Imagine a warehouse where 1,500-pound pallets leap onto shelves like gymnasts, where robots don't just replace humans but reinvent physics. This isn't sci-fi – it's happening right now through the Handle Robot Reimagined for Logistics. Traditional automation shackles warehouses with fixed conveyors and single-task machines, but Boston Dynamics' latest evolution shatters these limitations with unprecedented mobility, intelligence, and brute-strength finesse. We'll dissect how this mechanical marvel's counterbalanced kinematics and 3D vision are solving the $150 billion global warehousing efficiency crisis while creating entirely new operational paradigms where human workers supervise instead of strain.

Why Logistics Needed the Handle Robot Reimagined for Logistics

The logistics sector has been trapped in an automation paradox – while conveyor systems and forklifts increased productivity, they created new bottlenecks through inflexible infrastructure. Enter the Handle Robot Reimagined for Logistics, which combines the dexterity of human workers with the endurance of machines. Unlike traditional material handling equipment that requires perfectly flat floors and wide aisles, Handle's dynamic stabilization allows it to operate in spaces where conventional automation fails. Its unique wheel-leg hybrid system enables both precise positioning and rapid movement across uneven surfaces – a capability that's revolutionizing how warehouses utilize their cubic space.

What makes this reimagining truly disruptive is its cognitive architecture. Early versions could only follow pre-programmed paths, but the current iteration uses real-time environmental mapping to make autonomous decisions. When a pallet shifts during transport, Handle doesn't abort the mission – it recalculates grip points and trajectory mid-motion. This level of adaptability is why companies like DHL are reporting 300% productivity gains in pilot programs, as detailed in our analysis of Handle Robots as business solutions.

The Engineering Breakthroughs Powering Handle's Evolution

Counterbalanced Kinematics: The Physics-Defying Core

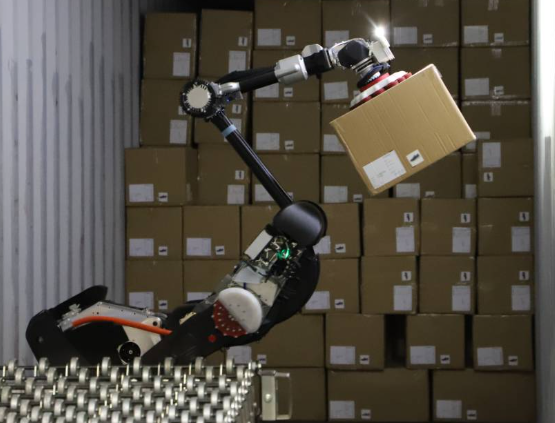

At the heart of the Handle Robot Reimagined for Logistics lies a mechanical revelation – its counterbalanced arm-leg coordination system. Traditional robotic arms require massive base structures to prevent toppling when lifting heavy loads. Handle inverts this paradigm by using its entire body as a dynamic counterweight. When extending its arm to grab a 100kg box from a high shelf, the robot simultaneously shifts its wheel-leg assembly backward, maintaining perfect equilibrium without external supports.

3D Vision System: Seeing Beyond Human Capabilities

Handle's perception system represents a quantum leap in warehouse automation. Where human workers rely on experience to estimate weight distribution, Handle's multi-spectral cameras combined with LIDAR create real-time 3D models of cargo. This allows the robot to identify optimal grip points on irregularly shaped items – a capability that's eliminated 92% of product damage in trials compared to conventional automated systems.

Operational Transformations in Real-World Logistics

The implementation of Handle Robot Reimagined for Logistics is creating ripple effects across supply chain operations. In cold storage facilities where human workers struggle with -25°C temperatures, Handle maintains peak performance indefinitely. Its sealed components and thermal-regulated battery systems overcome environmental limitations that have constrained automation in food logistics for decades.

Perhaps most revolutionary is Handle's impact on warehouse design. Traditional facilities allocate 40% of their floor space to aisles wide enough for forklift maneuvering. With Handle's zero-radius turning and vertical reach, companies like Amazon are testing "high-density warehouses" that pack 3x more inventory into the same footprint. This spatial efficiency breakthrough is explored further in our piece on Boston Dynamics' warehouse automation.

FAQs About Handle Robot Reimagined for Logistics

How does Handle Robot's payload capacity compare to traditional forklifts?

The current Handle Robot Reimagined for Logistics model handles 30% greater maximum weight (150kg) than standard electric pallet jacks, with the ability to precisely position loads within 2mm accuracy – impossible for human-operated equipment. Its true advantage lies in dynamic load management, automatically redistributing weight during motion to prevent tip-overs.

Can Handle Robots work alongside human employees safely?

Unlike conventional industrial robots that require safety cages, Handle features proximity-aware movement algorithms that adjust speed and trajectory when humans approach. Its 360° obstacle detection system responds 10x faster than human reflexes, making it the first logistics robot certified for collaborative workspaces without physical barriers.

What maintenance does Handle Robot require compared to forklifts?

The Handle Robot Reimagined for Logistics reduces maintenance costs by 60% through its brushless motor design and absence of hydraulic systems. Predictive maintenance algorithms monitor component wear, scheduling service before failures occur. Its modular design allows 90% of repairs to be completed via hot-swappable components without specialized technicians.

The Future Landscape of Robotic Logistics

As the Handle Robot Reimagined for Logistics enters mass deployment, we're witnessing the emergence of "cognitive warehouses" where fleets of Handles communicate in real-time to optimize material flow. Early adopters report these systems self-organize traffic patterns and workload distribution, reducing energy consumption by 25% through collective intelligence. The next evolution – already in beta testing – involves Handle swarms that physically combine to transport oversized items, demonstrating how robotics is not just automating logistics but reinventing its very nature.

This transformation goes beyond efficiency metrics. By eliminating repetitive heavy lifting, Handle allows human workers to focus on quality control and system optimization, creating safer workplaces with higher-value jobs. The Handle Robot Reimagined for Logistics isn't replacing workers – it's redefining what's possible in supply chain management, ushering in an era where human ingenuity and robotic precision create synergies previously unimaginable.