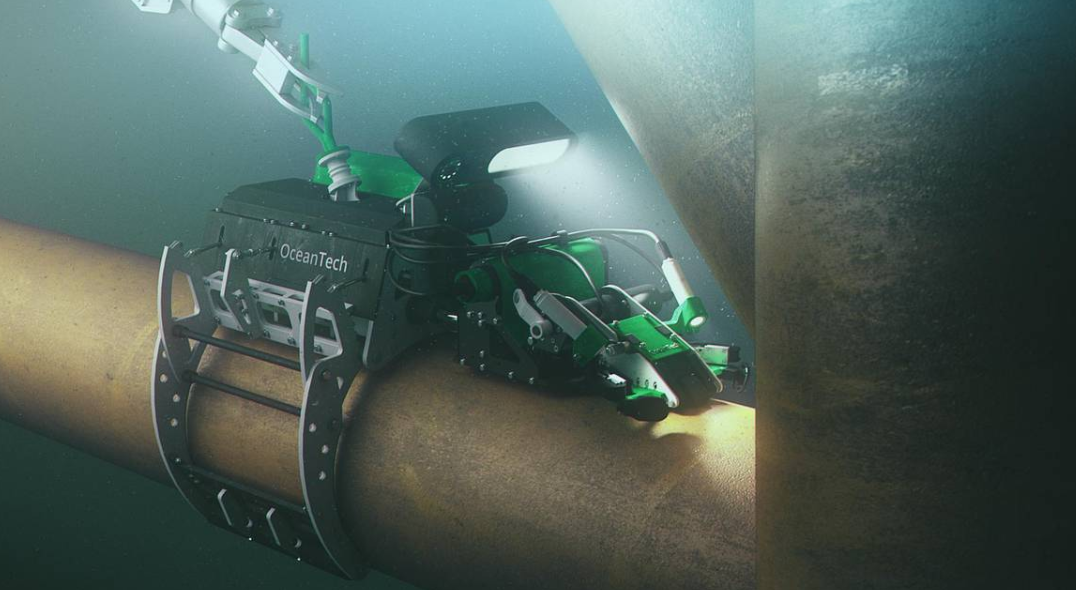

Beneath the waves lies a world vital to our planet's health, global economy, and energy supply, yet it remains one of the most challenging and hazardous environments for humans to access. Enter Underwater Inspection Robots – sophisticated, remotely operated, and increasingly autonomous machines transforming how we explore, maintain, and protect subsea assets and ecosystems. Powered by cutting-edge AI, these robotic guardians are revolutionizing safety, efficiency, and data quality in the deep, making the invisible depths visible and actionable like never before.

The Critical Role of Underwater Inspection Robots

Traditional underwater inspections often involved sending human divers into potentially dangerous conditions – deep waters with crushing pressure, poor visibility, strong currents, and cold temperatures. Tasks could be time-consuming, costly, and limited by human endurance and perceptual capabilities. Underwater Inspection Robots, primarily Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs), overcome these limitations dramatically.

They provide unparalleled access to submerged infrastructure (pipelines, cables, offshore platforms, dams, ship hulls) and delicate marine environments, performing critical visual and structural surveys without exposing human life to risk. The core value proposition of modern Underwater Inspection Robots isn't just depth access; it's the ability to capture high-fidelity data consistently, efficiently, and safely, enabling proactive maintenance, preventing catastrophic failures, reducing operational downtime, and significantly lowering costs over the asset lifecycle.

Unpacking the Tech: How Underwater Inspection Robots Work

Modern Underwater Inspection Robots are marvels of engineering, integrating diverse technologies to navigate, perceive, and act in an environment that blocks radio waves and GPS signals. Key components include:

1. Propulsion and Maneuverability Systems

Underwater Inspection Robots utilize vectored thrusters, typically electric or hydraulic, arranged strategically (4, 5, 6, or even 8 thrusters) to allow precise movement in all axes – surge (forward/backward), sway (left/right), heave (up/down), yaw (rotation), and sometimes roll and pitch. Advanced control systems ensure stability even in challenging currents.

2. Sensor Suites: The Robot's "Senses"

High-Definition Cameras: Multiple cameras (often 4K or higher) provide close-up inspection views and wide-angle navigation perspectives, mounted on pan-tilt units.

Sonar Systems: Crucial for low-visibility or night operations. Imaging sonars (like DIDSON or BlueView) create near-photo-like pictures, while multibeam or sidescan sonars build detailed bathymetric maps of the seafloor or structures.

