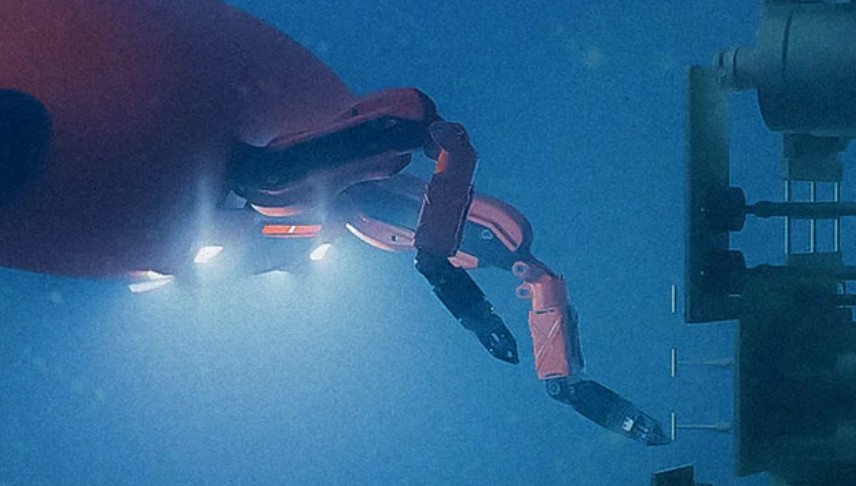

Imagine reaching into the crushing darkness of the Mariana Trench, repairing a pipeline a mile beneath stormy waves, or delicately transplanting coral onto a dying reef – tasks utterly impossible for human hands. This is the extraordinary domain of the Underwater Robotic Arm. More than just metal limbs, these sophisticated manipulators are the essential "hands" of remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs), extending human capability into the planet's final frontier. Powered by increasingly intelligent AI systems, modern Underwater Robotic Arms are revolutionizing ocean exploration, industry, and environmental protection, transforming our ability to interact with and understand the vast, hidden world beneath the waves.

What Exactly is an Underwater Robotic Arm?

An Underwater Robotic Arm is a highly engineered, articulated manipulator system specifically designed to operate in the challenging subsea environment. Unlike industrial robots on land, these arms must contend with immense pressure, corrosive saltwater, near-freezing temperatures, limited visibility, and the fundamental barrier of remote operation, often via an umbilical cable or intermittent acoustic communication. Their primary function is to perform dexterous tasks – grasping, cutting, turning, cleaning, sampling, assembling, and manipulating tools – that replicate or surpass the capabilities of a human diver, but at depths and durations far beyond human limits. Think of them as the critical interface between the remote operator or AI controller and the physical underwater world.

These manipulators are integral to Underwater Robots: Exploring the Depths Beyond Human Limits, serving as their primary means of interaction and intervention.

Anatomy of the Deep: Core Components of an Underwater Robotic Arm

Building an arm that functions reliably kilometers underwater is a feat of engineering. Let's dissect the key components:

1. Joints and Actuators: The Powerhouse of Movement

Joints provide the arm's range of motion (degrees of freedom - DOF), typically mimicking a human arm with shoulder, elbow, and wrist joints. Actuators, housed within pressure-compensated or oil-filled housings, generate the movement. Common types include hydraulic actuators (offering immense power and robustness for heavy-duty work), electric actuators (providing precision and cleaner operation, increasingly favored), and sometimes electro-hydraulic systems for a balance. Sealing these moving parts against water intrusion and pressure is paramount.

2. Manipulator Links & Structure: Built for the Abyss

The links form the skeleton, connecting the joints. These are constructed from high-strength, corrosion-resistant materials like titanium alloys, stainless steel (e.g., 316L), or specialized aluminum alloys. The design prioritizes strength-to-weight ratio to minimize the vehicle's burden while resisting crushing pressure and corrosive seawater.

3. End Effectors: The Versatile "Hands"

This is the tool attached to the wrist, defining the specific task capability. Common end effectors include:

Parallel Jaw Grippers: For general grasping of objects.

Orbital or Rotary Cutters: For severing cables, lines, or soft materials.

Hydraulic Torque Tools: For turning valves or bolts.

Suction Cups: For handling smooth, non-porous objects.

Specialized Sampling Tools: For collecting biological or geological specimens delicately.

Brushes & Water Jets: For cleaning surfaces (e.g., ship hulls, pipelines).

Interchangeable Tool Interfaces: Enabling one arm to perform multiple tasks by swapping tools.

4. Pressure Compensation System: Defying the Crush

Critical for deep-diving arms. Internal components, especially sensitive electronics or lubricated joints, are either housed within oil-filled chambers (where internal oil pressure equals external water pressure) or use flexible membranes (boots) to transfer pressure. This prevents housing collapse and protects delicate parts.

