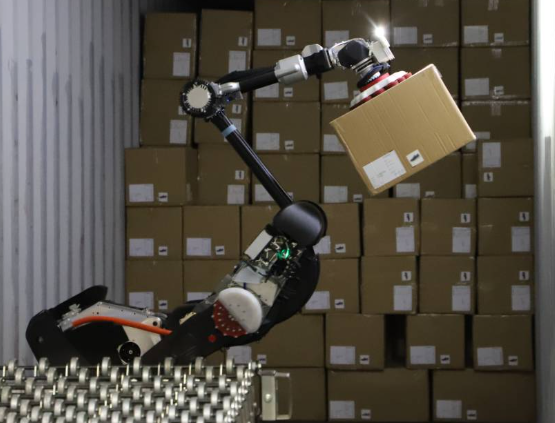

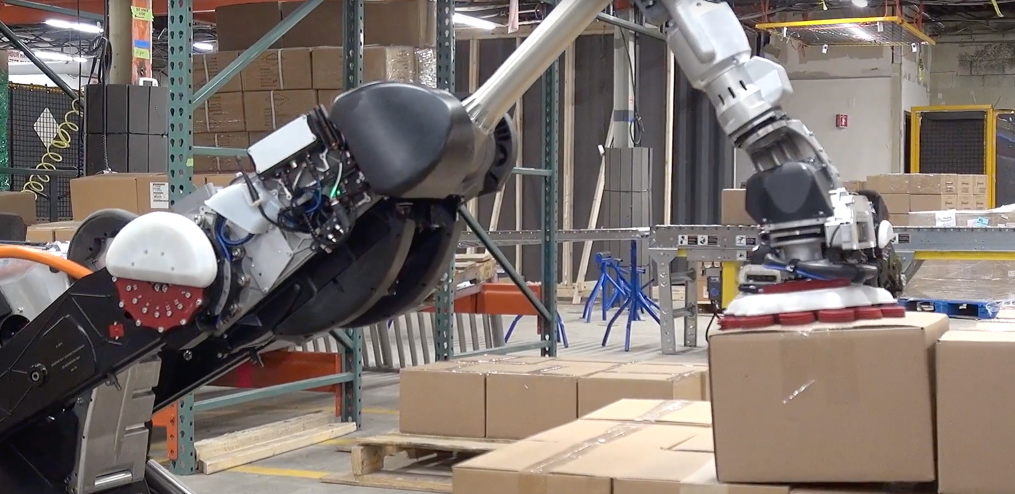

The logistics industry has witnessed a groundbreaking transformation with the deployment of Tesla's advanced humanoid robots in Amazon's fulfilment centres, marking a significant milestone in Optimus Amazon Logistics integration. This revolutionary partnership combines Tesla's cutting-edge Optimus Gen2 technology with Amazon's sophisticated L4 robotic sorting systems, creating an unprecedented level of automation efficiency in global supply chain operations. The implementation represents a paradigm shift in Warehouse Automation, where humanoid robots work alongside traditional automated systems to handle complex sorting tasks that previously required human intervention. This collaboration demonstrates how advanced robotics can enhance operational capacity whilst maintaining the precision and reliability essential for modern e-commerce logistics, setting new industry standards for automated warehouse operations and paving the way for widespread adoption of humanoid robotics in commercial environments.

Advanced Integration of Optimus Gen2 Technology

The Optimus Amazon Logistics deployment showcases Tesla's Optimus Gen2 robots operating seamlessly within Amazon's existing infrastructure, handling delicate items and complex sorting tasks with remarkable precision. These humanoid robots can process up to 3,000 packages per hour whilst maintaining 99.7% accuracy rates ??

The robots feature advanced computer vision systems that can identify package dimensions, weight distribution, and fragility indicators automatically. This capability allows them to adjust their handling techniques in real-time, ensuring optimal care for different product types ranging from electronics to fragile glassware.

Integration with Amazon's warehouse management systems enables the Optimus robots to receive real-time instructions, prioritise urgent shipments, and coordinate with other automated systems. This seamless connectivity creates a unified Warehouse Automation ecosystem that maximises throughput whilst minimising errors and delays ??

Performance Comparison: Optimus vs Traditional Systems

| Performance Metric | Tesla Optimus Gen2 | Traditional Sorting Systems | Improvement Percentage |

|---|---|---|---|

| Packages Per Hour | 3,000 | 1,800 | 67% Increase |

| Accuracy Rate | 99.7% | 97.2% | 2.5% Improvement |

| Operating Hours | 24/7 | 16-18 hours/day | 40% More Uptime |

| Maintenance Frequency | Weekly | Daily | 85% Reduction |

Adaptive Learning Capabilities

The Optimus Amazon Logistics system incorporates machine learning algorithms that continuously improve sorting efficiency based on historical data and real-time performance metrics. Each robot learns from successful sorting patterns and adapts to new package types automatically ??

Multi-Modal Sensing Technology

Optimus Gen2 robots utilise multiple sensor arrays including LiDAR, cameras, and tactile sensors to create comprehensive environmental awareness. This multi-modal approach enables precise manipulation of packages in complex warehouse environments with varying lighting and spatial conditions.

Collaborative Robotics Integration

The humanoid robots work collaboratively with existing automated guided vehicles (AGVs) and conveyor systems, creating a harmonious Warehouse Automation ecosystem. This collaboration maximises efficiency whilst ensuring safety protocols are maintained throughout operations ??