Positioning and Navigation: Combine data from Inertial Measurement Units (IMUs), Doppler Velocity Logs (DVLs), USBL (Ultra-Short Baseline) or LBL (Long Baseline) acoustic positioning systems (relative to a surface vessel or seabed transponders), and depth sensors to precisely locate the vehicle.

Additional Sensors: CTDs (Conductivity, Temperature, Depth), environmental sensors (dissolved oxygen, turbidity), laser scalers (for accurate size measurement), Cathodic Protection probes (CP), and methane detectors are common for comprehensive surveys.

3. Data Transmission: The Umbilical and Acoustic Modems

ROVs rely on a tethered umbilical cable. This heavy-duty cable provides power from the surface vessel/control station and carries data – high-bandwidth HD video and sensor data upwards, and critical control commands downwards. Some AUVs use fiber-optic micro-tethers for high-bandwidth data transfer when docked or during mission uploads. For true autonomy, AUVs rely on acoustic modems for low-bandwidth communication (command updates, data bursts, status) over longer distances.

4. Manipulators and Tooling

While not always equipped for pure inspection tasks, many Underwater Inspection Robots feature one or more ROV manipulator arms (typically hydraulic or electric 5/7-function types like Schilling or Kraft Robotics arms). These allow them to perform light intervention – clearing debris, placing sensors, attaching markers, or carrying specialized inspection tools like Non-Destructive Testing (NDT) probes (Ultrasonic Thickness gauging - UT, Alternating Current Field Measurement - ACFM, etc.).

Where Underwater Inspection Robots Make a Splash: Key Applications

The versatility of Underwater Inspection Robots sees them deployed across numerous sectors:

Offshore Oil & Gas

Undoubtedly the largest market: regular inspection of drilling rigs, production platforms, subsea trees, manifolds, flowlines, risers, pipelines for corrosion, damage, marine growth, cathodic protection levels, and structural integrity. Essential for safety compliance (e.g., API RP 2D/2F standards) and life extension. Underwater Inspection Robots are indispensable workhorses.

Maritime & Shipping

Ship hull inspection for damage, biofouling (without costly drydocking), propeller and thruster inspection, port infrastructure maintenance (pilings, seawalls), salvage operations, and pre-purchase surveys. Learn more about how AI drives precision in underwater tasks in our article on Underwater Welding Robots.

Renewable Energy (Wind & Hydro)

Foundation inspection for offshore wind turbines (pre- and post-installation, scour monitoring), cable surveys, tidal turbine inspections, dam infrastructure inspection (spillways, intakes), and reservoir assessments.

Aquaculture

Inspecting nets for tears and biofouling, monitoring fish health and stock levels, observing feeding systems, and assessing the structural integrity of cages and moorings.

Scientific Research & Environmental Monitoring

Mapping coral reefs, studying marine life behavior (less invasive than manned subs), monitoring pollution (chemical spills, plastics), seabed mapping for geology or archaeology, and exploring extreme environments (hydrothermal vents). Discover the broader scope in our piece on Unveiling the Ocean's Secrets.

Civil Infrastructure & Public Safety

Inspecting bridge pilings, dam walls, water intake structures, pipelines (water, sewer), underwater portions of nuclear facilities, locating submerged vehicles or evidence, and port security sweeps.

The AI Revolution: Smartening Up Underwater Inspection Robots

While robotics provided the platform, Artificial Intelligence is injecting transformative intelligence into Underwater Inspection Robots:

1. Automated Data Analysis & Anomaly Detection

Processing the terabytes of video, sonar, and sensor data collected during a survey was traditionally manual, slow, and prone to human error. AI algorithms, particularly Convolutional Neural Networks (CNNs) trained on vast datasets of imagery, are revolutionizing this. They can automatically detect and classify potential defects – cracks, corrosion, marine growth, denting, buckling – with increasing accuracy. This drastically reduces analysis time from days/weeks to hours/minutes and flags critical issues faster.

2. Enhanced Navigation & Autonomy

AI enables smarter path planning and obstacle avoidance, allowing AUVs and semi-autonomous ROVs to navigate complex structures like subsea installations more efficiently and safely. Machine learning helps vehicles adapt to changing currents or unseen obstacles. Simultaneous Localization and Mapping (SLAM) algorithms, supercharged by AI, create highly accurate 3D models of environments in real-time.

