Picture this: a warehouse where pallets move with ballet-like precision, conveyor systems self-optimize in real-time, and production lines never stop for breaks – all orchestrated by intelligent machines that learn from every movement. This isn't sci-fi fantasy; it's today's reality powered by FANUC Material Handling Robots. As labor shortages cripple supply chains and consumers demand faster deliveries, these AI-driven systems have quietly become the backbone of modern logistics. In this deep dive, we'll reveal how FANUC's proprietary technologies are solving problems no human workforce ever could while slashing operational costs by 40-60%.

Why FANUC Material Handling Robots Are Redefining Industrial Automation

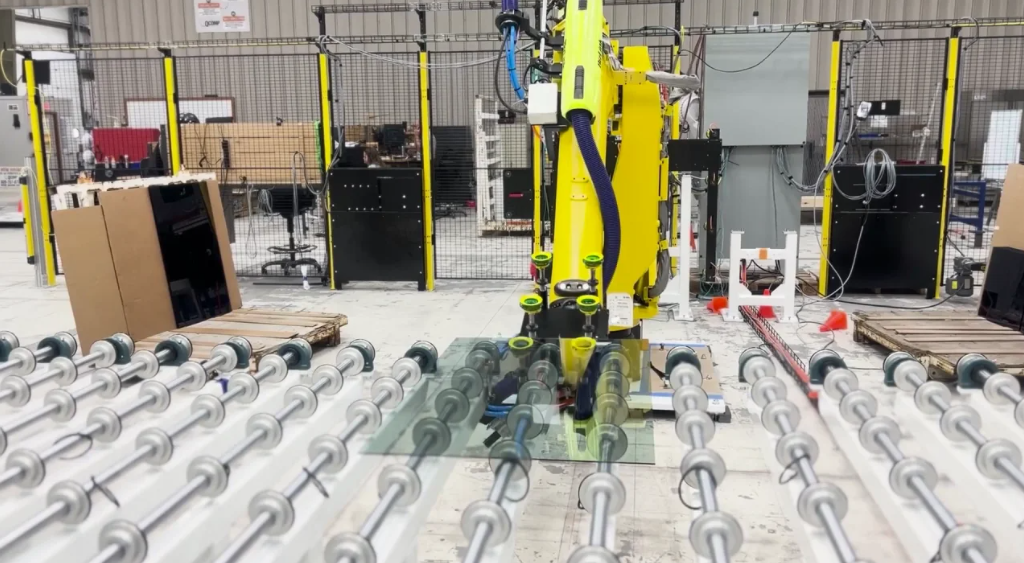

Unlike conventional automation, FANUC's systems leverage adaptive intelligence most competitors can't match. Their robots analyze friction coefficients of different materials, automatically adjusting gripper pressure when handling delicate electronics versus rugged automotive parts. Built-in machine learning algorithms process millions of motion data points to eliminate micro-stoppages that typically drain productivity.

The FANUC Material Handling Robots series includes several groundbreaking models:

M-20iD/25: The heavyweight champion capable of lifting 25kg payloads with 0.03mm repeatability

LR-10iD/10: Compact collaborative robot designed for tight spaces in electronics manufacturing

CRX-10iA: The first truly intelligent cobot that learns from human coworkers' movements

What sets these systems apart is their proprietary iRVision technology that enables real-time 3D part recognition without external sensors. This breakthrough alone reduces integration costs by 30% compared to traditional automation solutions.

The Hidden AI Capabilities in FANUC Material Handling Robots

While most manufacturers focus on mechanical specifications, FANUC's real innovation lies in its artificial intelligence stack. The FIELD system (FANUC Intelligent Edge Link and Drive) creates a neural network across multiple robots, allowing them to share learned behaviors and optimize collective performance.

Consider these advanced capabilities:

Predictive Maintenance AI: Analyzes motor currents and vibration patterns to predict bearing failures 200+ hours before they occur

Dynamic Path Planning: Uses reinforcement learning to continuously optimize movement trajectories, reducing cycle times by 5-15% monthly

Adaptive Gripping Intelligence: Computer vision combined with force feedback enables handling of undefined objects - a first in industrial robotics

These features explain why companies like Amazon and Toyota have quietly standardized on FANUC Material Handling Robots for their most demanding operations. The robots' ability to self-diagnose and improve over time creates compounding productivity gains that manual labor simply cannot match.

Real-World Applications: Where FANUC Material Handling Robots Excel

From pharmaceutical clean rooms to automotive assembly lines, these robots are transforming material handling across industries. Here are three groundbreaking implementations:

1. Pharmaceutical Packaging Revolution

A leading vaccine manufacturer deployed FANUC Material Handling Robots to handle delicate vials at speeds impossible for human workers. The robots' precision (±0.01mm) reduced breakage by 92% while increasing output by 300%. The cleanroom-compatible models also eliminated contamination risks inherent in manual handling.

2. Automotive Parts Sequencing

At a BMW plant in Germany, a fleet of 46 FANUC M-20iD robots orchestrates just-in-time delivery of parts to assembly stations. Using advanced material handling algorithms, the system reduced part misplacement incidents to zero while cutting logistics labor costs by 58%.

3. E-Commerce Fulfillment Breakthrough

An Asian e-commerce giant achieved 99.99% order accuracy using FANUC Material Handling Robots equipped with 3D vision. The robots dynamically adapt to package sizes from envelopes to large boxes, processing 1,200 items/hour with zero fatigue. This implementation inspired new approaches to automated logistics across the industry.

FAQs About FANUC Material Handling Robots

Q: How do FANUC robots compare to traditional material handling equipment like conveyors?

A: Unlike fixed conveyors, FANUC Material Handling Robots offer dynamic reconfigurability. Their AI-driven adaptability allows handling variable products without mechanical changes, reducing changeover time from hours to minutes.

Q: What safety features do these robots incorporate for human collaboration?

A: FANUC's CRX series features force-limited joints, skin-sensing technology, and predictive collision avoidance powered by 3D vision. These innovations allow safe operation alongside humans without traditional safety cages.

Q: How difficult is programming these advanced robots?

A: FANUC revolutionized programming with their TPP (Teach Pendant Programming) interface that uses augmented reality overlays. New operators can program basic material handling tasks in under 30 minutes, while complex AI behaviors leverage pre-trained neural networks.

The Future of FANUC Material Handling Robots

As we look toward 2025 and beyond, FANUC is pioneering several groundbreaking developments:

Quantum Computing Integration: Early tests show quantum algorithms could optimize robot paths 1,000x faster than classical computers

Haptic Feedback Networks: Robots sharing tactile learning across cloud platforms to instantly adapt to new materials

Self-Reconfiguring Swarms: Modular robots that autonomously combine/disassemble to handle changing material flows

These innovations promise to make FANUC Material Handling Robots even more indispensable in tomorrow's smart factories and warehouses. As supply chains face increasing volatility, the flexibility and intelligence of these systems will separate industry leaders from followers.

The silent revolution in material handling is here. FANUC Material Handling Robots represent not just incremental improvement, but a fundamental shift in how goods move through our economy. For businesses facing labor shortages, quality challenges, or unpredictable demand, these intelligent systems offer solutions that are simultaneously more capable and more adaptable than any human workforce could ever be. The question isn't whether to adopt this technology, but how quickly your operation can implement it before competitors gain an insurmountable advantage.