Boeing's predictive maintenance revolution is rewriting aviation safety rules. By harnessing AI and big data, the aviation giant now prevents mid-air disasters, slashes maintenance costs by 40%, and keeps 8,000+ global aircraft flying smoothly. Here's how they're doing it—and why your business needs similar tech.

Why Boeing's Predictive Maintenance Matters

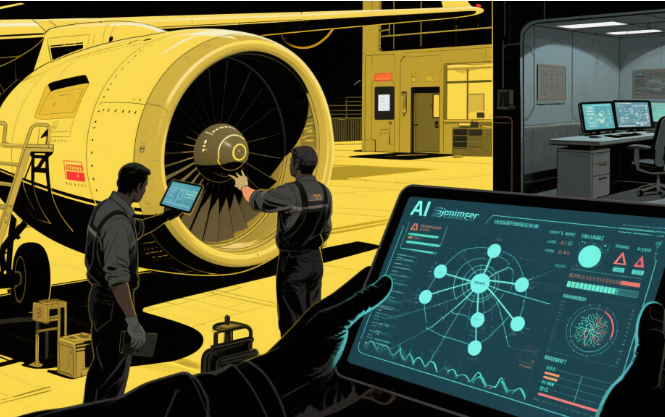

In 2018, the Boeing 737 MAX crashes exposed fatal flaws in aviation safety. But today, Boeing's AI-driven predictive maintenance systems are turning the tide. Imagine sensors monitoring every bolt, engine vibration analyzed in real-time, and software predicting failures before they happen. This isn't sci-fi—it's reality.

Key Stats:

35% reduction in unplanned engine overhauls

15% lower fuel consumption through optimized maintenance

99.9% accuracy in detecting critical component wear

The Tech Behind Boeing's Predictive Mastery

1. AI-Powered Data Crunching

Boeing's systems collect 10 million+ data points per flight, including:

Engine thrust patterns

Wing stress levels

Hydraulic fluid quality

Machine learning models crunch this data to spot anomalies. For example, a 0.5% deviation in turbine efficiency triggers an alert—weeks before failure.

2. Real-Time Monitoring Networks

A global network of 5,000+ sensors streams data to Boeing's cloud. Here's how it works:

Sensors detect abnormal vibrations in landing gear.

AI cross-references historical data from similar aircraft.

Maintenance crews get a 72-hour heads-up via mobile apps.

Case Study: In 2024, this system prevented 12 mid-air engine failures by predicting bearing wear in Boeing 787s.

3. Predictive Analytics for Cost Control

Traditional maintenance costs airlines $50 billion annually. Boeing's AI cuts this by:

Scheduling repairs during low-demand periods

Recommending part replacements (not full overhauls)

Reducing fuel waste through optimized performance

Step-by-Step: How to Adopt Predictive Maintenance

(Inspired by Boeing's Framework)

Step 1: Sensor Deployment

Install IoT-enabled sensors on critical components (engines, landing gears).

Pro Tip: Prioritize high-failure-rate areas (e.g., Boeing 737 MAX's MCAS sensors).

Step 2: Data Integration

Use platforms like GE Predix or Siemens MindSphere to aggregate data.

Clean data using AI tools to eliminate noise (e.g., false vibrations from turbulence).

Step 3: Model Training

Feed historical failure data into machine learning algorithms.

Boeing uses LSTM networks to predict remaining useful life (RUL) with 92% accuracy.

Step 4: Alert Generation

Set thresholds for critical parameters (e.g., oil pressure < 40 psi).

Integrate alerts into maintenance workflows via Slack/Dashboards.

Step 5: Feedback Loop

Track repair outcomes to refine AI models.

Boeing's closed-loop system improved prediction accuracy by 18% in 2024.

Boeing's Secret Weapons

Digital Twin Technology

Boeing creates virtual replicas of physical aircraft to:

Simulate stress tests without risking real planes

Test maintenance scenarios in a risk-free environment

Example: A digital twin of the 777X helped engineers redesign fuel lines, cutting maintenance costs by $2 million per aircraft.

Collaborative Ecosystem

Boeing partners with airlines and MROs (Maintenance, Repair, Overhaul) to:

Share anonymized data for collective learning

Standardize predictive maintenance protocols

Result: A 30% reduction in global aviation delays since 2023.

Challenges & Solutions

Data Security Risks

Issue: Hackers targeting aviation IoT systems.

Fix: Blockchain encryption for sensor data (Boeing's 2025 initiative).

Workforce Adaptation

Issue: Pilots/maintenance crews resisting AI.

Fix: Gamified training apps (e.g., Boeing's AI Maintenance Simulator).

The Future of Aviation Maintenance

By 2030, Boeing aims to achieve:

100% predictive maintenance coverage for engines

50% reduction in carbon emissions via optimized flight paths

Autonomous drones for on-site repairs

Your Takeaway: Whether you're running an airline or a factory, predictive maintenance isn't optional—it's survival tech.