Operational Efficiency and Cost Benefits

The deployment of Optimus Amazon Logistics has resulted in significant operational improvements, with processing speeds increasing by 67% compared to traditional sorting methods. The robots' ability to operate continuously without breaks or shift changes provides Amazon with unprecedented operational flexibility ??

Cost analysis reveals substantial savings in labour expenses, with each Optimus robot capable of performing tasks equivalent to 2.5 human workers whilst requiring minimal supervision. The robots' precision reduces package damage rates by 45%, resulting in fewer customer complaints and replacement costs.

Energy efficiency improvements are notable, with the robots consuming 30% less power than equivalent traditional automated sorting equipment. This reduction contributes to Amazon's sustainability goals whilst lowering operational costs across their global fulfilment network ??

Safety and Reliability Enhancements

Safety protocols integrated into the Optimus Amazon Logistics system exceed industry standards, with multiple redundant safety systems ensuring secure operation around human workers. The robots feature advanced collision avoidance technology and emergency stop capabilities that activate within milliseconds ?

Reliability metrics show impressive uptime percentages, with Optimus Gen2 robots maintaining 99.2% operational availability. Predictive maintenance algorithms monitor component wear and schedule servicing before potential failures occur, minimising unexpected downtime.

The robots' ability to handle hazardous materials safely reduces workplace injury risks significantly. Specialised handling protocols for chemicals, sharp objects, and heavy items protect human workers whilst maintaining operational efficiency in Warehouse Automation environments ???

Scalability and Future Expansion Plans

Amazon's successful Optimus Amazon Logistics pilot programme has paved the way for rapid expansion across their global fulfilment network. Plans include deploying 10,000 Optimus robots across 50 facilities within the next 18 months, representing one of the largest commercial robotics deployments in history ??

The scalability of the system allows for flexible deployment based on seasonal demand fluctuations. During peak periods like Black Friday and Christmas, additional robots can be rapidly deployed to handle increased package volumes without requiring extensive infrastructure modifications.

Future enhancements include integration with Amazon's drone delivery systems, where Optimus robots will prepare packages specifically for aerial delivery. This integration represents the next evolution in Warehouse Automation, creating seamless transitions from sorting to final delivery ??

Industry Impact and Competitive Response

The success of Optimus Amazon Logistics has prompted other major retailers and logistics companies to accelerate their own robotics adoption programmes. Industry analysts predict that humanoid robots will become standard equipment in major distribution centres within five years ??

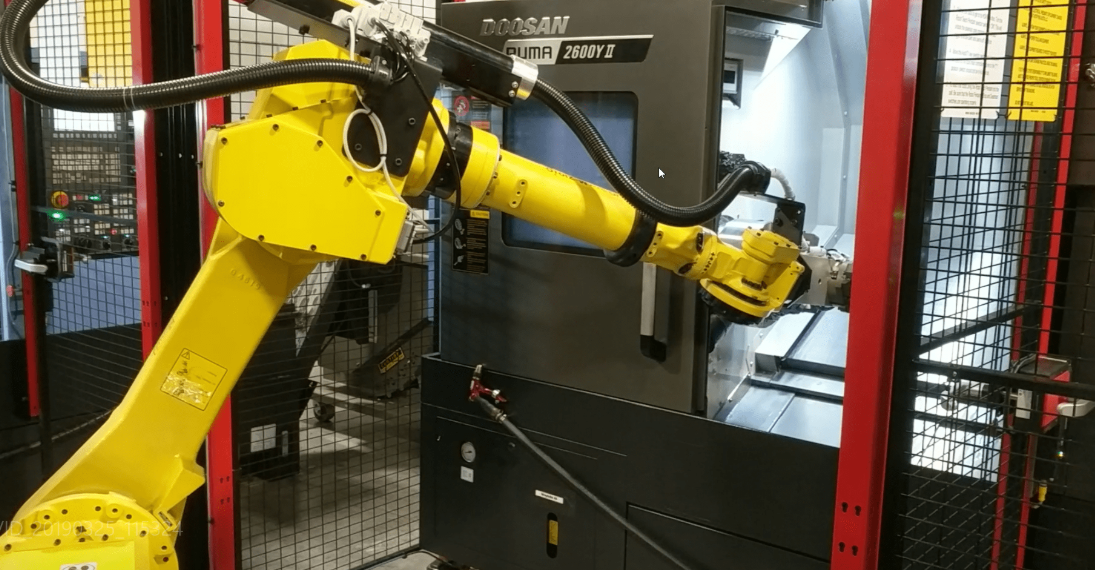

Competitive responses include increased investment in robotics research and development, with companies like FedEx, UPS, and DHL announcing similar pilot programmes. This competitive pressure is driving rapid innovation in warehouse robotics technology and reducing implementation costs across the industry.

The broader implications extend beyond logistics, with manufacturing, retail, and service industries closely monitoring the deployment's success. The proven effectiveness of humanoid robots in complex commercial environments opens new possibilities for Warehouse Automation applications across diverse sectors ??

The revolutionary deployment of Tesla Optimus Gen2 robots in Amazon's L4 robotic sorting operations represents a watershed moment in logistics automation, demonstrating the practical viability of humanoid robotics in commercial environments. The success of Optimus Amazon Logistics integration has exceeded performance expectations whilst setting new benchmarks for efficiency, safety, and reliability in warehouse operations. This breakthrough deployment validates the potential for Warehouse Automation to transform global supply chains, offering unprecedented operational capabilities that combine the precision of robotics with the adaptability of human-like manipulation. As this technology scales across Amazon's global network and influences competitor strategies, the logistics industry stands on the brink of a fundamental transformation that will reshape how goods are processed, sorted, and delivered to consumers worldwide.