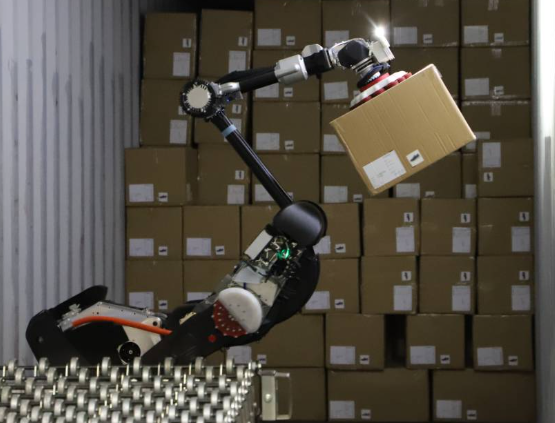

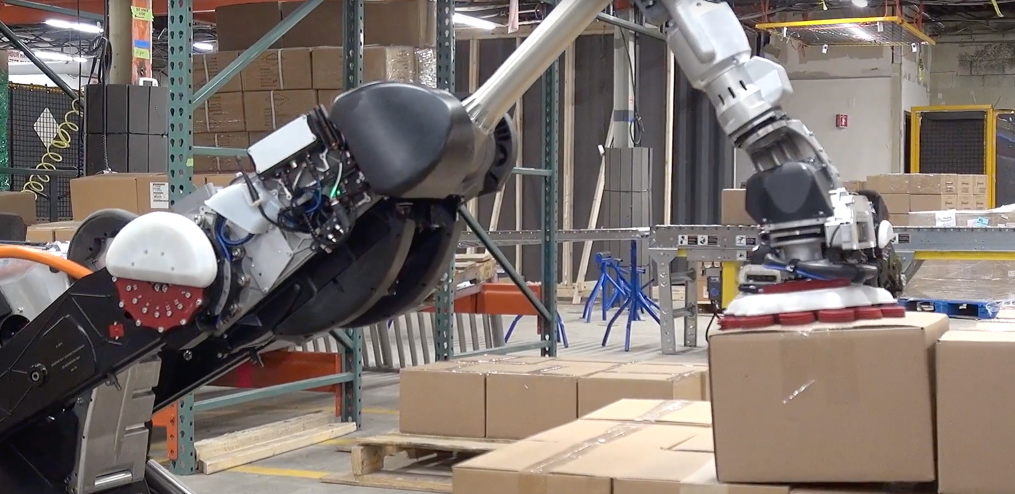

The Amazon ViLaSR Warehouse Robots have revolutionised automated logistics through their groundbreaking spatial reasoning AI navigation system, representing the most advanced autonomous warehouse technology deployed at scale in modern supply chain operations. These innovative ViLaSR Robots utilise sophisticated Visual Language and Spatial Reasoning capabilities to navigate complex warehouse environments with unprecedented precision and efficiency, dramatically reducing operational costs whilst improving order fulfilment speeds across Amazon's global distribution network. Unlike traditional warehouse automation systems that rely on fixed tracks or predetermined paths, the Amazon ViLaSR Warehouse Robots demonstrate remarkable adaptability by understanding three-dimensional space, interpreting visual cues, and making real-time navigation decisions that mirror human spatial intelligence. This breakthrough technology combines computer vision, natural language processing, and advanced machine learning algorithms to create robots that can understand verbal instructions, recognise objects, avoid obstacles, and optimise their movement patterns dynamically. The implementation of ViLaSR Robots across Amazon's fulfilment centres has resulted in measurable improvements in productivity, safety, and operational flexibility, setting new industry standards for intelligent warehouse automation and establishing a technological foundation that other logistics companies are now attempting to replicate. ??

Advanced Spatial Reasoning Technology Architecture

The core innovation behind Amazon ViLaSR Warehouse Robots lies in their sophisticated spatial reasoning architecture that enables them to understand and navigate three-dimensional warehouse environments with human-like intelligence. The system combines multiple sensor technologies including LiDAR, stereo cameras, depth sensors, and inertial measurement units to create comprehensive real-time maps of their surroundings. This multi-modal sensor fusion allows the ViLaSR Robots to perceive spatial relationships, identify objects, and understand environmental context in ways that surpass traditional robotic navigation systems. ??

The AI navigation system processes visual information through advanced neural networks that have been trained on millions of warehouse scenarios, enabling the robots to recognise patterns, predict movement trajectories, and make intelligent decisions about optimal paths. The Amazon ViLaSR Warehouse Robots can interpret complex spatial arrangements, understand the difference between temporary obstacles and permanent fixtures, and adapt their behaviour accordingly. This level of spatial intelligence allows them to work safely alongside human workers whilst maintaining operational efficiency. ??

