When you picture a robot, a whirring arm welding car frames on an automotive assembly line probably comes to mind. This iconic image is deeply rooted for a reason. But is this perception still accurate? If you've ever wondered "What Percentage Of Robots Work In Factories," the answer might surprise you. While factories remain the undisputed stronghold, the landscape is shifting rapidly. Driven by technological advancements and evolving industry needs, robots are increasingly moving beyond the factory floor into diverse sectors. Understanding this distribution isn't just trivia; it reveals the pulse of automation and AI adoption shaping our global economy and workforce. Today, we'll dissect the numbers and dive deeper than ever before into where robots truly operate.

What Percentage Of Robots Work In Factories: The Stark Reality

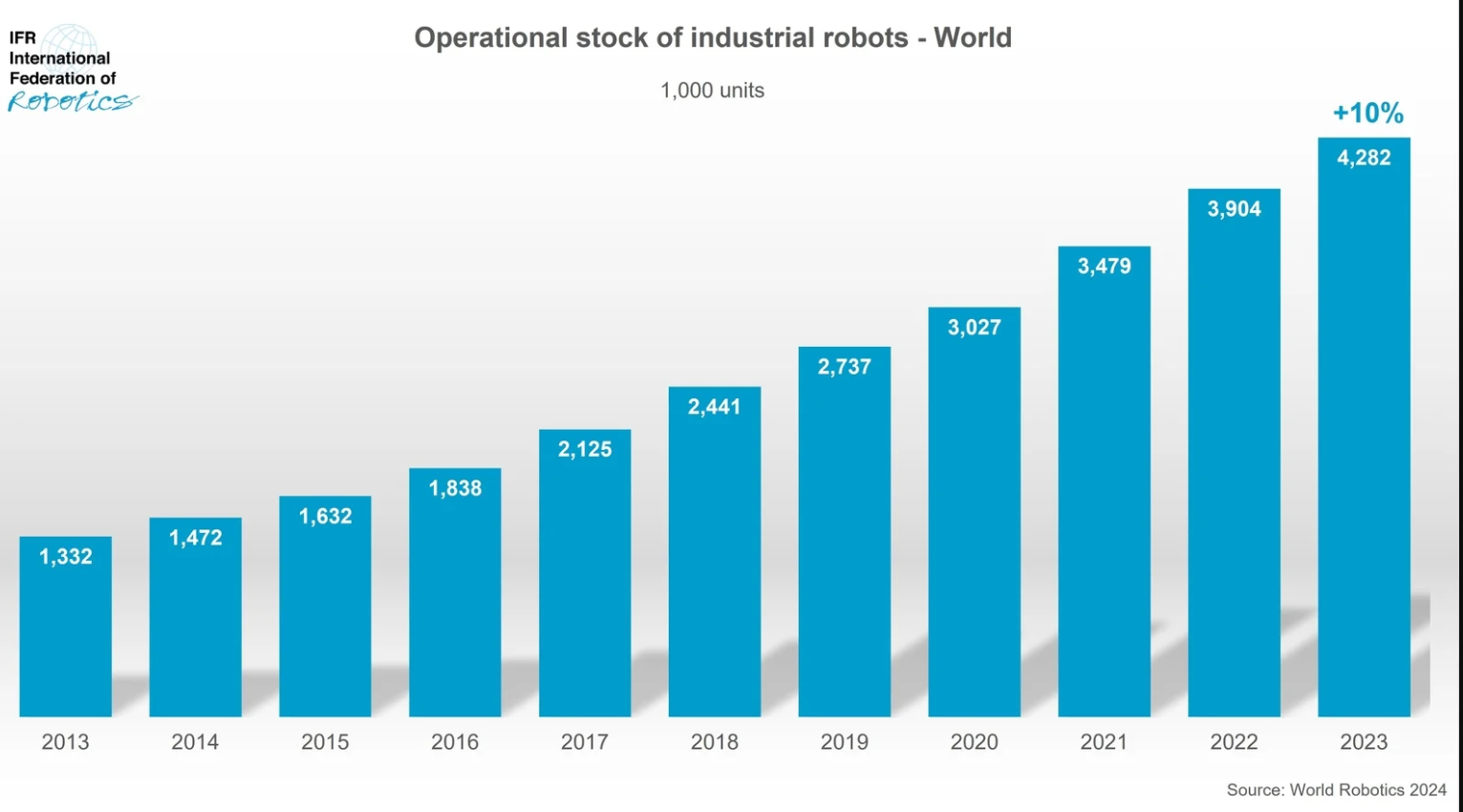

Let's cut to the chase: the dominance is overwhelming. According to the latest comprehensive data from the International Federation of Robotics (IFR), industrial robots designed for factory environments make up the vast majority of operational robots globally. Based on cumulative installations and operational stock analysis:

The overwhelming consensus among experts and industry reports suggests that What Percentage Of Robots Work In Factories falls somewhere between 85% and 90%.

Yes, a staggering 85-90% of all robots that "work" in a professional capacity are employed within factories or structured industrial environments.

This high concentration stems from several key factors:

Longstanding Adoption: Manufacturing industries, particularly automotive and electronics, have been investing heavily in automation for decades. This created a massive installed base.

Structured Environments: Factories offer controlled conditions (lighting, layout, task predictability) that are ideally suited for traditional industrial robots, making implementation cost-effective.

High-ROI Tasks: Repetitive tasks like welding, painting, assembly, palletizing, and machine tending offer clear, quantifiable returns on investment through increased speed, precision, and consistency.

