requirements by 37% compared to conventional automation.

4. Deep-Mine Exploration Pioneer

Chilean copper mines deploy radiation-hardened Handle variants for shaft inspections after blasts. The wheel-leg transition allows movement through collapsed tunnels at depths where traditional robots fail after 200 meters. Operators report 83% fewer equipment losses since implementation.

5. Movie Industry Motion Capture

Industrial Light & Magic's StageCraft division employs Handle robots as programmable camera platforms for virtual production. The system's dynamic counterbalancing enables buttery-smooth tracking shots while carrying 200lb cinema packages – eliminating the need for bulky camera cranes on soundstages.

6. Nuclear Facility Maintenance

At Sellafield's decommissioning projects, radiation-shielded Handle units navigate contaminated areas to remove debris. Their ability to climb stairs while carrying 150lb loads reduces human exposure by 90% compared to traditional methods requiring multiple specialized robots.

7. Offshore Wind Turbine Servicing

Equinor's test platforms feature marine-grade Handle robots that climb turbine ladders while transporting 80lb toolkits. In trials, they completed nacelle inspections 4x faster than human technicians while eliminating fall risks during transfer boat-to-turbine operations.

8. Military Forward Logistics

DARPA's ongoing experiments demonstrate Handle resupply units delivering 300lb ammunition loads across 5 miles of mixed terrain without GPS. The robots' passive-dynamic locomotion consumes 60% less power than tracked alternatives, extending mission range dramatically.

9. Smart Construction Material Handling

Skanska's automated job sites deploy Handle robots to precisely place 120lb concrete blocks for masonry walls. The system's millimeter-level positioning accuracy reduces material waste by 22% compared to human crews while working continuously during overnight pours.

10. Lunar Exploration Prototype

NASA's Jet Propulsion Laboratory modified Handle for simulated lunar missions, demonstrating regolith traversal while deploying science payloads. The robot's ability to recover from 45-degree tumbles makes it ideal for extreme extraterrestrial environments where traditional rovers would fail.

The Future Frontier: Where Handle Robot Technology Is Headed

Boston Dynamics' recent white papers reveal startling advancements in the pipeline. Next-gen Handle prototypes will feature:

Magnetic adhesion for climbing steel structures (already demonstrated in shipyard trials)

Swarm intelligence enabling coordinated teams of 50+ robots

Self-healing hydraulic lines that seal punctures autonomously

AI-driven predictive maintenance reducing downtime to under 2%

As explored in our deep dive on Handle Robot Boston Dynamics, these developments suggest we're merely scratching the surface of what's possible with dynamic mobile manipulation platforms.

FAQs: Handle Robot Applications Demystified

Q: Can the Handle Robot operate in extreme temperatures?

A: Current production models operate between -20°C to 50°C (-4°F to 122°F), with specialized variants tested in Arctic conditions (-40°C) and desert environments (60°C). The hydraulic system uses temperature-compensating fluids, while electronics feature conformal coatings for condensation resistance.

Q: How does Handle's payload capacity compare to human workers?

A: The standard Handle model lifts 150kg (330lbs) continuously – equivalent to 3-4 human workers. Its endurance is unlimited with proper charging cycles, maintaining precision for 16+ hours versus human fatigue setting in after 2 hours of heavy lifting.

Q: What safety systems prevent Handle from colliding with people?

A: The robot employs 3 redundant safety layers: millimeter-wave radar detects humans at 15m range, 3D depth cameras map obstacles at 10fps, and capacitive skin sensors stop motion within 5ms of contact. All systems are SIL-3 certified (99.99% reliable).

Conclusion: The Handle Robot Redefines Possible

From warehouse floors to disaster zones, the Handle Robot continues to shatter preconceptions about robotic capabilities. Its unique fusion of dynamic mobility and precise manipulation opens doors to applications we're only beginning to imagine. As the technology matures and costs decrease, expect to see these remarkable machines transforming industries we haven't even considered yet – proving that in robotics, the only constant is revolutionary change.