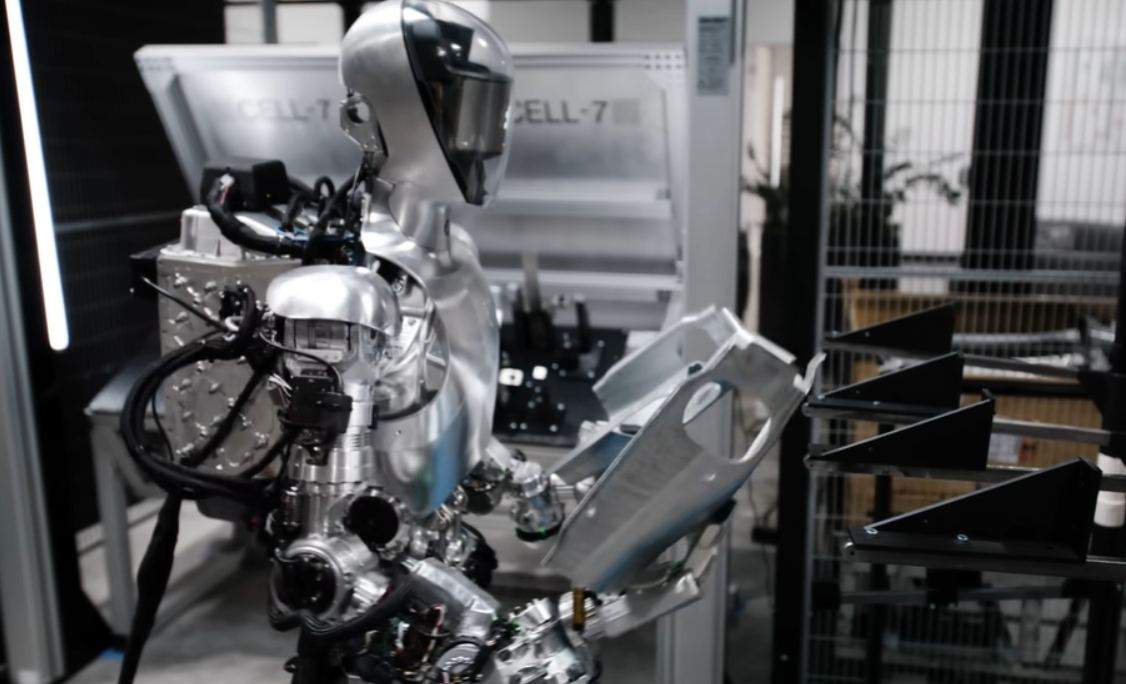

Imagine walking through a BMW factory where sparks dance like precision fireworks, massive robotic arms assemble chassis with ballet-like grace, and autonomous carriers glide silently between workstations – all orchestrated by artificial intelligence. This isn't science fiction; it's today's reality at BMW plants worldwide. For decades, BMW Robots have been the silent workforce behind the "Ultimate Driving Machine," evolving from basic automation to intelligent systems that blur the line between machine capability and human craftsmanship. Here's what makes BMW's robotic ecosystem the gold standard in automotive manufacturing.

What Exactly Are BMW Robots?

BMW Robots represent an integrated network of specialized automation systems deployed across BMW's global production facilities. Unlike standard industrial robots, these AI-enhanced systems perform tasks ranging from welding and painting to quality inspection and logistics with unprecedented precision. The German automaker currently operates over 5,000 robots across 30+ production sites, handling 95% of welding operations and 100% of paint applications in modern plants. What sets them apart is their cognitive layer: computer vision that detects micro-imperfections invisible to human eyes, machine learning algorithms that optimize movements in real-time, and neural networks that predict maintenance needs before failures occur.

Learn more about AI RobotThe Evolution Timeline: From Mechanics to Cognitive Systems

1980s - First-generation welding robots introduced, reducing chassis assembly from hours to minutes

2003 - Collaborative robots (cobots) debut in Spartanburg plant for door assembly

2018 - AI-powered vision systems implemented for paint defect detection

2021 - Self-learning logistics robots deployed at Dingolfing factory

2023 - Quantum computing integration for complex simulation testing

Future - Swarm robotics models under development for flexible production cells

Robotic Precision Meets Human Craftsmanship

Contrary to fears about automation replacing humans, BMW Robots work in concert with skilled technicians. At the Munich plant, robots handle 85% of welding tasks while humans perform final quality assessments. In Rolls-Royce production (BMW-owned), robots sand wood veneers before master craftsmen apply finishing touches. This synergy achieves a 0.002mm precision tolerance in engine assembly – 50x finer than human hair.

AI Brain: The Neural Network Behind the Machine

BMW's proprietary Industrial AI Core platform processes 1.7TB of sensor data per production line daily. Using deep learning algorithms, it enables:

Self-correcting welding paths based on thermal imaging

Predictive maintenance reducing downtime by 45%

Adaptive painting systems responding to humidity changes

Fault prediction with 92% accuracy across assembly lines

Inside BMW Robotics Jobs: The Human-AI Partnership

While headlines often suggest robots eliminate jobs, BMW's automation has actually created 12,000 new tech-focused positions since 2018. The modern BMW factory floor requires:

Robot Coordinators - Overseeing robotic teams with VR interfaces

AI Trainers - Teaching vision systems component recognition

Predictive Maintenance Specialists - Using IoT sensor analytics

Cobot Programmers - Developing human-robot interaction protocols

Staggering Efficiency: By the Numbers

BMW's $2.3 billion robotics investment yields quantifiable impacts:

?? 37 seconds - Average task cycle time vs 8 minutes manually

?? 63% energy reduction through motion optimization algorithms

?? 99.998% assembly precision across 5 million annual vehicles

?? 18% material waste reduction via AI-guided cutting patterns

?? 140,000 process improvements suggested by AI systems in 2023 alone

Future Frontiers: Where BMW Robotics is Headed

BMW's robotics roadmap reveals three revolutionary developments:

1. Metaverse Integration - Digital twins of entire factories running in NVIDIA Omniverse for real-time optimization

2. Cognitive Swarm Robotics - Fleets of small mobile robots that collaboratively problem-solve on the fly

3. Emotion-Sensing Cobots - Systems using camera-based mood analysis to adjust working tempo with human partners

By 2030, BMW plans fully flexible "robot hotels" where automated systems can be quickly reconfigured for different models within hours rather than weeks.

FAQs: Your BMW Robotics Questions Answered

Can BMW Robots build an entire car without humans?

While current systems handle ~90% of physical assembly, final quality control, luxury detailing, and complex wiring still require human expertise. The Leipzig plant's most automated line still employs 1,000 technicians coordinating with robots.

How do BMW's robots compare to Tesla's automation?

Unlike Tesla's more experimental approach, BMW focuses on reliability over velocity. BMW robots complete tasks 15% slower but with 50% fewer errors. BMW also prioritizes human-robot collaboration, whereas Tesla aims for full automation.

What happens when robots malfunction during production?

BMW's AI Core initiates a three-layer response: First, adjacent robots compensate for the task (5% disruptions solved this way). Second, automated diagnostics reroute assemblies (solving 85% issues). Finally, human specialists receive augmented reality instructions pinpointing exact repair procedures.

Are BMW's industrial robots eco-friendly?

Next-gen models use 40% less energy than 2018 counterparts. Regenerative braking systems capture motion energy, with Dingolfing plant robots feeding 19MW back into the grid annually - enough to power 5,000 homes.