3. Predictive Maintenance Insights

By integrating AI-analyzed inspection data with historical records, operational parameters, and environmental data, predictive maintenance models can forecast the remaining useful life of components (e.g., pipeline sections, cathodic protection anodes) and prioritize interventions, optimizing maintenance schedules and budgets.

4. Human-Robot Teaming

AI facilitates more intuitive control interfaces (voice commands, gesture recognition for manipulator arms) and collaborative decision-making, where the AI highlights areas of interest for the human operator to focus on, enhancing overall mission productivity and situational awareness.

The Future Is Deeper: Emerging Trends

The evolution of Underwater Inspection Robots is accelerating:

Increased Autonomy: Move towards collaborative swarms of smaller, specialized AUVs and ROVs capable of adaptive mission execution with minimal supervision. "Underwater Cloud" concepts with resident seafloor docking stations for long-term deployment.

Hybrid AUV/ROVs (HROVs): Combining AUV range/survey efficiency with ROV dexterity/intervention capability in a single platform.

Advanced Sensing & Resolution: Hyper-sensitive chemical sensors, low-cost miniaturized sensors, higher resolution cameras/sonars integrated with photogrammetry and laser scanning for centimeter-accurate Digital Twins of assets.

AI Integration at the Edge: Processing data onboard the vehicle using powerful, low-power AI chips, enabling real-time anomaly detection and decision-making without constant surface communication.

Manipulator Dexterity & AI-Assisted Control: Development of more dexterous, force-feedback-enabled arms and AI systems that can semi-automate complex manipulation tasks like operating valves or conducting NDT inspections.

Bio-Inspired Designs: Robots mimicking the efficient propulsion and maneuverability of fish or cephalopods for lower energy consumption and quieter operation in sensitive environments.

Frequently Asked Questions (FAQs)

Q: Are Underwater Inspection Robots replacing diver jobs?

A: Primarily, they are enhancing diver safety and efficiency, not wholesale replacing them. Robots handle the most hazardous, deep, or repetitive inspection tasks, keeping divers out of high-risk situations. Divers remain crucial for complex repairs and tasks requiring extreme dexterity or decision-making in highly variable environments. Robots act as powerful force multipliers.

Q: What are the main limitations of current Underwater Inspection Robots?

A: Key limitations include:

Power: ROVs rely on tethers; AUVs have limited battery life impacting mission duration.

Bandwidth: Transmitting HD video and large sensor datasets through water acoustically is very slow; tethers overcome this but limit range.

Dexterity & AI Maturity: While improving, robotic manipulators still lack the fine dexterity of human hands, and AI for complex underwater scene understanding isn't perfect yet.

Cost: Highly capable ROV/AUV systems, specialized tooling, and operation support vessels are significant investments, though ROI is substantial for industrial applications.

Q: How much does an Underwater Inspection Robot cost?

A: Costs vary immensely based on capabilities. Small inspection-class ROVs (e.g., for hull inspections) can start around $25,000. Medium-sized Work-Class ROVs used offshore typically range from $500,000 to over $2 million per system, excluding the deployment vessel. Large AUVs for deep-sea surveying can cost several million dollars. Most complex inspections are performed via service providers charging daily rates ($10,000 to over $50,000+ depending on depth, equipment, and vessel).

Q: Can Underwater Inspection Robots operate in rivers or very shallow water?

A: Yes, absolutely. There are smaller, portable ROVs specifically designed for shallow water inspections (rivers, lakes, dams, intake structures, marinas). Some utilize buoyancy or thruster configurations optimized for shallow operations and maneuver around debris. Miniaturization continues to make robots viable for increasingly confined spaces.

Conclusion: Plunging Towards a More Accessible Deep

Underwater Inspection Robots are no longer niche tools but fundamental enablers for industries operating beneath the surface. They dramatically enhance human capabilities, providing safer, more efficient, and increasingly intelligent access to the underwater world. The fusion of robotics with AI is unlocking unprecedented levels of data understanding and autonomous operation, paving the way for predictive maintenance, optimized operations, and deeper exploration of our ocean frontier. As technology continues to mature – offering greater autonomy, enhanced dexterity, and more powerful onboard AI – the reach, impact, and capabilities of Underwater Inspection Robots will only expand, solidifying their role as indispensable guardians of both our critical subsea infrastructure and the marine ecosystems we strive to understand and protect.