Breaking Down Factory Robotics: It's Not Just Cars

While the percentage in factories is high, what's happening inside those factories is diverse. The IFR meticulously tracks robot installations by industry sector. Here's a more detailed look at the factory landscape:

| Industry Sector | Approximate Share of Industrial Robot Installations | Key Applications |

|---|---|---|

| Automotive & Parts | 25% - 30% | Body welding, painting, final assembly, parts handling |

| Electrical & Electronics | 25% - 28% | Circuit board assembly, testing, precision component handling |

| Metal & Machinery | 10% - 15% | Metal cutting, welding, grinding, foundry applications |

| Plastics & Chemicals | 5% - 8% | Injection molding support, packaging, palletizing |

| Food & Beverage/Pharma | 5% - 7% | Packaging, palletizing, filling, sorting, cleanroom tasks |

| Other Industries Within Factories | 10% - 15% | Aerospace, rubber, woodworking, logistics within plants |

The Key Insight: While automotive remains the single largest driver, the combined electrical/electronics sector often rivals or surpasses it. Crucially, sectors like food & beverage and pharma are experiencing some of the highest growth rates, signaling diversification within the factory domain.

Beyond the Gates: Where the Other 10-15% Work

That leaves roughly 10-15% of professional service robots operating outside traditional factory settings. While smaller in percentage, this segment represents high growth and innovation.

Healthcare: Surgical robots (like Da Vinci), rehabilitation robots, hospital logistics robots, lab automation.

Logistics & Warehousing: AMRs (Autonomous Mobile Robots) for material transport within warehouses and distribution centers, parcel sorting systems.

Agriculture: Autonomous tractors, milking robots, harvesting robots, crop monitoring drones.

Retail & Hospitality: Inventory robots, cleaning robots in malls/airports, food delivery robots in limited settings.

Professional Services: Inspection drones (energy, infrastructure), underwater ROVs, demolition robots.

Public Safety & Security: Bomb disposal robots, patrol robots, firefighting robots.

The complexity of unstructured environments (hospitals, fields, public spaces) has historically been a barrier, limiting the percentage outside factories. However, advances in AI (like machine vision and spatial awareness), sensor technology, and battery life are enabling significant breakthroughs here.

The Future Trajectory: Will the Percentage Change Significantly?

The dominance of factories (likely >80%) isn't disappearing overnight. Reshoring trends and the constant drive for efficiency and resiliency in manufacturing solidify its position.

However, the non-factory sector is projected to grow much faster.

Falling Costs & Increased Capability: Collaborative robots (cobots), drones, and mobile platforms are becoming more affordable and easier to deploy.

Solving Real-World Problems: Labor shortages in agriculture, warehousing, and healthcare create strong demand drivers for non-factory automation.

AI Maturation: As AI enables robots to better understand and interact with unpredictable environments (retail aisles, hospital corridors, farm fields), adoption will accelerate.

This means while the raw number of robots in factories will keep growing substantially, the percentage working outside factories is expected to steadily increase over the next decade. Future estimates suggest the non-factory share could potentially double within the next 10-15 years, significantly shifting the current 85-90% figure.

A prime example of the evolving factory role where cutting-edge AI meets industrial automation is seen in companies like BMW. The integration isn't just about arms welding; it's about intelligent systems optimizing entire production lines and creating sophisticated new job opportunities.

Inside BMW Robotics Jobs: Where AI & Automation Fuel Elite CareersFAQs About Robot Workforce Distribution

Q1: If factories have 85-90% of robots, does that mean service robots are failing?

Not at all. While vastly outnumbered currently, the non-industrial service robot sector is experiencing explosive growth, fueled by AI and mobile platforms. Their challenges (unstructured environments) are different, not insurmountable.

Q2: What counts as a "robot" in these statistics?

This is crucial. When asking "What Percentage Of Robots Work In Factories", most reliable figures (like IFR data) define "Industrial Robots" as: "automatically controlled, reprogrammable, multipurpose manipulators, programmable in three or more axes". Service robots are machines performing useful tasks semi- or fully autonomously outside industrial automation. Drones, AMRs, and surgical robots fall here. Simple fixed automation often isn't counted as a "robot".

Q3: Which country uses the most robots per factory worker?

South Korea, Singapore, and Japan consistently top the charts for robot density (number of robots per 10,000 human workers in manufacturing), according to the IFR. This further emphasizes the intense concentration within global manufacturing hubs.

Q4: Will non-factory robots eventually dominate?

While unlikely to surpass industrial robot numbers soon, their economic impact and visibility in daily life will certainly grow dramatically. The "percentage" question in absolute terms might slowly shift, but factories will remain the powerhouse of professional robotics for the foreseeable future.

Conclusion: Asking "What Percentage Of Robots Work In Factories" reveals a core truth about automation today: factories are still the undisputed home for the vast majority (85-90%) of working robots. This is driven by decades of investment, optimal task environments, and proven ROI in sectors like automotive and electronics. However, dismissing other sectors would be a mistake. The 10-15% working in healthcare, logistics, agriculture, and beyond represent the frontier of robotics innovation, driven by AI and solving increasingly complex problems. This segment is growing faster than the industrial base. While factories will remain dominant in absolute deployment for years, the world beyond the factory gates is where robotics will become increasingly personal, visible, and transformative in our everyday lives and other critical sectors. The future of work, across all environments, will be shaped by this evolution.