Step behind the curtain of Bavaria's best-kept secret: the BMW Robot Factory. This isn't your grandfather's assembly line - it's a 21st-century ballet where 1,200 robots perform synchronized car-building magic with micron precision, orchestrated by AI brainpower you've never seen before. Discover how BMW's robotic revolution is building luxury vehicles at Formula 1 speeds while answering the burning question: what happens when German engineering meets artificial intelligence on the factory floor?

The BMW Robot Factory: Reinventing Automotive Manufacturing

BMW's Dingolfing plant epitomizes the future of manufacturing, where robots complete 95% of body welding at speeds impossible for human hands. Unlike conventional factories, BMW Robot Factory installations feature:

Self-learning robotic arms improving precision by 0.5mm annually through AI feedback loops

Swarm robotics where 60+ machines coordinate without central control

Predictive maintenance systems reducing downtime to just 15 minutes monthly

This evolution represents an $800 million strategic investment in robotic infrastructure since 2017, transforming factories that were manual strongholds into AI-powered marvels.

The AI Architects Behind BMW's Robotic Revolution

At the heart of BMW's operations sit three proprietary AI platforms making robotic autonomy possible:

iFACTORY OS (Intelligent Factory Operating System): The central nervous system processing 1.7TB of production data daily across Munich, Spartanburg and Shenyang facilities. Its machine learning algorithms optimize workflow in real-time, dynamically rerouting tasks between robots based on system diagnostics.

VisionAI: Computer vision technology inspecting 12 million weld points daily with 0.01mm accuracy. This surpasses human QC capabilities by detecting microscopic imperfections invisible to the naked eye.

CobotMind: The revolutionary programming allowing humans to teach robots new tasks simply by physically guiding their arms. BMW technicians have deployed 147 new assembly routines in 2023 alone using this intuitive interface.

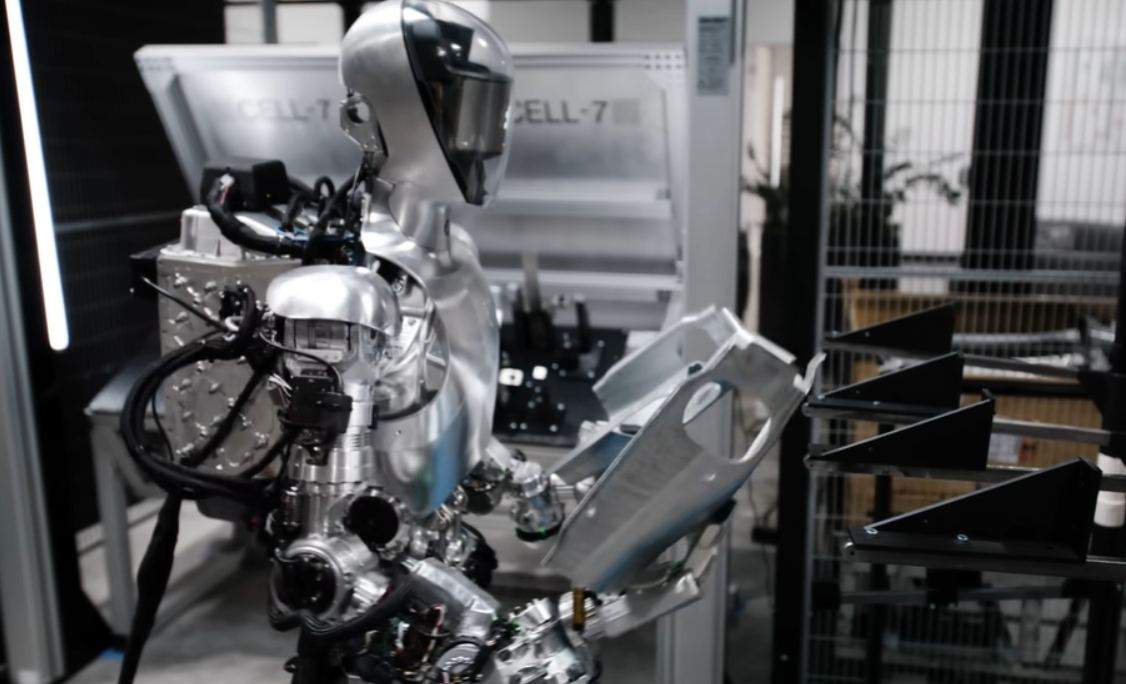

Learn more about AI RobotThe Invisible Assembly Line: A Day Inside a BMW Robot Factory

