The Dawn of Automation: BMW's Robotics Revolution

Since the 1970s, BMW has been at the forefront of integrating robotics into automotive manufacturing, transforming how premium vehicles come to life. This intricate dance of steel and silicon represents one of manufacturing's greatest success stories – where human ingenuity meets mechanical perfection. The evolution of BMW Robotics demonstrates how industrial automation grew from simple mechanical arms to today's AI-powered systems working alongside human technicians.

Pioneers and Partnerships: Who Created BMW Robotics?

The Industrial Robotics Forefathers

While no single person "invented" BMW Robotics, several pioneers created the technological foundations BMW would later perfect:

George Devol (1912-2011): Patented the first industrial robot arm (Unimate) in 1954

Joseph Engelberger (1925-2015): "Father of Robotics" who commercialized Devol's invention

KUKA Robotics Founders (1898): The German company that became BMW's primary robotics partner

BMW Engineering Teams: Unknown innovators who first integrated robots into BMW plants starting in the 1970s

BMW first implemented robotics technology in 1973 at their Munich plant, utilizing KUKA robots primarily for spot welding. This partnership revolutionized automotive manufacturing and continues today, with BMW factories featuring thousands of KUKA robots working with micron-level precision.

BMW Robotics Timeline: Evolution of Excellence

| Year | Milestone | Impact |

|---|---|---|

| 1973 | First robot implementation (spot welding) | Reduced production time by 50% |

| 1990s | Precision assembly robots | Improved component fit accuracy by 30% |

| 2000s | Collaborative robots (cobots) | Enabled human-robot workflows improving safety |

| 2014 | AI vision systems | Reduced defects to 0.02% on critical systems |

| 2020 | Cloud-connected robotics | Enabled real-time manufacturing optimization |

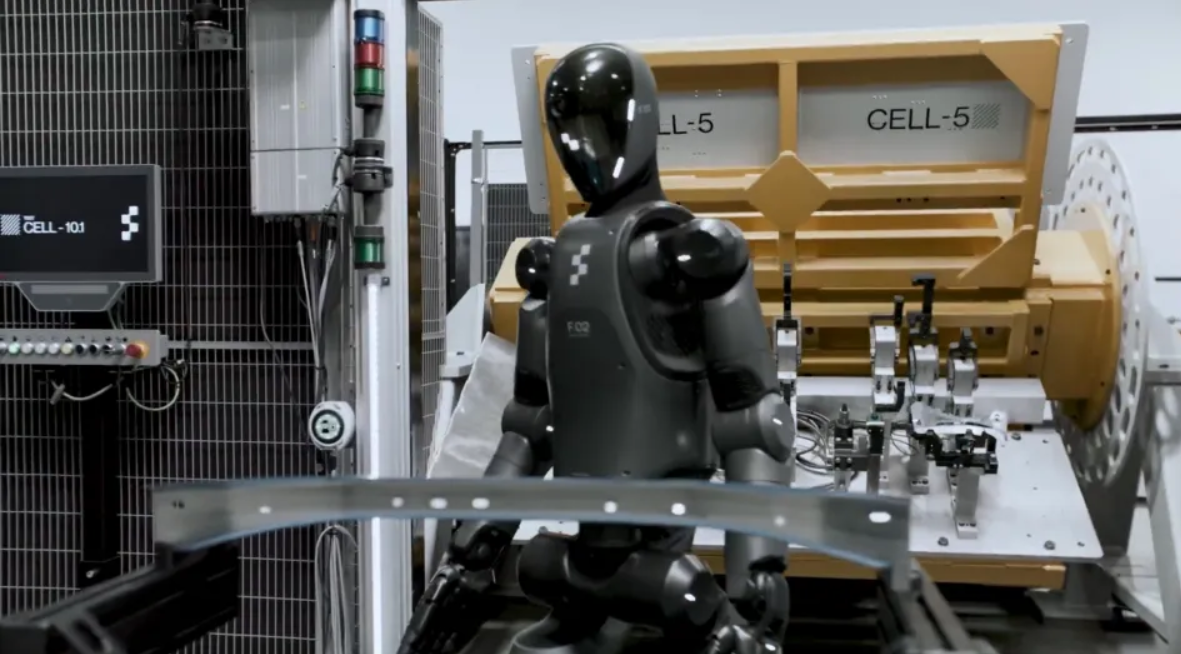

BMW Robotics Today: Intelligent Automation Ecosystem

Where Are BMW Robots Used?

