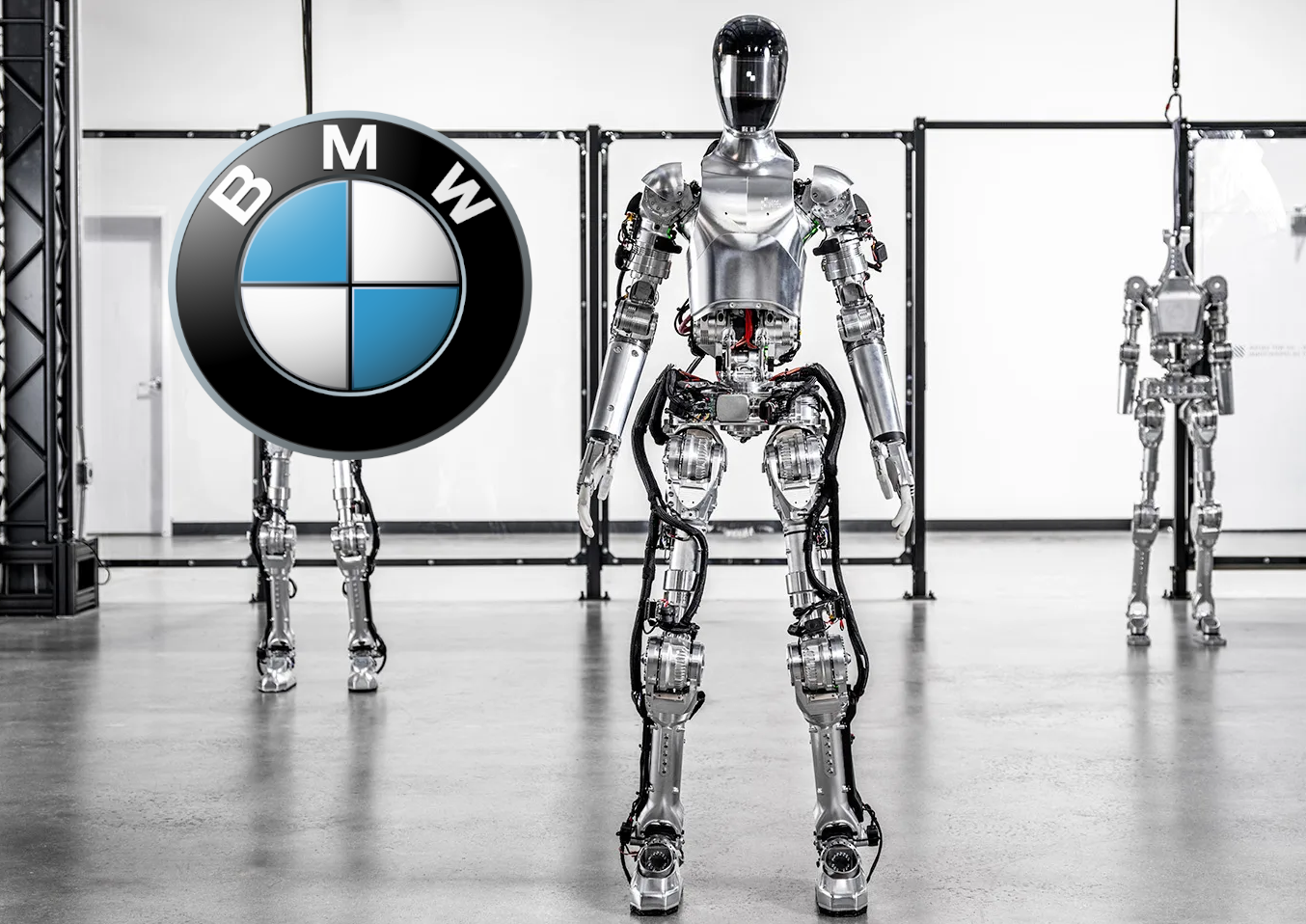

Imagine stepping onto the gleaming floor of a modern BMW factory. The unmistakable scent of new car components hangs in the air, but amidst the controlled hum of activity, you might notice some workers aren't human. Sleek, powerful arms execute complex welds with millimetric precision. Agile mobile platforms glide effortlessly, delivering parts exactly where and when they're needed. Vision systems tirelessly scan for flaws invisible to the naked eye. These aren't just machines; they're the next generation of the BMW workforce – sophisticated BMW Robot Workers collaborating seamlessly with human colleagues to forge the Ultimate