Walking through BMW's Leipzig facility reveals manufacturing reimagined:

0600: Autonomous transports deliver components to workstations with 22-second precision timing, synchronized by IoT sensors tracking 7,000+ assets

1000: Laser-guided KUKA robots install 1,214 M3 body panels with atmospheric plasma cleaning between each application

1400: Collaborative robots (cobots) assist technicians installing delicate iDrive systems using force-sensitive grippers

1700: AI predicts component replacement needs for 13 critical systems before humans detect wear

This technological symphony reduces production time per vehicle to just 16 hours (versus 30+ in traditional factories) while achieving BMW's famed quality standards.

Robots That Build Sustainability

BMW's robotic workforce contributes substantially to environmental goals:

Electric servo-drivers reduce energy consumption by 60% versus hydraulic systems

Precision application cuts paint usage by 150 tons annually across European plants

AI-optimized welding decreases steel waste by 92% since 2015 implementation

The automaker's "Industrial GreenTech" initiative leverages robotics to achieve a 60% carbon reduction per vehicle by 2030.

Tomorrow's BMW Robot Factory: What's Coming

BMW's robotics roadmap reveals disruptive innovations:

Quantum Computing Integration (2025): Pilot program using quantum algorithms to solve previously impossible production optimizations

Neuro-Robotics (2026): Brain-computer interfaces allowing technicians to control machinery via neural signals

Self-Replicating Cells (2028): Robots assembling other production robots on-site during maintenance windows

These advancements will enable mass customization at scale - factories capable of economically building 10,000 vehicles without identical configurations.

Behind The Scenes: Humans Who Master The Machines

Contrary to automation stereotypes, BMW robotics specialists enjoy 12% higher salaries than traditional auto technicians. The Munich plant employs 189 robot coordinators with expertise in:

Predictive maintenance programming

Machine learning optimization

Human-robot collaboration safety protocols

These positions require advanced qualifications including Industrial AI certification and neural network management training.

Inside BMW Robotics JobsBMW Robot Factory: Your Questions Answered

How many robots are in BMW factories?

BMW deploys over 8,500 industrial robots globally, with flagship plants like Dingolfing operating 1,200+ units. The density has increased 300% since 2010, enabling unprecedented production flexibility.

Do robots replace human workers at BMW?

BMW robotics actually created 3,200 new technical roles in five years. While automating dangerous/repetitive tasks, robots require highly skilled operators, programmers and maintenance specialists - positions with 35% lower turnover than traditional assembly roles.

Can BMW's robotic systems handle electric vehicles?

BMW's flexible manufacturing systems convert production lines between combustion, hybrid and electric models in under 26 minutes. Modular robots install both traditional engines and 600-volt EV battery packs using adaptive tooling systems monitored by thermal imaging AI.

How precise are BMW's welding robots?

BMW's laser-welding robots operate with 0.05mm accuracy - equivalent to splitting a human hair five times. This precision reduces chassis weight while increasing structural rigidity by 42% compared to conventional spot welding.

Inside BMW's Robot Factory: Where AI Builds Cars in 16 Hours! bmw-robot-factory-ai-automation Discover BMW's secret AI factories: 1,200 robots building cars with 0.05mm precision. See how robots create luxury vehicles in 16 hours & the future tech reinventing manufacturing! BMW Robot Factory, AI Manufacturing, Automotive Robotics