5. Sensors: Providing Feedback and Control

Modern Underwater Robotic Arms incorporate various sensors:

Position & Velocity Sensors (Encoders/Potentiometers): Track joint angles and movement speed.

Force/Torque Sensors (Wrist-Mounted): Measure the forces applied by the end effector, crucial for delicate tasks and preventing damage.

Proximity Sensors: Help avoid unintended collisions.

Vision Systems (Camera Integration): Often the primary feedback for the operator, integrated near the wrist or on the vehicle.

6. Control System: The Brain and Nervous System

This includes the onboard electronics processing sensor data and driving the actuators, and the operator interface topside. Control modes range from direct teleoperation (operator moves a master controller, arm mimics precisely) to supervisory control (operator gives high-level commands, arm's AI handles path planning and obstacle avoidance). Increasingly, AI algorithms handle complex manipulation tasks autonomously.

Beyond Salvage: Cutting-Edge Applications Reshaping Industries

The reach of the Underwater Robotic Arm extends far beyond traditional salvage operations. They are fundamental tools driving innovation across sectors:

Offshore Energy: Maintenance, Construction, and Decommissioning

ROVs equipped with powerful manipulators perform vital tasks on oil and gas platforms, subsea wellheads, and increasingly, offshore wind farms. This includes visual inspection, cleaning marine growth, operating valves, connecting/disconnecting flow lines, installing subsea equipment, and even intricate construction work and decommissioning activities. They drastically reduce the need for hazardous diver intervention.

Scientific Research: Sampling the Unseen

Research ROVs and AUVs use dexterous manipulators to collect fragile biological samples (deep-sea corals, organisms), geological samples (rocks, sediment cores), deploy and retrieve scientific instruments, and conduct delicate experiments on the seafloor. This capability is essential for understanding deep-sea ecosystems, geology, and climate change impacts. They are key components within the diverse range of Underwater Robot Types Transforming Ocean Exploration.

Deep-Sea Mining: The Controversial Frontier

Prototype mining systems rely heavily on large, robust Underwater Robotic Arms equipped with specialized cutting heads or suction devices to collect polymetallic nodules or sulfide deposits from the seabed. The environmental implications are significant, and the manipulator's precision (or lack thereof) is a critical factor in the ongoing debate.

Underwater Infrastructure: Inspection, Repair, and Security

Manipulators inspect and maintain pipelines, telecommunication cables, dams, intake structures, and port facilities. They can perform cleaning, clear debris, conduct non-destructive testing (NDT), and even carry out minor repairs, ensuring critical infrastructure integrity.

Marine Archaeology: Uncovering History with Care

Archaeological ROVs use highly dexterous arms with gentle grippers or specialized tools to carefully excavate shipwrecks, recover artifacts without damage, and document sites with precision, preserving historical context in ways impossible for dredging or large grabs.

Coral Reef Restoration: Precision in Preservation

Emerging applications involve using smaller ROVs with delicate manipulators to plant coral fragments, remove invasive species like crown-of-thorns starfish, or carefully clean reefs affected by pollution or disease, offering new hope for these vital ecosystems.

The AI Revolution: Making Robotic Arms Smarter Underwater

Artificial Intelligence is transforming Underwater Robotic Arm capabilities from remotely operated tools towards intelligent, semi-autonomous systems:

Enhanced Perception & Vision: AI algorithms process complex sonar data, camera feeds (including low-light and murky conditions), and laser scans to build 3D models of the environment, identify objects, and track targets with far greater accuracy than human operators alone.

Autonomous Manipulation Planning: AI can plan collision-free paths for the arm to reach a target object, considering the complex kinematics of the arm and the surrounding environment, significantly reducing operator cognitive load.

Adaptive Grasping & Force Control: Machine learning allows arms to learn how to grasp unfamiliar or delicate objects securely based on visual and force feedback. Precise force control prevents crushing fragile samples or damaging equipment.

Predictive Maintenance: AI analyzes sensor data from the arm's joints and actuators to predict potential failures before they happen, minimizing downtime during critical missions.

Shared Autonomy: Operators provide high-level goals ("Collect that rock sample"), and the AI handles the complex low-level control and adjustments needed to achieve it successfully despite currents or obstacles.

Hurdles in the Hydrosphere: Challenges for Underwater Manipulation

Operating effectively underwater presents unique, persistent challenges:

Communication Latency & Bandwidth: Acoustic communication (the primary method for untethered AUVs) is slow and limited. For tethered ROVs, long umbilicals can introduce signal delays. This makes real-time teleoperation difficult, especially for complex tasks, necessitating increasing autonomy.

Limited Sensory Feedback: While sensors exist, providing the operator with the equivalent of human touch and proprioception underwater remains extremely challenging. Force feedback helps but is not a complete substitute.