Driving Machines. Forget visions of distant factories; BMW's intelligent automation revolution is happening now, meticulously engineered to uphold legendary German quality standards while pushing the boundaries of manufacturing efficiency. This is the future of carmaking, unfolding on the factory floor today.

Beyond Assembly Lines: The Diverse Ecosystem of BMW Robot Workers

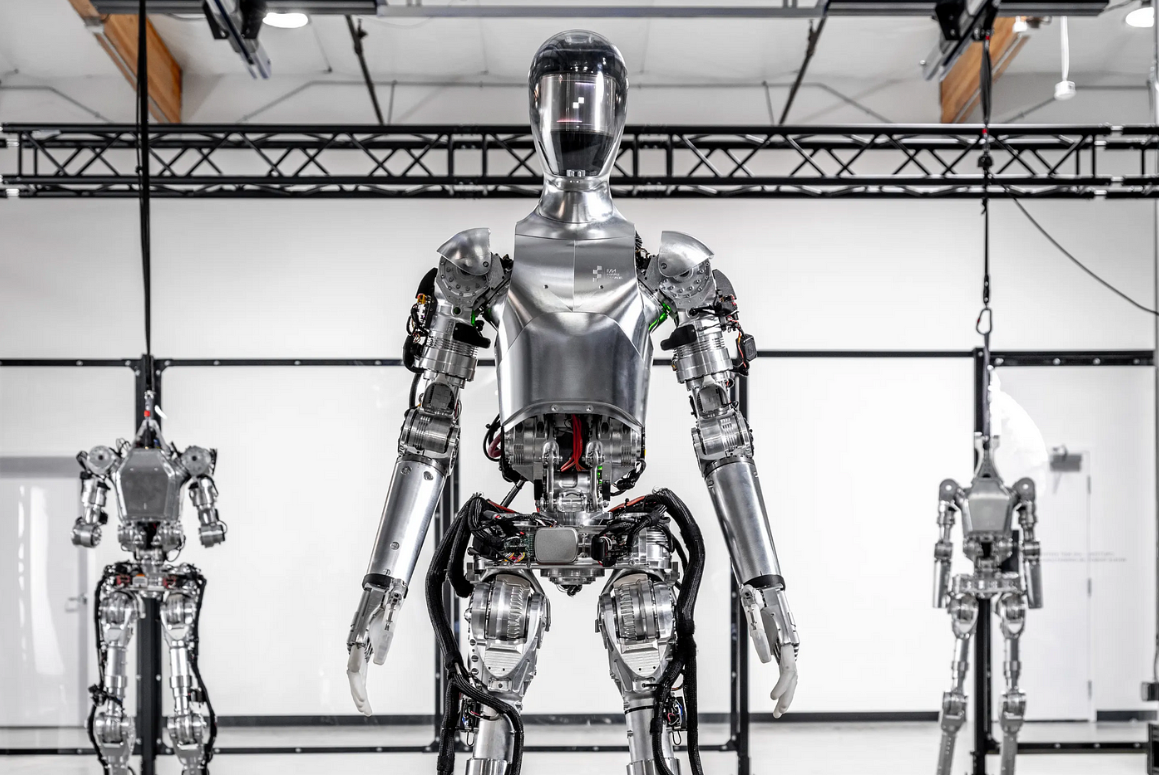

Gone are the days of robots confined to heavy lifting on static assembly lines. BMW employs a sophisticated orchestra of robotic technologies, each tailored for specific tasks, reflecting a strategic embrace of automation where it delivers the most value.

