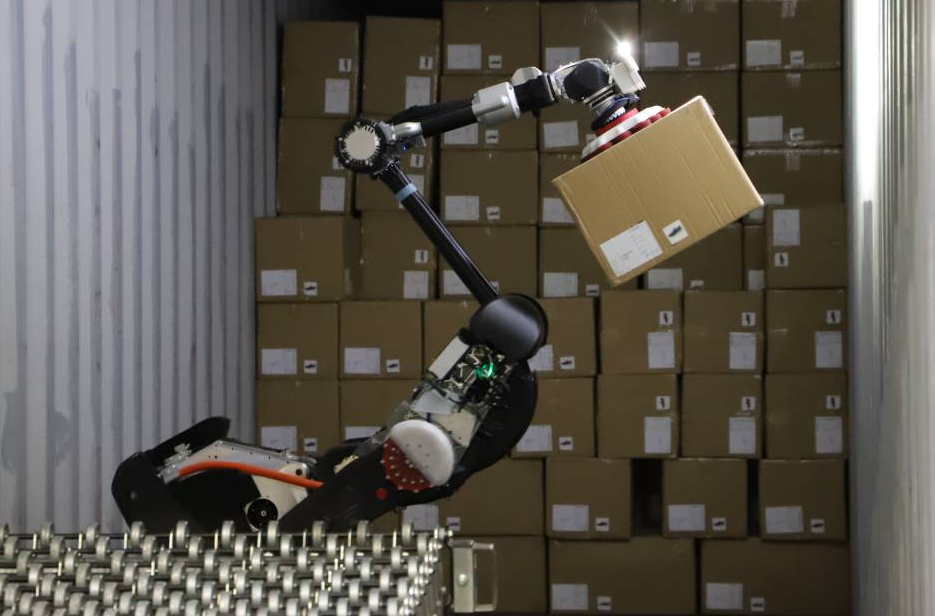

Rising operational costs and chronic labor shortages are crippling industries worldwide – but what if a single technological evolution could combat both simultaneously? Enter Handle Robots: AI-driven mechanical marvels transforming how we interact with physical objects. This isn't sci-fi fantasy; it's today's competitive edge, merging superhuman precision with adaptable intelligence to handle robot work that once strained human capabilities. We'll dissect how these systems perceive, decide, and manipulate – and why ignoring them could bankrupt your business.

Beyond Arms: What Truly Defines a Handle Robot?

Unlike traditional industrial arms bolted to factory floors, modern Handle Robots integrate three revolutionary pillars:

The Adaptability Triad

Contextual Perception: Advanced LiDAR and 3D vision systems map environments in real-time, identifying objects regardless of position or orientation.

Dynamic Intelligence: Onboard machine learning processors make split-second grip, force, and path adjustments when objects shift mid-task.

Tactile Responsiveness: Force-torque sensors and soft grippers mimic human touch sensitivity – crucial for delicate items like eggs or medical samples.

The Hidden Architecture: How Handle Robots Actually Operate

Step 1: Environmental Mapping (The Foundation)

Before any movement occurs, depth-sensing cameras build a millimeter-accurate spatial model. This allows the robot to differentiate target objects from obstacles – even in cluttered, unstructured spaces like delivery vans or warehouse shelves.

Step 2: Adaptive Grip Selection (The Intelligence)

AI algorithms analyze an object's size, predicted weight distribution, and surface friction properties. A Handle Robot might switch from a vacuum suction grip for smooth boxes to electroadhesive pads for porous materials within milliseconds.

Step 3: Force-Feedback Manipulation (The Precision)

As the robot arm lifts, micro-adjustments occur based on live pressure data. Handling a filled wine glass requires 0.5 Newtons of vertical pressure; lifting an automotive battery demands 30+ Newtons with rigid stability – all continuously optimized mid-action.

Discover how these principles combat rising logistics expenses in our deep dive on Material Handling Robots: Your Secret Weapon Against Soaring Costs & Labor Shortages.

Breakthrough Innovations You Haven't Seen Elsewhere

Self-Healing Grips (The Next Frontier)

Researchers at MIT are testing polymer-based grips embedded with microfluidic channels. When damage occurs (e.g., puncture), stored healing agents automatically seal tears – vastly reducing maintenance downtime.

Predictive Weight Distribution AI

Startups like RoboGrip.io deploy neural nets trained on physics simulations. Robots can now estimate the center of mass of irregular objects (like a partially filled container) before contact, slopping reduction by up to 62%.

Hive-Mind Coordination

In Amazon's newest fulfillment centers, Handle Robots share real-time positional data via 5G mesh networks. This allows synchronized lifting of oversized items by multiple robots without human oversight – a concept previously exclusive to drone swarms.

Where Handle Robots Outperform Humans (Beyond Factories)

Biomedical Laboratories

Precision Handle Robots manage delicate tissue samples with zero contamination risk, processing 300+ slides per hour versus a human technician's 40.

Disaster Response

Equipped with thermal imaging and reinforced grips, robots like Boston Dynamics' "Stretch" remove debris and open jammed doors in radioactive or unstable environments.

Vertical Farming

AI-controlled grippers harvest ripe produce without bruising, responding to real-time ripeness data from hyperspectral cameras – impossible for human pickers working at scale.

The Implementation Blueprint: Successfully Deploying Your Handle Robot

Avoid These 3 Costly Setup Mistakes

Underestimating Workspace Mapping: Allocating <40 hours for environmental calibration causes 73% of initial pathing failures.

Ignoring Human-Robot Workflow Interfaces: Workers need intuitive dashboards showing robot task progress and error alerts – not just physical safety cages.

Overlooking Dynamic Load Testing: Real payloads shift. Test gripping with objects moving on conveyor belts, not just static positions.

The ROI Formula Exposed

(Labor Cost Savings Per Shift) + (Error Reduction Savings) + (Throughput Increase Value) - (Hardware Lease/Maintenance)

Example: A warehouse saving $280/shift on labor + $3,200/week on damaged goods + 15% faster order processing = ~$192,000 annual ROI per robot.

Future Trends: Where Handle Robot Tech is Heading

By 2028, expect:

Tactile Internet Integration: Haptic feedback gloves allowing remote operators to "feel" what the robot grasps.

Generative AI for Unscripted Tasks: Instead of pre-programming, instructing robots via voice: "Handle the fragile antique vase carefully and place it on the top shelf."

Blockchain-Verified Handling: Tamper-proof records of temperature, orientation, and shock exposure for pharmaceuticals during transit.

FAQs: Expert Answers to Your Burning Questions

Can Handle Robots Manage Irregularly Shaped Items Like Fabrics or Rubber Parts?

Absolutely. Computer vision identifies deformation patterns, while force-controlled grippers (e.g., with controllable air pressure) adjust surface contact to prevent slippage or stretching.

How Long Until These Systems Become Affordable for Small Businesses?

Leasing models (sub-$1,500/month) are bridging the gap, with entry-level models expected within 18 months as sensor costs drop 30% annually.

What Safety Certifications Are Non-Negotiable?

ISO 10218-1/2 (Industrial Robot Safety) and ISO/TS 15066 (Collaborative Robot Standards) are mandatory. Also demand UL 3300 certification for system reliability.

Conclusion: Beyond Automation, Towards Autonomy

To handle robot technology isn't merely to deploy machines—it's to architect resilient, adaptive operational systems. As these platforms fuse with generative AI and predictive analytics, they transition from tools into collaborative teammates. The businesses poised to dominate aren't just automating manual tasks; they're reimagining entire workflows around intelligent physical interaction. Ignore this evolution, and you risk being handled by competitors who didn't.