Imagine walking onto a BMW production line: not a scene of monotonous manual labor, but a mesmerizing ballet of advanced robots. Arms whir with uncanny precision, sensors feed constant data streams, and autonomous vehicles glide silently. This is modern automotive manufacturing, a powerhouse fueled by artificial intelligence and robotics. It's a common misconception that automation equals fewer jobs. In reality, for visionary companies like BMW, robotics isn't replacing humans; it's creating a surge in highly skilled, intellectually demanding, and incredibly rewarding new career paths. If you're captivated by the intersection of AI, cutting-edge machinery, and building premium vehicles, then understanding the world of BMW Robotics Jobs is your first step towards an exciting future at the forefront of industry.

Beyond the Assembly Line: The Ecosystem of BMW Robotics Jobs

BMW's integration of robotics extends far beyond just welding car bodies. It’s a complex ecosystem demanding diverse expertise. Forget the old image of factory work; these are tech-driven roles requiring problem-solving, programming prowess, and analytical thinking:

Robotics Engineer (Design/Development): These are the architects. They design robotic systems specifically for BMW's unique manufacturing challenges, focusing on precision, speed, safety, and integration with AI vision systems for quality control.

Robotics Technician / Maintenance Engineer: The vital caretakers. They ensure peak operational efficiency of existing robotic cells – performing diagnostics, preventive maintenance, complex repairs, and software updates. Demand here is particularly high.

Automation Engineer: They focus on the bigger picture, designing and refining entire automated *systems* that may involve multiple robots, conveyors, sensors, and control logic (PLCs). They ensure different robotic components communicate and work in seamless harmony.

AI & Machine Learning Specialist (Applied Robotics): A rapidly growing niche. These professionals develop and implement AI algorithms that make robots smarter – enabling predictive maintenance, adaptive grasping based on sensor feedback, anomaly detection in assembly processes, or optimizing robot paths in real-time.

Robot Programmer: Tasked with coding and debugging robot tasks. This goes beyond basic pathing; it involves integrating vision system commands, configuring force/torque sensing for delicate tasks like part insertion, and setting safety protocols.

Simulation Engineer: Before a single physical robot is deployed, simulation engineers build and test virtual models of robotic workcells and processes. This minimizes costly downtime and errors during implementation.

Curious about what these advanced BMW robot workers actually look like in action? See how precision meets power on the German production line: BMW Robot Workers: Precision Meets Power

Why Pursue a Career in BMW Robotics Jobs? The Compelling Advantages

Choosing a path in robotics at BMW isn't just about a job; it's about investing in a future-proof career with exceptional benefits:

Cutting-Edge Technology Access: Work with the most advanced industrial robots, AI systems, and automation technologies globally. BMW invests significantly to stay at the pinnacle.

Solving Complex Challenges: Every day presents new puzzles: optimizing cycle times, improving quality detection algorithms, integrating new models onto the line, or designing novel robotic applications.

Competitive Compensation & Stability: Roles in robotics, especially within the esteemed German automotive sector and a leader like BMW, command strong salaries and benefits packages, reflecting the high skill level required.

Future-Proof Skillset: Expertise in robotics and AI is increasingly transferable and in high demand across numerous industries beyond automotive, making your skills highly valuable.

Impact on Premium Mobility: Contribute directly to building some of the world's most desired and technologically advanced vehicles, knowing your work ensures BMW's reputation for quality.

Landing Your Dream Role: The Pathway to BMW Robotics Jobs

Securing a position in BMW's robotics division is competitive. Here’s what you need to know:

Core Educational Backgrounds: Typically, a Bachelor’s or Master’s degree in Robotics Engineering, Mechatronics, Mechanical Engineering, Electrical Engineering, Computer Science (with AI/robotics focus), or Control Systems Engineering.

Essential Technical Skills:

Robot Programming: Mastery of languages like KUKA KRL, ABB RAPID, Fanuc TP, and/or universal standards like ROS (Robot Operating System).

Industrial Automation: PLC programming (Siemens TIA Portal/S7, Allen-Bradley), HMI design, sensor integration (vision, force/torque, LIDAR), networking (Ethernet/IP, Profinet).

CAD/CAE: Proficiency in Siemens NX, CATIA, or similar for robot cell design and simulation software (e.g., Siemens Process Simulate, Visual Components).

AI/ML Foundations (Increasingly Important): Python, TensorFlow/PyTorch, data analysis, understanding ML concepts applicable to robotics (computer vision, predictive maintenance).

Systems Thinking & Problem Solving: Ability to troubleshoot complex electromechanical systems and optimize processes.

The "Soft Skills" Edge: Collaboration is paramount. You'll work with process engineers, production managers, and quality specialists. Communication, adaptability, and a commitment to continuous learning are non-negotiable. Proficiency in German is a significant asset for many roles based in Germany, though English is often the technical lingua franca.

Certifications Boost Credibility: Industry-recognized certifications (e.g., from robot manufacturers like KUKA, Fanuc, ABB; PLC certifications; ROS certifications) strongly validate your practical skills.

Key Insight: BMW is actively developing specialized internal apprenticeship and upskilling programs, such as the "BMW Certified Robotics Technician" pathway. This signals their commitment to building talent and opens routes beyond traditional university degrees for some maintenance and programming roles. Check BMW Group Careers regularly for these opportunities.

