In today's fast-paced industrial landscape, Material Handling Robot Applications are revolutionizing how businesses move, store, and manage goods. These intelligent machines do far more than just lift boxes - they're transforming warehouses, factories, and distribution centers with unprecedented efficiency and precision. From autonomous mobile robots navigating complex facilities to robotic arms performing delicate assembly tasks, the applications are as diverse as they are impactful. This comprehensive guide explores the cutting-edge uses of these robotic systems that are reshaping modern industry.

1. Warehouse Automation: The Backbone of Modern Logistics

The warehouse sector has become the primary battleground for Material Handling Robot Applications, with autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) leading the charge. These systems navigate complex warehouse environments using advanced sensors and AI algorithms, transporting goods between storage locations, packing stations, and loading docks with remarkable efficiency.

Modern robotic systems can handle everything from palletizing heavy loads to sorting small packages, working 24/7 without fatigue. They integrate seamlessly with warehouse management systems, enabling real-time inventory tracking and optimization. Companies implementing these solutions often see productivity increases of 200-300% while reducing operational costs by 30-50%.

One particularly transformative application is goods-to-person systems, where robots bring entire shelving units to human workers, eliminating the need for manual picking. This approach, combined with Material Handling Robots as secret weapons against labor shortages, is helping businesses overcome today's challenging labor market while meeting growing e-commerce demands.

2. Manufacturing Line Optimization

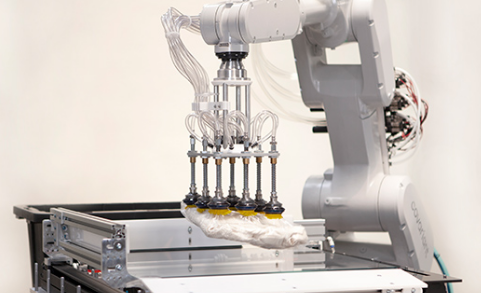

In manufacturing environments, Material Handling Robot Applications serve as the connective tissue between different production stages. Robotic arms equipped with specialized end-effectors can precisely transfer components between assembly stations, machine tools, and quality control points.

Collaborative robots (cobots) represent a particularly exciting development in this space. These machines work safely alongside human operators, handling repetitive or dangerous material transfer tasks while workers focus on higher-value activities. Cobots are increasingly used in automotive, electronics, and pharmaceutical manufacturing where precision and flexibility are paramount.

The integration of machine vision and AI has enabled robots to perform complex material handling tasks like part orientation, quality inspection, and even adaptive assembly. This technological leap is driving what many call the silent revolution in industrial automation, where smart material handling systems become intelligent partners in the manufacturing process.

3. Specialized Applications Across Industries

3.1 Food and Beverage Handling

In the food industry, hygienic material handling robots perform tasks like packing delicate produce, palletizing packaged goods, and even butchering meat. These systems are designed with food-grade materials and easy-clean surfaces to meet strict sanitation requirements.

3.2 Pharmaceutical and Laboratory Automation

Precision robotic systems handle sensitive materials in sterile environments, transporting medical supplies, sorting medications, and even assisting in laboratory testing procedures. Their accuracy and contamination-free operation make them invaluable in these critical applications.

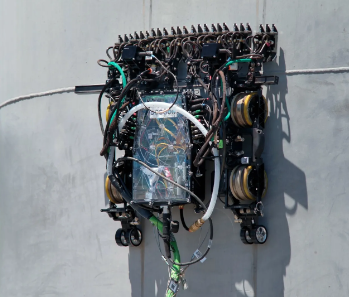

3.3 Construction and Heavy Industry

Robotic cranes, automated forklifts, and autonomous haul trucks are transforming material handling in construction sites and mining operations. These rugged systems can operate in hazardous environments while moving massive loads with millimeter precision.

4. Emerging Trends in Material Handling Robotics

The field of Material Handling Robot Applications continues to evolve rapidly, with several key trends shaping its future:

Edge computing is enabling real-time decision making at the robot level, reducing latency and improving responsiveness. 5G connectivity allows for seamless coordination between large fleets of robots across vast facilities. Advanced gripper technologies, including soft robotics and adaptive grasping systems, are expanding the range of materials robots can handle.

Perhaps most exciting is the integration of digital twin technology, where virtual simulations of material handling systems allow for continuous optimization before physical implementation. This approach significantly reduces deployment risks and accelerates ROI for automation projects.

5. ROI Considerations for Material Handling Automation

While the benefits of Material Handling Robot Applications are clear, businesses must carefully evaluate their automation investments. Key factors to consider include:

Implementation costs versus long-term labor savings, the flexibility to handle product variations and seasonal demand fluctuations, maintenance requirements and system uptime guarantees, and the potential for scalability as business needs evolve.

Most organizations find that the combination of increased throughput, reduced errors, and improved workplace safety delivers payback periods of 12-24 months, with ongoing benefits accumulating year after year.

Frequently Asked Questions

What types of materials can handling robots work with?

Modern material handling robots can work with virtually any physical material - from delicate glassware and food products to heavy metal components and construction materials. Advanced gripper technologies and sensor systems allow them to adapt to different shapes, weights, and material properties.

How do material handling robots improve workplace safety?

These robots eliminate many dangerous manual handling tasks that lead to workplace injuries. They can operate in hazardous environments (extreme temperatures, toxic atmospheres), handle heavy loads safely, and work at heights without risk. Collaborative robots further enhance safety with advanced sensors that detect and avoid human workers.

Can small businesses benefit from material handling robots?

Absolutely. The robotics market now offers scalable solutions for businesses of all sizes. Many providers offer robotics-as-a-service (RaaS) models with minimal upfront costs. Even small implementations in critical workflow bottlenecks can yield significant productivity gains and quality improvements.

The Future Is Here: Embracing Material Handling Robotics

As we've explored, Material Handling Robot Applications extend far beyond simple transportation tasks. These intelligent systems are becoming strategic assets that drive operational excellence across industries. From warehouses to factories, laboratories to construction sites, robots are handling materials with unprecedented efficiency, precision, and adaptability.

The ongoing advancements in AI, machine vision, and collaborative technologies promise even more transformative applications in the years ahead. Businesses that strategically implement these solutions today will gain significant competitive advantages in tomorrow's automated economy.

Whether you're looking to overcome labor challenges, improve workplace safety, or simply stay ahead of the automation curve, understanding and leveraging these robotic applications will be key to your operational success.