Environmental Harshness: Corrosion, biofouling (growth of marine organisms), extreme pressure, and temperature variations constantly degrade performance and increase maintenance needs. Designing truly long-lasting systems is difficult and expensive.

Dynamics & Buoyancy: Water resistance (hydrodynamics) significantly affects arm movement. Moving the arm can disturb the vehicle's stability, requiring constant thruster adjustments. Achieving neutral buoyancy for the arm itself is complex.

High Cost & Complexity: Designing, building, testing, and deploying sophisticated, pressure-rated manipulator systems is inherently costly, limiting widespread adoption, especially for smaller research or environmental groups.

Gazing into the Depths: Future Trends in Underwater Robotic Arms

The future of Underwater Robotic Arms is intertwined with advancements in materials, AI, and robotics:

Increased Dexterity & Miniaturization: Development of more compact, highly dexterous arms (e.g., continuum or snake-like arms) capable of operating in confined spaces like shipwrecks or complex coral structures.

Advanced AI & Machine Learning: More robust AI for fully autonomous complex manipulation tasks, improved object recognition in challenging conditions, and better predictive capabilities.

Improved Haptic Feedback & VR Interfaces: Technologies providing operators with a more intuitive sense of touch and immersion, enhancing control and situational awareness despite latency.

Soft Robotics: Exploration of soft, compliant manipulators inspired by octopus tentacles, potentially offering safer interaction with delicate marine life and environments.

Bio-inspired Designs: Learning from nature to improve efficiency, movement, and interaction underwater.

Swarm Manipulation: Coordinated manipulation tasks performed by multiple smaller vehicles or arms working together on large structures or objects.

Energy Harvesting: Integrating systems to generate power from ocean currents or thermal gradients to extend mission durations.

Frequently Asked Questions (FAQs)

Capabilities vary significantly. Commercial work-class ROV arms routinely operate down to 3,000 - 4,000 meters. Specialized systems, like those on the Nereus hybrid vehicle (lost in 2014) or the manipulators used by the DSV Limiting Factor, are designed for full ocean depth (11,000 meters). The key factors are the pressure compensation system design, material strength, and the vehicle's overall depth rating.

AI tackles core underwater challenges: 1. Perception: It interprets noisy sensor data (sonar, murky video) to identify objects and obstacles far better than simple algorithms. 2. Autonomy: AI plans arm trajectories, avoiding collisions and adapting to currents, reducing reliance on perfect real-time control. 3. Adaptation: Machine learning allows the arm to adjust its grip or force based on feedback, crucial for handling delicate objects or uneven surfaces unseen by the operator. 4. Prediction: AI models anticipate the arm's movement impact on the vehicle's stability, allowing for smoother operation.

Absolutely not! While the most powerful arms are on large work-class ROVs, manipulator technology is scaling down. Smaller inspection-class ROVs often carry one or two 4-5 function electric arms for light intervention. Even some AUVs are being equipped with simple manipulators for tasks like sample collection or instrument deployment. There's also a growing market for portable, lower-cost manipulators used in shallow water research, aquaculture, and education.

Lifespan depends heavily on materials, maintenance, and operational depth. High-end titanium arms on well-maintained ROVs operating in deep water can last 10-15 years or more with regular servicing. Arms in shallower, warmer, or more biofouling-prone environments, or those made with less corrosion-resistant materials, require more frequent maintenance and may have shorter service lives (5-10 years). Proper rinsing after use and scheduled overhauls are critical.

Conclusion: Extending Our Reach into the Blue Heart of the Planet

The Underwater Robotic Arm is far more than a mechanical appendage; it's a symbol of humanity's ingenuity in overcoming the profound challenges of the deep ocean. From enabling the safe exploitation of offshore resources to unlocking the secrets of hydrothermal vents and meticulously restoring damaged reefs, these AI-enhanced manipulators are fundamental to our present and future interaction with the marine environment. As AI, materials science, and robotics continue their relentless advance, the dexterity, intelligence, and accessibility of Underwater Robotic Arms will only increase. They will become even more crucial tools for scientific discovery, sustainable industry, environmental stewardship, and safeguarding underwater infrastructure, ensuring that our reach into the ocean's depths is not just possible, but increasingly precise, powerful, and responsible. The era of intelligent manipulation beneath the waves has truly begun.

SEO Clickbait (60 chars): AI Underwater Robotic Arms: Ocean's Secret Hands Revealed!

Popper URL: /underwater-robotic-arm-guide

SEO Description (160 chars): Discover how AI-powered Underwater Robotic Arms work! Explore their parts, deep-sea mining uses, coral restoration & future trends. The key to unlocking ocean secrets.

Tags: Underwater Robotic Arm, Ocean Robotics, AI Subsea Manipulation