Dive deeper into the fascinating world of AI and robotics technology: Learn More About AI Robots

The Reality Check: Salaries & Expectations for BMW Robotics Jobs

Compensation varies based on location (Germany vs. other international plants), specific role, experience level, and qualifications. However, indicative salary ranges in Germany (converted to USD/EUR for reference) demonstrate the value placed on these skills:

| Role | Experience Level | Approx. Annual Salary (Germany) |

|---|---|---|

| Robotics Technician | Mid-Level (3-5 years) | $60,000 - $80,000 (€55,000 - €70,000) |

| Robot Programmer | Mid-Level (3-5 years) | $70,000 - $90,000 (€65,000 - €80,000) |

| Automation Engineer | Mid-Level (3-5 years) | $75,000 - $95,000 (€70,000 - €85,000) |

| Robotics Engineer (Design) | Senior (5-8 years) | $90,000 - $120,000+ (€80,000 - €105,000+) |

| AI/ML Specialist (Robotics) | Mid-Senior (3-8 years) | $95,000 - $130,000+ (€85,000 - €115,000+) |

*Note: Figures are indicative based on German automotive sector & engineering salary data (e.g., from VDI/VDE reports, Glassdoor, Levels.fyi) and represent gross base salary. BMW typically offers comprehensive benefits packages on top.

The Work Environment: Expect fast-paced, technically demanding settings – primarily BMW manufacturing plants (like Dingolfing, Munich, Spartanburg USA, Shenyang China) or technical development centers. Collaboration with international teams is common. Work may involve shift patterns depending on the role (especially maintenance).

Frequently Asked Questions About BMW Robotics Jobs

Q1: Do I need a PhD to work in robotics at BMW?

A: No, absolutely not. While R&D roles in new AI algorithm development might prefer PhDs, the vast majority of BMW Robotics Jobs – especially those focused on integration, programming, maintenance, and application engineering – are filled with candidates holding Bachelor's or Master's degrees in relevant engineering fields, often supplemented by significant practical experience and manufacturer certifications. BMW's internal apprenticeship programs also target the technician level.

Q2: Are English speakers disadvantaged for BMW Robotics Jobs based in Germany?

A: English is the primary language for technical communication within BMW's international teams and in many technical roles. Proficiency in English is essential. However, for roles requiring deep integration with German production teams, local suppliers, or regulatory bodies, proficiency in German becomes increasingly important and is often a formal requirement or a strong differentiator. For purely technical development or specialist roles within international teams, English might be sufficient, but learning German significantly enhances integration and long-term career prospects.

Q3: What's the biggest challenge facing BMW's robotics teams right now?

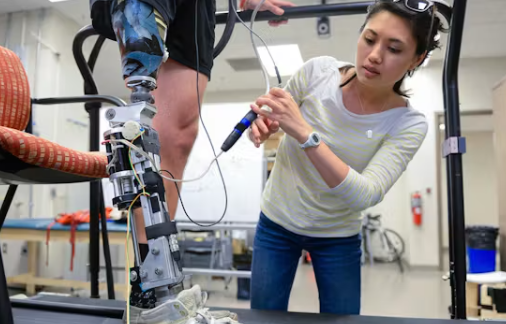

A: Beyond general integration and reliability challenges, a major focus is developing and implementing predictive maintenance solutions using AI. Analyzing vast sensor data streams (vibration, temperature, power consumption, error logs) from thousands of robots globally to predict failures *before* they cause costly production line stoppages is a critical frontier. Another key challenge is making collaborative robots (cobots) work more intuitively and safely alongside human workers for more complex, flexible tasks, requiring advances in AI perception and safety protocols.

Q4: Does BMW offer opportunities for international candidates, including relocation for BMW Robotics Jobs?

A: Yes, BMW does hire internationally for specialized and high-demand roles, including many robotics positions. However, the specifics heavily depend on:

The criticality of the role and difficulty finding local talent.

Your unique qualifications and experience level.

The legal work requirements for the specific country.

The Future of BMW Robotics Jobs: AI, Sustainability, and Flexibility

The trajectory is clear: deeper AI integration is the game-changer. Future BMW Robotics Jobs will increasingly demand skills in AI vision systems for defect detection, reinforcement learning for process optimization, and machine learning for predictive analytics driving maintenance efficiency. Sustainability pressures are also influencing robotics; roles focused on energy-efficient robot operation, lighter robot designs, and automation for electric vehicle-specific production processes are growing.

Furthermore, the rise of flexible manufacturing demands adaptable robotic solutions. Engineers skilled in designing and programming easily reconfigurable robotic workcells that can handle multiple car models on the same line with minimal downtime will be highly sought after. This is less about brute force automation and more about intelligent, adaptive robotic systems.

Ready to Step Into the Future?

BMW Robotics Jobs represent a unique convergence of prestige, cutting-edge technology, and tangible impact on the future of mobility. It's a field where human ingenuity programs, guides, and collaborates with robotic precision to create automotive excellence. If you possess the technical aptitude, the problem-solving drive, and a passion for innovation, BMW's robotics division offers a career path that is challenging, rewarding, and truly at the forefront of industrial AI. Explore the opportunities, hone the necessary skills, and position yourself to be part of building tomorrow's BMW, one robot at a time.