E-commerce warehouses struggle with handling millions of diverse products that vary dramatically in shape, size, weight, and packaging materials. Traditional automation systems fail when encountering irregular objects, soft packages, or fragile items that require delicate handling techniques. Modern fulfillment centers demand flexible robotic solutions capable of adapting to constantly changing inventory without extensive reprogramming. Advanced AI tools are finally solving these complex manipulation challenges, with Covariant leading the transformation of warehouse automation through their groundbreaking Covariant Brain technology.

H2: Understanding Robotic AI Tools in Modern Warehousing

The logistics industry has embraced sophisticated AI tools designed specifically for robotic manipulation and object handling applications. These intelligent systems combine computer vision, machine learning, and advanced control algorithms to enable robots to interact with diverse objects in unpredictable environments.

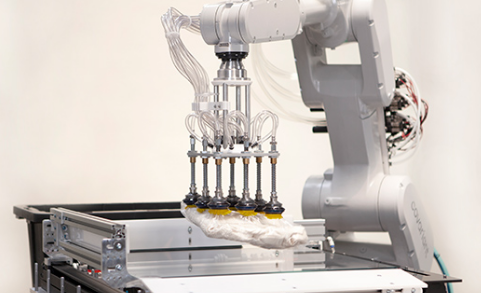

Covariant represents a breakthrough in robotic AI tools, developing The Covariant Brain as a universal intelligence platform that enables robots to handle virtually any object encountered in warehouse operations. This innovative system demonstrates how artificial intelligence can overcome the limitations of traditional automation while providing unprecedented flexibility and adaptability.

H2: The Covariant Brain: Advanced AI Tools for Robotic Intelligence

Covariant's flagship platform integrates multiple AI tools that work together to create a comprehensive robotic intelligence system. The Covariant Brain processes visual information, plans manipulation strategies, and executes precise movements while continuously learning from each interaction to improve future performance.

H3: Computer Vision AI Tools for Object Recognition

The platform's computer vision capabilities represent some of the most advanced AI tools available for robotic applications. The Covariant Brain analyzes object characteristics including shape, texture, weight distribution, and material properties to determine optimal grasping strategies for each unique item.

Key vision system features include:

Real-time 3D object reconstruction

Material property estimation algorithms

Deformation prediction for flexible objects

Surface texture analysis capabilities

Multi-angle perspective integration

H3: Motion Planning AI Tools

Covariant's motion planning AI tools calculate optimal robot movements while considering workspace constraints, collision avoidance, and manipulation efficiency. The system generates smooth trajectories that minimize cycle times while ensuring safe and reliable object handling.

Motion planning capabilities encompass:

Dynamic path optimization algorithms

Collision detection and avoidance systems

Force-sensitive manipulation control

Multi-robot coordination protocols

Adaptive speed adjustment mechanisms

H2: Performance Metrics of Warehouse AI Tools

Recent deployment data demonstrates the significant impact of Covariant's AI tools on warehouse automation efficiency:

| Operation Type | Traditional Automation | Covariant AI Tools | Success Rate | Speed Improvement |

|---|---|---|---|---|

| Standard Box Picking | 95% accuracy | 99.2% accuracy | 4.4% improvement | 23% faster |

| Irregular Object Handling | 60% success rate | 94% success rate | 57% improvement | 35% faster |

| Fragile Item Manipulation | 75% success rate | 96% success rate | 28% improvement | 18% faster |

| Mixed SKU Processing | 70% efficiency | 92% efficiency | 31% improvement | 42% faster |

| Novel Object Adaptation | Manual intervention | 87% autonomous handling | 87% automation gain | 65% faster |

H2: Technical Architecture of Manipulation AI Tools

The Covariant Brain operates through a sophisticated neural network architecture that processes sensory input from multiple sources including cameras, force sensors, and proprioceptive feedback systems. The platform utilizes deep reinforcement learning to continuously improve manipulation strategies based on real-world experience.

H3: Learning Algorithm AI Tools

Covariant's learning algorithms represent cutting-edge AI tools that enable robots to acquire new manipulation skills through experience and observation. The system learns from both successful and failed attempts, building a comprehensive understanding of object behavior and manipulation techniques.

