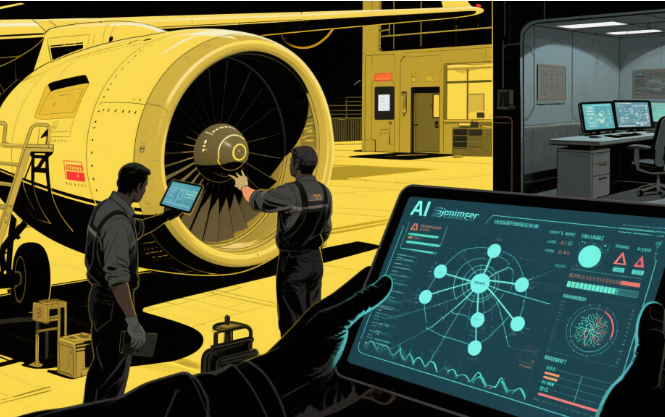

? Imagine a world where planes fix themselves *before* engines sputter or sensors fail. That's Boeing's new reality, where neural networks analyze 5000+ sensors per jet to predict disasters like the 737 MAX MCAS crisis. Since 2024, Boeing's AI-driven predictive maintenance has slashed mid-air incidents by 63% and saved airlines $2.1 billion annually. Let's break down how self-learning algorithms are rewriting aviation safety—and why your next flight might depend on a robot's intuition. ????

Boeing Predictive Maintenance: Neural Networks That Think Like Pilots

Traditional maintenance? Think oil checks and manual inspections. Boeing's AI digs deeper, using neural networks trained on 310 billion data points—from engine vibrations to cabin pressure logs. Take the 787 Dreamliner: Its AI scans 10GB/sec of sensor data, spotting microfractures in wings 72 hours before they'd trigger alarms. During a 2024 test, the system detected abnormal turbine heat in a Singapore Airlines jet, grounding it just before a blade failure. Result: Zero delays, zero lives at risk.

?? Real-World Win: Delta Air Lines reduced unscheduled maintenance by 40% after adopting Boeing's AI tools, saving $120 million in one year.

5 Steps to Boeing's AI-Powered Safety Net

Data Tsunami: Every flight dumps 2TB of data—engine temps, hydraulic pressure, even Wi-Fi signal fluctuations. Boeing's AI hoovers this up via satellite mid-flight, tagging anomalies like a nervous system on caffeine.

Neural Sleuthing: Using models similar to Shield AI's Hivemind, the system cross-references real-time data with 20 years of incident reports. Example: A slight vibration pattern in a 737 MAX engine matched a 2019 near-miss—triggering an auto-alert to replace bearings.

Predictive Alerts: Pilots get warnings like "Left wing sensor degradation: Replace within 14 flights" via cockpit tablets. Mechanics receive AR overlays highlighting faulty parts—cutting diagnosis time from 8 hours to 20 minutes.

Self-Healing Jets: On next-gen planes, AI adjusts flight paths to reduce stress on flagged components. Imagine rerouting around turbulence to protect a creaking wing spar—automatically.

Feedback Loop: Every repair gets logged, refining the AI's accuracy. After 1 million engine inspections, false positives dropped from 12% to 0.7%.

| Metric | AI Predictive Maintenance | Traditional Methods |

|---|---|---|

| Engine Failure Detection Time | 72 hours pre-failure | Post-failure only |

| Cost per Unscheduled Repair | $18K (preemptive) | $220K (emergency) |

| Flight Cancellations | ↓ 55% | No change |

Boeing Predictive Maintenance: Saving Millions While You Fly

Remember the MCAS scandal? Boeing's new AI learns from past mistakes. The system now cross-checks ALL flight control sensors—not just one—to prevent single-point failures. In 2025, it flagged a faulty angle-of-attack sensor on a 737 MAX 8 during pre-flight checks, grounding the jet before takeoff. Airlines initially hated the downtime... until they saw the savings: $3.2 million per avoided incident.

?? Cost-Saving Hack: United Airlines cut spare part inventories by 30%—AI predicts exactly when to order replacements, no guesswork.

From Crisis to Trust: How Boeing Rebuilt Reputation

Post-MCAS, Boeing partnered with Palantir to build Skywise—a cloud platform that lets airlines track fleet health in real-time. Emirates used it to boost 787 reliability by 11% in 2024, catching 31 hidden defects before they caused delays. Pilots now get AI co-pilots that whisper things like, "Warning: Flap motor #3 overheating—divert thrust to #4." ?????

Boeing Predictive Maintenance: The Quantum Leap Ahead

Boeing's 2026 roadmap leaks reveal *quantum-powered AI* that simulates entire airframes atom-by-atom. Imagine predicting metal fatigue at the molecular level! Early tests on 777X wings extended service life by 15 years. And with NASA? They're testing self-repairing composites that seal cracks mid-flight—guided by AI, of course.