Industrial Robotic Arms: These are the backbone of body shop operations. Primarily from suppliers like KUKA and Fanuc, these powerful BMW Robot Workers perform thousands of spot welds per car body with unwavering accuracy and speed, ensuring structural integrity that meets BMW's rigorous crash test standards. Their application extends to painting booths, applying consistent, high-gloss finishes, and handling heavy components like engines and transmissions with precise placement.

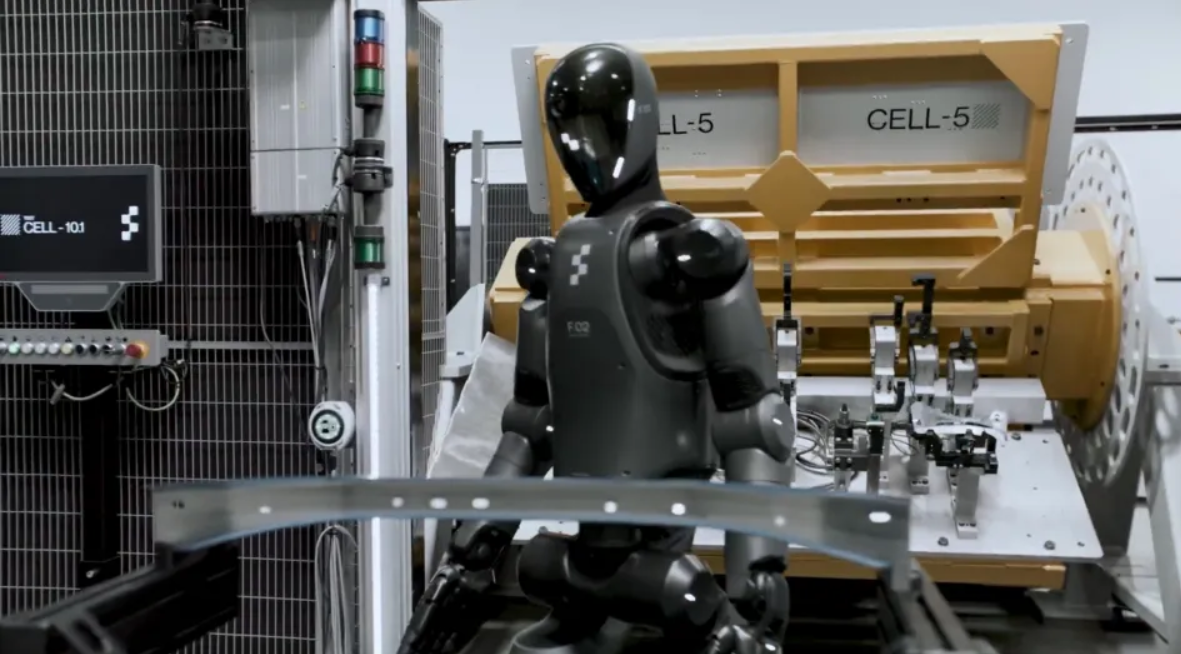

Collaborative Robots (Cobots): Designed for safe interaction, these nimble BMW Robot Workers work directly alongside humans without bulky safety cages. In Spartanburg, South Carolina, and Dingolfing, Germany, cobots handle tasks like applying sealant to doors, fitting interior components, or intricate wiring. They reduce ergonomic strain for human workers by taking over repetitive or uncomfortable motions, allowing humans to focus on complex assembly and quality assurance.

Learn more about AI RobotMobile Platforms & AGVs: Efficiency flows from logistics. Autonomous Guided Vehicles (AGVs) and more sophisticated Autonomous Mobile Robots (AMRs) are crucial BMW Robot Workers. They navigate factory floors autonomously using advanced sensors and mapping, delivering parts, components, and tooling precisely to the required station just-in-time. This eliminates wasted movement and optimizes workflow, as seen prominently in facilities like Regensburg.

