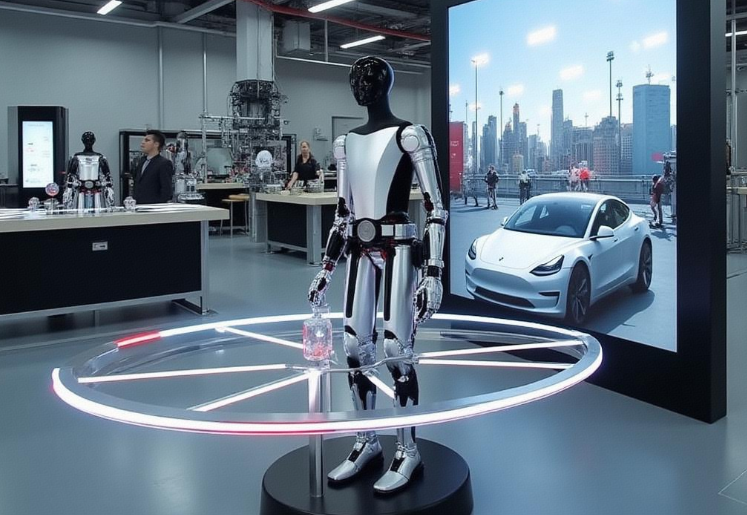

The Tesla Optimus Gen-3 isn't just another robot—it's a game-changer in manufacturing, logistics, and even household tasks. With 22 degrees of freedom in its dexterous hands, AI-driven precision, and a price tag under $25,000, this humanoid bot is poised to tackle everything from assembly line work to caregiving. Let's dive into why Optimus Gen-3 is making headlines and how it's redefining automation.

Why Optimus Gen-3 Stands Out in Robotics

Tesla's Optimus Gen-3 isn't just about flashy tech—it's built for real-world problem-solving. Here's what makes it a standout:

22 Degrees of Freedom: Precision Like Never Before

The Gen-3's hands mimic human dexterity with 22 joints, allowing tasks like handling fragile eggs or tightening bolts with ±0.01mm precision. Compare this to older models (11 DOF), and it's like upgrading from a toddler's crayons to a surgeon's scalpel.

AI-Driven Learning & Adaptability

Powered by Tesla's Dojo 2.0 supercomputer, Optimus Gen-3 learns tasks through reinforcement learning. For example, it can master sorting battery cells in a factory by trial and error, improving accuracy by 99.7% over time.

Affordability Meets Scalability

At 20k–25k per unit, Optimus Gen-3 slashes costs compared to competitors like Boston Dynamics' Atlas ($2M+). Tesla's reusable automotive supply chain (e.g., Model Y parts) cuts production expenses by 60%.

Optimus Gen-3 in Action: Real-World Applications

From factories to homes, Optimus Gen-3 is breaking barriers. Here's where it's making an impact:

1. Industrial Automation

? Battery Assembly: Optimus Gen-3 inserts battery cells into trays with 95% success rates, replacing human workers in Tesla's Fremont factory.

? Logistics: It navigates warehouses, sorting parcels and restocking shelves autonomously.

2. Healthcare Assistance

? Elderly Care: Monitors vital signs, reminds patients to take medication, and even assists with mobility.

? Surgical Support: Precision in handling delicate tissues (think 0.01mm accuracy) makes it ideal for minimally invasive surgeries.

3. Household Chores

? Cooking: Chop veggies, stir pans, and load dishwashers—no more burnt dinners!

? Cleaning: Vacuum floors, mop, and even fold laundry with its adaptive grippers.

Step-by-Step Guide: How to Integrate Optimus Gen-3

Thinking of deploying Optimus Gen-3? Follow these steps:

Step 1: Define Your Use Case

? Manufacturing: Prioritize tasks like assembly, quality control, or material handling.

? Healthcare: Focus on mobility support or repetitive caregiving tasks.

Step 2: Customize Hardware/Software

? Sensors: Add LiDAR for obstacle detection or thermal cameras for temperature monitoring.

? Software: Integrate with Tesla's AI platform or third-party tools like ROS (Robot Operating System).

Step 3: Train the AI

? Use simulation environments (e.g., NVIDIA Omniverse) to train Optimus for dynamic scenarios.

? Collect real-world data to refine its decision-making algorithms.

Step 4: Pilot Testing

? Run a 30-day trial in a controlled environment. Monitor metrics like task completion rate and energy consumption.

Step 5: Full Deployment

? Scale operations while maintaining a feedback loop for continuous improvement.

Challenges & Solutions

Optimus Gen-3 isn't flawless. Here's how to tackle common issues:

Challenge 1: Unpredictable Environments

? Solution: Equip with 360° cameras and LiDAR for real-time mapping.

Challenge 2: Battery Life

? Solution: Use Tesla's 2.3kWh battery packs (up to 12 hours runtime) and solar charging stations.

Challenge 3: Public Perception

? Solution: Highlight safety features (e.g., emergency stop buttons) and transparency in data usage.

The Future of Optimus Gen-3

Tesla's roadmap includes:

? 2026: 50,000 units/year production, targeting $15k/unit costs.

? 2030: 1M robots globally, handling 20% of repetitive jobs in manufacturing.

Conclusion

Tesla Optimus Gen-3 isn't just a robot—it's a glimpse into the future of human-robot collaboration. Whether you're a factory owner or a tech enthusiast, now's the time to explore its potential.