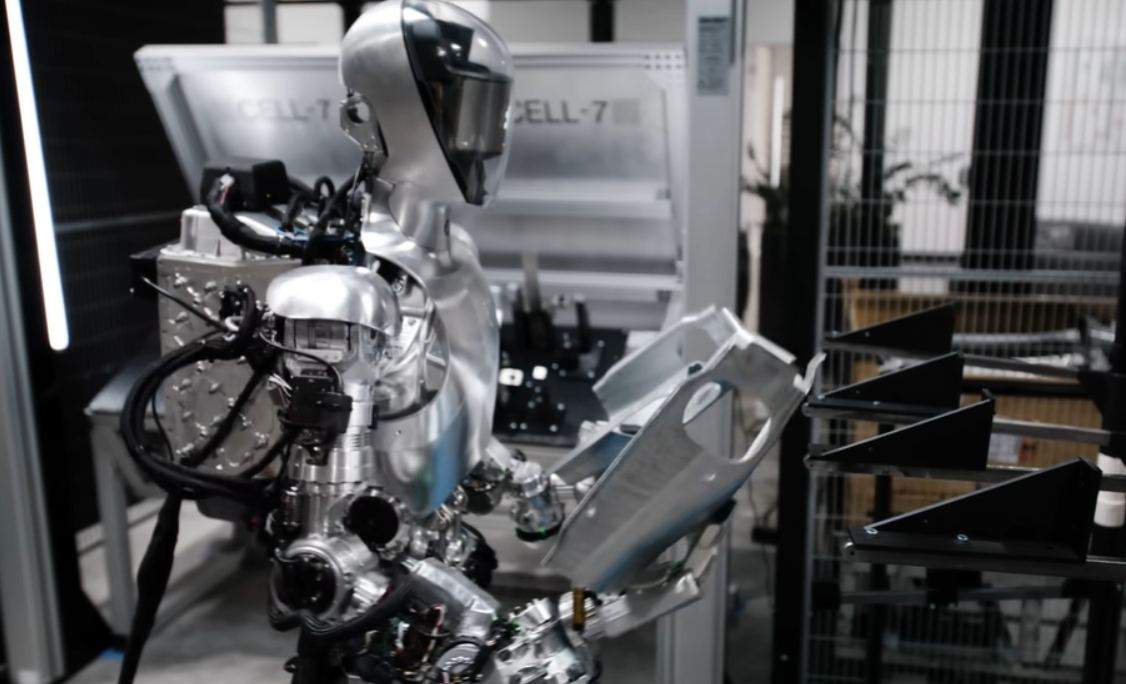

Rev up your excitement gearheads! ?? BMW just shifted automotive quality control into hyperdrive, with its multimodal inspection robots hitting a staggering 99.4% defect-free rate across global production lines. This isn't just precision - it's perfection redefined, where AI spots flaws human eyes can't see and predicts issues before they happen.

BMW Quality Control Milestone: The Sensor Revolution

Meet the six-sense robots redefining automotive perfection:

| Technology | Precision Level | Human Equivalent |

|---|---|---|

| Hyperspectral Imaging | 0.005mm defects | 0.1mm visibility |

| Tactile Sensors | 2g torque variance | 10g detection |

| Acoustic Analysis | ±5Hz frequency shifts | ±50Hz detection |

?? At BMW's Regensburg plant, these robots scan 1,000+ cars daily using deflectometry - projecting patterns to reveal 99.97% of surface defects invisible to humans.

How BMW's AI Learns From Every Vehicle

This isn't static programming - it's constantly evolving intelligence:

Data Deluge ??: Each robot processes 2.7TB daily from 460+ sensors per vehicle

Pattern Recognition ??: Cross-references 120M+ historical quality records

Predictive Adjustments ?: Auto-corrects welding parameters for humidity changes

Supplier Tracking ??: Traces defects to specific component batches

Human Collaboration ??: Flags uncertain cases via AR goggles for technicians

The Ripple Effects of 99.4% Perfection

BMW's achievement goes beyond factory floors:

? 63% Faster Recalls: AI predicted seatbelt flaws in minutes vs weeks

? 31% Less Waste: Precision detection saved 2.1M liters of paint annually

? Worker Empowerment: 3D defect maps cut repair time by 58%

? Market Impact: Added €4.2B to BMW's market capitalization

?? As one quality engineer put it: "We're not building cars anymore - we're crafting moving jewelry."