Modern BMW Robotics represents a sophisticated integration of hardware and AI software. Their implementation spans:

Body Shop Operations

Over 800 welding robots work simultaneously on BMW X5 models

Laser braze-welding for flawless roof joints

Precise adhesive application with ±0.05mm accuracy

Paint Shop Mastery

Electrostatic paint robots achieving uniform coatings 8 microns thick

Self-calibrating systems that maintain perfect spray patterns

Color-matching algorithms guaranteeing consistency

Final Assembly

AI-guided collaborative robots installing delicate wiring harnesses

Machine vision verification systems checking 300+ critical points

Autonomous logistics robots delivering components

Quality Assurance

Ultrasonic testing robots detecting microscopic defects

Laser scanning stations creating full-vehicle digital twins

Machine learning systems predicting maintenance needs

The revolutionary approach BMW took wasn't just about installing robots, but creating an integrated Intelligent Assist Systems philosophy that enhances human capabilities rather than replacing them.

The BMW Robotics Advantage: Why Robots Build Better Ultimate Driving Machines

Precision Beyond Human Capability

BMW Robotics achieve:

Welding accuracy to 0.2 millimeters

24/7 consistent torque application on fasteners

Paint thickness variations under 3 microns

Repetitive actions with zero fatigue deviations

This technological consistency translates directly to the driving experience BMW owners feel. Panel gaps tighter than a human hand can achieve contribute to the characteristic solid "thunk" when closing a BMW door.

AI-Driven Continuous Improvement

Modern BMW Robotics platforms constantly evolve through:

Deep learning algorithms: Systems learn from millions of previous welds to refine techniques

Predictive analytics: Sensors anticipate equipment failures before they occur

Digital twinning: Virtual models simulate improvements before physical implementation

Adaptive processing: Systems self-adjust for variations in environmental conditions

The Plant Spartanburg facility processes >5 million production data points every day to feed these AI optimization loops.

Sustainability Through Automation

BMW Robotics significantly reduces:

Energy consumption (up to 25% less per vehicle)

Material waste (precision applications minimize paint and adhesive waste)

Carbon footprint (optimized logistics paths save thousands of transportation miles)

Safety incidents (eliminating humans from dangerous environments)