Vision-Guided & AI-Powered Inspection Robots: Quality is paramount. BMW employs BMW Robot Workers equipped with high-resolution cameras and sophisticated AI-driven vision systems. These systems scan surfaces for micro-dents, scratches, paint flaws, or weld imperfections far surpassing human visual acuity. Some systems use machine learning, becoming more adept at spotting defects over time, ensuring only flawless vehicles proceed down the line.

Specialized Manipulators: Enter the "legless spiders." These unique, multi-axis manipulators at the BMW Group Plant in Dingolfing are specialized BMW Robot Workers. Operating overhead, they perform complex operations like fitting panoramic glass roofs with incredible dexterity and precision, navigating confined spaces within the car body where traditional robots cannot reach.

Why Robots? The Strategic Imperatives Driving BMW's Automation

BMW's commitment to integrating BMW Robot Workers isn't about replacing people wholesale; it's a calculated strategy addressing core manufacturing challenges in the premium automotive sector:

Uncompromising Quality & Consistency: Robots eliminate human error from repetitive tasks. Every weld is placed perfectly, every paint layer is applied uniformly, every component is torqued to exact specifications. This relentless consistency is essential for maintaining BMW's brand reputation for quality and reliability.

Enhancing Human Safety & Ergonomics: Automating hazardous tasks (welding sparks, heavy lifting, exposure to paint fumes, repetitive stress injuries) protects human workers. Cobots specifically take over ergonomically taxing roles, improving long-term worker well-being and reducing workplace injuries significantly.

Complexity & Customization: The demand for personalized vehicles (individual colors, trims, packages) is soaring. BMW Robot Workers offer the flexibility needed to manage this complexity. They can be quickly reprogrammed for different tasks or models, facilitating batch-size-one production without sacrificing speed or quality.

Operational Efficiency & Scalability: Robots operate tirelessly, 24/7 if needed. They accelerate cycle times and increase throughput without proportional increases in labour costs. Production lines can be scaled or reconfigured more rapidly using robotic systems, providing crucial flexibility in a volatile market.

Precision & Handling Delicacy: Paradoxically, robots handle delicate tasks (like fitting intricate trim or electrical connectors) with more consistent finesse than human hands, especially after hours of repetitive work. Their absolute precision is non-negotiable for modern vehicle electronics assembly.

Not Just Tools, Teammates: Humans + BMW Robot Workers

The narrative isn't humans versus robots, but humans with robots. BMW explicitly refers to its robots as "workers" – part of the team. Human skills evolve:

Robot Programming, Oversight & Maintenance: Highly skilled technicians and engineers design robot workflows, perform complex programming, conduct preventative maintenance, and troubleshoot sophisticated systems.

Data Analysis & Process Optimization: Humans interpret the vast data generated by BMW Robot Workers to identify inefficiencies, predict maintenance needs, and continuously improve processes.

Complex Assembly & Quality Validation: Tasks requiring dexterity, complex problem-solving, subjective judgment, and final quality sign-off remain firmly in human hands. Humans guide the process where flexibility and nuanced decision-making are critical.

Collaboration Interface: Workers manage the handoffs between automated and manual stations, ensuring seamless integration and stepping in when unpredictable situations arise.

The most successful BMW plants embody this synergy, where BMW Robot Workers handle the physically demanding, hazardous, or repetitive tasks with superhuman consistency, freeing human ingenuity for higher-value functions.

Challenges and the Road Ahead for BMW Robot Workers

Despite the success, integrating such advanced automation presents ongoing challenges:

Massive Capital Investment: Deploying a fleet of sophisticated BMW Robot Workers requires substantial upfront and ongoing investment (purchase, installation, integration, maintenance).