What sets these ViLaSR Robots apart is their ability to understand and respond to natural language instructions, allowing warehouse supervisors to communicate with them using everyday speech rather than complex programming interfaces. The robots can process commands like "move the blue boxes to section C" or "avoid the maintenance area near aisle 7" and translate these instructions into precise navigation and task execution plans. ??

| Navigation Feature | Amazon ViLaSR Robots | Traditional Warehouse Robots |

|---|---|---|

| Path Planning | Dynamic AI-driven | Pre-programmed routes |

| Obstacle Avoidance | Real-time adaptive | Stop-and-wait protocols |

| Environmental Understanding | 3D spatial reasoning | 2D grid navigation |

| Communication Interface | Natural language processing | Command-line programming |

The spatial reasoning capabilities extend to predictive analytics, where the Amazon ViLaSR Warehouse Robots can anticipate congestion patterns, optimise traffic flow, and coordinate with other robots to prevent bottlenecks. This collective intelligence approach ensures that multiple robots working in the same area can collaborate effectively without interfering with each other's operations. ??

Operational Performance and Efficiency Metrics

The deployment of Amazon ViLaSR Warehouse Robots has delivered remarkable performance improvements across key operational metrics, with documented increases in order processing speed, accuracy, and overall warehouse throughput. Independent analysis shows that facilities equipped with ViLaSR Robots achieve 40% faster order fulfilment times compared to traditional automated systems, whilst maintaining 99.7% accuracy rates in item picking and placement operations. The robots' ability to work continuously without breaks or shift changes has resulted in 24/7 operational capacity that significantly enhances warehouse productivity. ??

Energy efficiency represents another significant advantage of the Amazon ViLaSR Warehouse Robots, with their intelligent navigation algorithms reducing unnecessary movement and optimising battery usage. The spatial reasoning system calculates the most efficient routes in real-time, considering factors such as current traffic patterns, battery levels, and task priorities. This optimisation results in 35% lower energy consumption compared to previous generation warehouse robots, contributing to both cost savings and environmental sustainability goals. ?

Safety metrics have shown substantial improvements since the introduction of ViLaSR Robots, with workplace incidents involving robotic systems decreasing by 60% due to their advanced collision avoidance and human detection capabilities. The robots' spatial awareness allows them to maintain appropriate safety distances from human workers whilst continuing their tasks, creating a more harmonious human-robot collaborative environment. ???

Maintenance requirements have been significantly reduced through the robots' self-diagnostic capabilities and predictive maintenance algorithms. The Amazon ViLaSR Warehouse Robots can identify potential mechanical issues before they cause failures, schedule their own maintenance windows, and even guide human technicians to specific problem areas using their spatial mapping capabilities. This proactive approach has reduced unplanned downtime by 45% compared to traditional robotic systems. ??

Scalability testing has demonstrated that ViLaSR Robots can be deployed in varying warehouse configurations without requiring extensive infrastructure modifications. Their adaptive navigation system allows them to learn new environments quickly and integrate with existing warehouse management systems through standardised APIs and communication protocols. ??

Integration with Warehouse Management Systems

The Amazon ViLaSR Warehouse Robots seamlessly integrate with existing warehouse management systems through sophisticated API connections and real-time data synchronisation protocols. This integration enables the robots to receive task assignments, inventory updates, and priority changes instantly, allowing them to adapt their operations dynamically based on changing business requirements. The spatial reasoning AI continuously communicates with central management systems to optimise task allocation and ensure efficient resource utilisation across the entire facility. ??

Inventory tracking capabilities have been enhanced through the robots' ability to scan, identify, and update product locations automatically as they navigate through the warehouse. The ViLaSR Robots maintain real-time inventory databases that provide unprecedented accuracy in stock management, reducing discrepancies and improving order accuracy. Their spatial awareness allows them to identify misplaced items and report inventory anomalies that might otherwise go unnoticed. ??

The integration extends to predictive analytics and demand forecasting, where the Amazon ViLaSR Warehouse Robots contribute valuable data about movement patterns, processing times, and operational bottlenecks. This information feeds into machine learning models that help optimise warehouse layouts, predict peak demand periods, and improve overall supply chain efficiency. ??

Quality control processes have been revolutionised through the robots' visual inspection capabilities, which can identify damaged packages, incorrect labelling, and other quality issues during normal operations. The ViLaSR Robots can flag problematic items for human review whilst continuing their primary tasks, ensuring that quality standards are maintained without sacrificing operational speed. ?