Behind the Scenes: BMW's Robotics Talent Ecosystem

– Dr. Petra Renz, Head of Automation at BMW Group

Inside BMW Robotics Jobs: Where AI & Automation Fuel Elite Careers

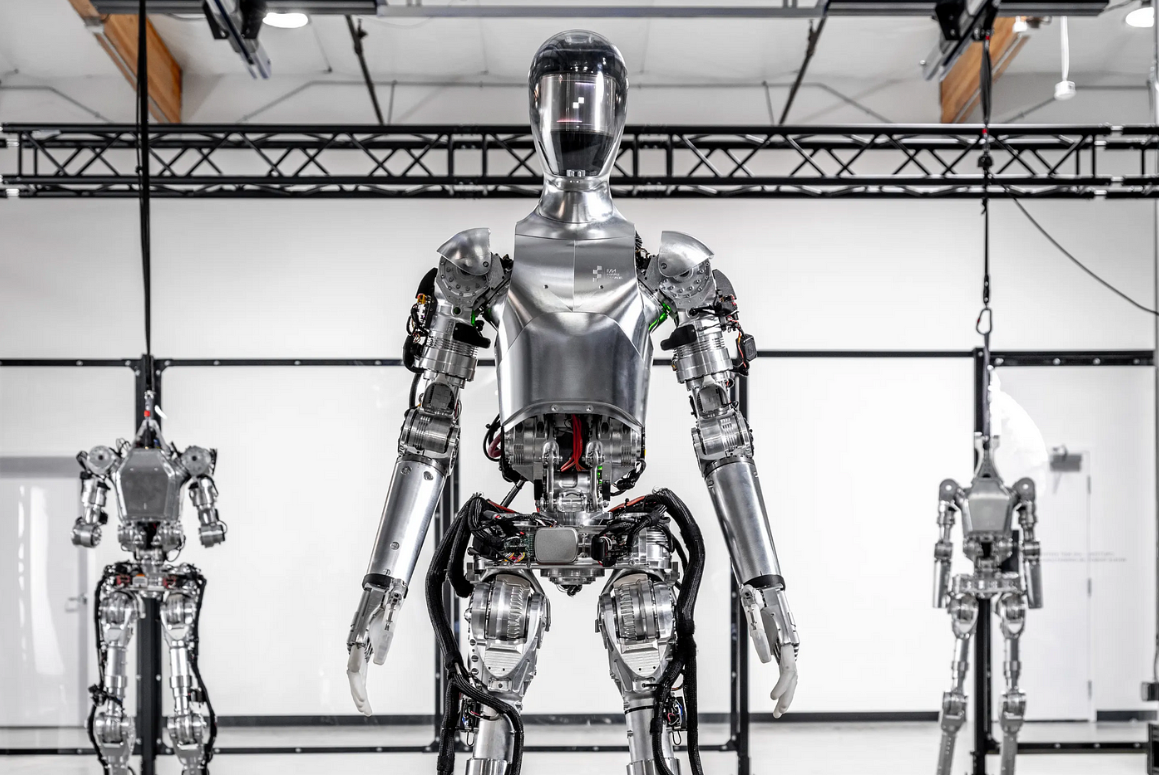

The Future of BMW Robotics: Where Are We Headed?

Next-Generation Robotics in Development

BMW is pioneering innovations that will transform automotive manufacturing:

1. Cognitive Robotics

Neurosymbolic AI systems that understand context like humans

Decision-making capabilities during unexpected production events

Self-optimizing workflows without human programming

2. Hyper-Collaborative Workspaces

Lightweight robotic exoskeletons multiplying worker strength

Mixed reality interfaces for human-robot communication

Emotion recognition systems ensuring optimal collaboration

3. Self-Organizing Production

Swarm robotics coordinating large-scale operations

Autonomous factories operating lights-out during peak demand

Flexible cell-based manufacturing instead of fixed assembly lines

These advancements will make the BMW Robotics platform 40% more efficient while reducing production costs and expanding customization capabilities beyond current limitations.

Frequently Asked Questions

Who actually invented the first robot BMW used?

BMW didn't invent industrial robotics but pioneered their automotive application. The first robots in BMW factories (1973) were KUKA Famulus models – the world's first electrically driven robots. These originated from KUKA's foundational work in Augsburg, Germany.

What percentage of BMW manufacturing is automated?

BMW plants average 90-95% automation in body shops, 75-80% in paint shops, and 10-20% in final assembly where human craftsmanship remains essential. The specific automation rate varies by model, with luxury models having higher automation levels.

Are BMW robots programmed differently for different models?

Yes, BMW Robotics use advanced flexible manufacturing systems. Within 18 minutes of a new vehicle entering a station:

Vision systems identify model specifications

Robots download customized programs

Tooling automatically reconfigures

Process parameters adjust (like welding temperatures)

This allows BMW plants to build different models simultaneously on the same line, enabling unprecedented customization while maintaining efficiency.

Conclusion: The Ongoing Evolution of BMW Robotics

The story of BMW Robotics isn't about a lone inventor but about continuous innovation across decades. From the first welding arms in 1970s Munich to today's AI-powered manufacturing network, BMW has constantly redefined what's possible in automotive automation. The company now stands at an inflection point where robotics aren't just tools but cognitive partners in manufacturing. As BMW prepares its plants for electrification, the role of advanced robotics will only grow more crucial.

The robots building today's BMWs increasingly learn from each new vehicle manufactured, meaning tomorrow's robotics platforms will emerge from yesterday's production. This virtuous circle of human ingenuity and machine intelligence continues to drive BMW's manufacturing excellence – ensuring the Ultimate Driving Machine will be built with even more precision tomorrow than it is today.