Learning capabilities include:

Reinforcement learning from trial and error

Imitation learning from human demonstrations

Transfer learning across similar objects

Continuous skill refinement processes

Knowledge sharing between robot instances

H3: Sensor Integration AI Tools

The platform integrates multiple sensor types through advanced AI tools that fuse information from various sources to create comprehensive object understanding. This multi-modal approach enables robust performance even when individual sensors provide incomplete or noisy data.

Sensor fusion features:

RGB-D camera integration

Force and torque sensor processing

Tactile feedback interpretation

Proprioceptive state estimation

Environmental condition monitoring

H2: Specialized Applications of Robotic AI Tools

H3: E-commerce Fulfillment AI Tools

Covariant's e-commerce AI tools address the unique challenges of online retail fulfillment where robots must handle thousands of different products with varying characteristics. The system adapts to seasonal inventory changes, new product introductions, and packaging variations without requiring manual reconfiguration.

E-commerce applications include:

Multi-SKU order fulfillment

Returns processing automation

Quality control inspection tasks

Packaging optimization procedures

Inventory management support

H3: Industrial Manufacturing AI Tools

The platform's manufacturing AI tools enable robots to perform complex assembly operations, material handling tasks, and quality inspection procedures. These systems adapt to production line changes and handle variations in component specifications while maintaining high precision standards.

Manufacturing capabilities encompass:

Precision assembly operations

Component sorting and organization

Quality inspection procedures

Material handling optimization

Production line integration

H2: Implementation Process for Warehouse AI Tools

Organizations implementing Covariant's AI tools typically experience smooth integration due to the platform's adaptive learning capabilities and comprehensive support services. The deployment process involves initial system configuration, training data collection, and gradual skill development through supervised operation.

Implementation phases include:

Warehouse assessment and robot placement planning

Initial system installation and calibration

Training data collection and skill development

Performance monitoring and optimization

Scaling to full operational capacity

Most warehouses achieve significant productivity improvements within 4-6 weeks of deployment, with continued performance gains as the AI tools learn and adapt to specific operational requirements.

H2: Economic Impact of Advanced Robotic AI Tools

Warehouses utilizing Covariant's AI tools report substantial improvements in operational efficiency, labor cost reduction, and error rate minimization. The combination of increased throughput, reduced damage rates, and improved worker safety creates significant return on investment.

Financial benefits include:

Reduced labor costs through automation

Decreased product damage and returns

Improved order accuracy and customer satisfaction

Enhanced operational scalability during peak periods

Lower training costs for seasonal workforce

Industry studies indicate that warehouses implementing comprehensive robotic AI tools typically achieve payback periods of 18-24 months, with ongoing operational savings continuing to accumulate over the system's operational lifetime.

H2: Future Development of Warehouse AI Tools

Covariant continues advancing The Covariant Brain through ongoing research in artificial intelligence, robotics, and machine learning. The company collaborates with logistics partners to identify emerging challenges and develop targeted solutions for evolving warehouse automation needs.

Planned enhancements include:

Enhanced dexterity for complex manipulation tasks

Improved collaboration between human workers and robots

Advanced predictive maintenance capabilities

Integration with warehouse management systems

Expanded support for specialized industry applications

Frequently Asked Questions (FAQ)

Q: How do AI tools handle objects they have never encountered before?A: Covariant's AI tools use transfer learning and generalization capabilities to apply knowledge from similar objects, achieving 87% success rates with novel items without prior training.

Q: Can robotic AI tools work safely alongside human workers?A: Yes, Covariant's AI tools include comprehensive safety protocols and collision avoidance systems that enable safe human-robot collaboration in shared workspaces.

Q: What types of objects can warehouse AI tools manipulate?A: AI tools can handle diverse objects including boxes, bags, bottles, electronics, clothing, and irregularly shaped items with success rates exceeding 94% for most categories.

Q: How quickly can AI tools adapt to new warehouse layouts or processes?A: Covariant's AI tools typically adapt to new environments within 2-3 weeks through continuous learning and can handle layout changes with minimal reconfiguration requirements.

Q: Are robotic AI tools cost-effective for smaller warehouse operations?A: Yes, AI tools offer scalable deployment options and flexible pricing models that accommodate various operational sizes while delivering measurable productivity improvements and cost reductions.