Complex Integration & Software: Ensuring diverse robotic systems communicate effectively (Machine-to-Machine, M2M) and integrate flawlessly into existing Manufacturing Execution Systems (MES) is complex and demands specialized expertise.

Reskilling the Workforce: Continuous workforce training is critical. Employees need to upskill from manual tasks to roles managing, maintaining, and programming robotic systems, requiring significant commitment from both employer and employee.

Cyber-Security: As factories become more connected ("Industry 4.0"), securing robotic networks and the data they generate from cyber threats becomes paramount.

Looking forward, BMW invests heavily in the evolution of its BMW Robot Workers:

AI & Machine Learning Integration: Enhancing vision systems for better defect detection, enabling predictive maintenance for robots themselves, and optimizing paths and tasks dynamically using real-time data.

Advanced Mobility & Perception: Developing robots with better spatial awareness for more complex navigation in dynamic human-robot environments (improved AMRs).

Dexterity & New Applications: Research into robotic hands with finer manipulation capabilities for previously impossible-to-automate tasks.

Cloud Robotics & Big Data: Leveraging cloud platforms to share learnings across global factories, enabling faster deployment of optimized robotic processes.

FAQs: Your Questions on BMW Robot Workers Answered

Are BMW Robot Workers replacing human jobs?

BMW maintains that automation aims to augment human capabilities, not simply replace jobs. The focus is on enhancing productivity, quality, and safety. While the nature of jobs is changing (fewer physically demanding roles, more high-skill tech roles like robot programming and oversight), BMW has historically increased its overall workforce globally as production volumes grow. Retraining and upskilling programs are vital components of their strategy to transition the workforce alongside automation.

What happens if a BMW Robot Worker malfunctions?

BMW factories implement multiple safety protocols. Robots have sophisticated onboard diagnostics and sensors. Collaborative robots (cobots) are designed with force/torque limits; unexpected contact triggers an immediate safety stop. Workcells often have perimeter monitoring (laser scanners, light curtains). If a critical malfunction occurs, automated stations stop, and alerts notify skilled technicians who diagnose and resolve the issue. Production lines are designed with redundancies to minimize widespread disruption.

Do BMW Robot Workers build the entire car?

No. Highly automated systems, particularly BMW Robot Workers, excel in specific areas (e.g., body-in-white welding, paint shop processes, heavy component lifting, logistics, precision inspection). However, final assembly involves numerous intricate tasks requiring dexterity, adaptability, and judgment that current robotics technology finds challenging. Tasks like installing complex wiring harnesses, fitting interior trim parts requiring nuanced alignment, installing windshields without damage, and comprehensive final quality checks involving subjective evaluation still rely heavily on human workers collaborating with automation.

How does BMW ensure its robots contribute to sustainability?

BMW Robot Workers contribute significantly to sustainability goals. Their precision reduces material waste (e.g., excess weld material, paint overspray). Optimized movements lower energy consumption compared to older, less efficient automated systems. Cobots are inherently energy-efficient. Reliable automation helps BMW streamline production closer to demand, reducing overall resource consumption. Furthermore, improved factory efficiency through robotics contributes to reducing the overall environmental footprint per vehicle produced.

Conclusion: The Intelligent Factory Floor

The vision of BMW Robot Workers is no longer science fiction; it's the reality powering the production lines crafting today's luxury vehicles. BMW's approach is a masterclass in strategic automation – leveraging robotic strength, precision, and tirelessness where it matters most, while harnessing human ingenuity, adaptability, and oversight for the tasks that require it. The result is a synergistic manufacturing environment capable of meeting the demands of quality, complexity, and customization in the 21st century. As AI, machine learning, and sensing technologies evolve, the capabilities and collaboration potential of BMW Robot Workers will only deepen, cementing their role as indispensable partners in shaping the future of BMW's legendary driving machines. The true power lies not just in the robots themselves, but in this sophisticated, human-centric integration on the factory floor.