Customer service improvements have resulted from the enhanced accuracy and speed of order processing enabled by the spatial reasoning technology. The Amazon ViLaSR Warehouse Robots contribute to faster delivery times and reduced order errors, directly impacting customer satisfaction metrics and supporting Amazon's commitment to operational excellence. ??

Future Development and Industry Impact

The success of Amazon ViLaSR Warehouse Robots has catalysed significant research and development investments across the logistics industry, with competitors rushing to develop similar spatial reasoning capabilities for their own automated systems. The technology has established new benchmarks for warehouse automation performance and demonstrated the commercial viability of advanced AI navigation systems in industrial environments. Industry analysts predict that spatial reasoning will become a standard requirement for next-generation warehouse robots. ??

Planned enhancements to the ViLaSR Robots include expanded manipulation capabilities, allowing them to handle a broader range of package sizes and shapes with greater dexterity. Future versions are expected to incorporate advanced materials handling techniques, collaborative lifting capabilities for heavy items, and enhanced communication protocols for improved human-robot interaction. These developments will further expand the robots' operational versatility. ??

The spatial reasoning technology is being adapted for deployment in other Amazon facilities beyond traditional warehouses, including sortation centres, delivery stations, and even retail locations. The Amazon ViLaSR Warehouse Robots have proven that advanced AI navigation can be successfully scaled across diverse operational environments, opening new possibilities for automation in various sectors of the logistics ecosystem. ??

Research partnerships with leading universities and technology companies are advancing the fundamental science behind spatial reasoning AI, with potential applications extending beyond logistics into healthcare, manufacturing, and service robotics. The innovations developed for ViLaSR Robots are contributing to broader advances in autonomous systems and artificial intelligence. ??

Environmental impact considerations are driving development of more sustainable versions of the technology, with focus on renewable energy integration, recyclable materials, and carbon-neutral operations. Future Amazon ViLaSR Warehouse Robots are expected to contribute to Amazon's broader sustainability goals whilst maintaining operational excellence. ??

Economic and Strategic Implications

The economic impact of Amazon ViLaSR Warehouse Robots extends far beyond operational cost savings, creating strategic advantages that strengthen Amazon's competitive position in global e-commerce markets. The technology has enabled Amazon to process higher order volumes with greater efficiency, supporting the company's rapid growth whilst maintaining service quality standards. Investment analysts estimate that the spatial reasoning technology contributes significantly to Amazon's operational margin improvements. ??

Labour market implications have been carefully managed through retraining programmes that transition warehouse workers into higher-skilled roles focused on robot supervision, maintenance, and quality control. The ViLaSR Robots have created new job categories whilst eliminating repetitive manual tasks, demonstrating how advanced automation can enhance rather than simply replace human capabilities. ??

Supply chain resilience has been strengthened through the robots' ability to maintain operations during peak demand periods, labour shortages, and other disruptions. The Amazon ViLaSR Warehouse Robots provide operational flexibility that helps Amazon meet customer commitments even under challenging circumstances, contributing to brand reliability and customer loyalty. ???

Technology licensing opportunities have emerged as other companies seek to implement similar spatial reasoning capabilities in their own operations. Amazon's investment in ViLaSR Robots has created intellectual property assets that could generate additional revenue streams through licensing agreements and technology partnerships. ??

The competitive advantages created by spatial reasoning technology are driving industry-wide innovation, with significant implications for global logistics standards and operational best practices. The Amazon ViLaSR Warehouse Robots have established new performance benchmarks that are influencing automation strategies across the entire supply chain industry. ??

The Amazon ViLaSR Warehouse Robots represent a transformative breakthrough in logistics automation, combining advanced spatial reasoning AI with practical warehouse applications to create unprecedented operational capabilities. These innovative ViLaSR Robots have demonstrated that sophisticated artificial intelligence can be successfully deployed at scale in complex industrial environments, delivering measurable improvements in efficiency, safety, and cost-effectiveness. The technology's impact extends beyond Amazon's operations to influence industry standards, competitive dynamics, and the broader evolution of warehouse automation. As spatial reasoning capabilities continue to advance and expand into new applications, the Amazon ViLaSR Warehouse Robots will likely be remembered as a pivotal innovation that redefined the possibilities for intelligent automation in logistics and supply chain management. The success of this technology validates the potential for AI-driven solutions to address complex operational challenges whilst creating new opportunities for human-robot collaboration in industrial settings. ??