Imagine: Deep within a labyrinth of rock, far beyond where human lungs can breathe or bodies can endure the crushing pressure, a tireless, intelligent presence navigates the darkness. It maps uncharted veins of ore with laser precision, drills through the densest rock with unyielding force, and transports tonnes of mineral wealth to the surface – all without a human operator in sight. This isn't science fiction; it's the dawn of the Mining Robot revolution. While traditional mining faces escalating dangers, plummeting ore grades, and crippling environmental and social pressures, AI-powered robotics are emerging as the indispensable key to unlocking essential resources safely, efficiently, and sustainably. This article isn't just about machines replacing humans; it's about defining the technologies transforming how we explore and extract Earth's riches, and why they represent the *only* viable path forward.

Unearthing the Evolution: How Mining Robots Emerged

The journey towards autonomous mining began decades ago, initially driven by a simple need: safety. Mines are inherently perilous environments plagued by cave-ins, toxic gas, dust explosions, and equipment collisions. Sending machines into the most dangerous zones first became a logical imperative. Early innovations were rudimentary – basic remote-controlled vehicles that barely scratched the surface of autonomy. Think of giant teleoperated LHD (Load-Haul-Dump) units, reliant entirely on a human driver miles away via clunky video feeds and controls.

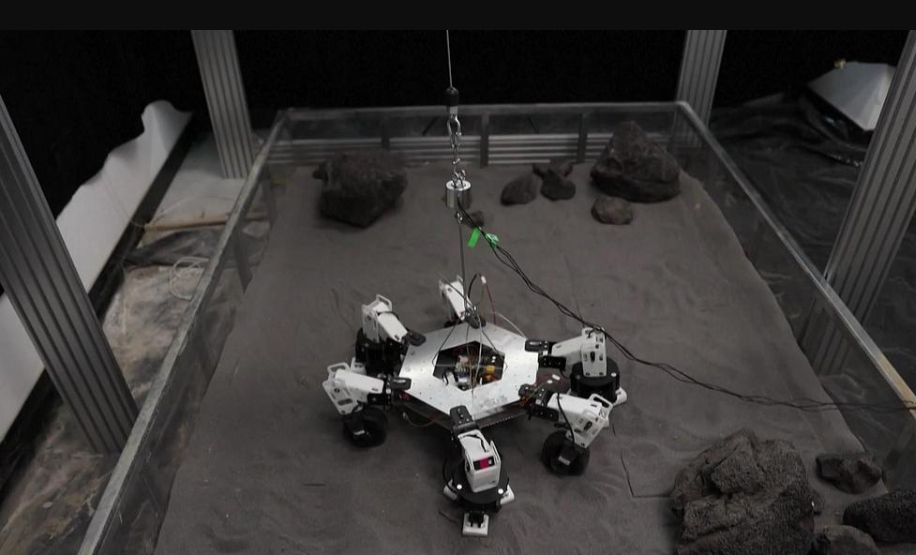

The true inflection point came with the convergence of exponential advancements in four key areas: sensor technology (LiDAR, RADAR, multispectral imaging, inertial navigation), processing power (enabling real-time data analysis onboard the robot), machine learning/AI (allowing machines to perceive, navigate, and make decisions in chaotic environments), and robust mechanical engineering (creating machines durable enough to withstand harsh mining conditions for extended periods). Modern Mining Robots are sophisticated systems integrating these technologies, moving far beyond teleoperation towards genuine, supervised autonomy.

Inside the Cutting-Edge: The Core Tech Stack of a Modern Mining Robot

What makes today's Mining Robots so revolutionary? It's a layered approach:

1. Sensory Overload (Perception): The Mining Robot's Eyes and Ears

Mining Robots deploy a sensor suite far exceeding human capability. Multi-channel LiDAR creates high-resolution 3D point clouds of tunnels and stopes in near-total darkness. RADAR penetrates dust clouds that would blind cameras and human eyes. Hyperspectral sensors analyse rock faces instantly, identifying mineral composition and ore grade in real-time, crucial for selective mining. Stereo cameras provide depth perception, while inertial measurement units (IMUs) track precise movement and orientation even when GPS is unavailable underground. This fusion of sensory data creates a constantly updated digital twin of the mine environment.

2. The AI Brain: Processing, Navigation, and Decision-Making

Raw sensor data is meaningless without sophisticated processing. Onboard computers, increasingly powerful and ruggedized, run complex SLAM (Simultaneous Localization and Mapping) algorithms. These algorithms allow the Mining Robot to pinpoint its location within the mine with centimetre-level accuracy while simultaneously building and updating the mine map. AI algorithms process geological data from hyperspectral sensors to make instant decisions: "Is this rock high-grade ore? Waste? Geologically hazardous?" Pathfinding algorithms plot optimal, collision-free routes through dynamic environments filled with moving equipment, debris, and changing rock formations. Unlike teleoperated machines, modern systems can react autonomously to unforeseen obstacles within predefined safety parameters.

3. Brute Force Meets Precision: End Effectors & Locomotion

Intelligence needs a powerful body. Mining Robots leverage specialised locomotion systems tailored to brutal terrains: heavy-duty tracks with active suspension for underground haul roads, articulated legs for navigating steep, unstable slopes, or specialised wheel designs for soft overburden. Their "hands" – the end effectors – are task-specific: enormous hydraulic drills capable of precision boring, powerful robotic arms with cutting tools, massive buckets for loading and hauling tens or hundreds of tonnes, or highly dexterous manipulators for intricate tasks like inspection or sampling. The force exerted is immense, yet controlled with increasing finesse thanks to advanced hydraulics and force-feedback systems.

4. The Digital Nervous System: Connectivity and Control

Seamless communication is vital, especially in signal-challenged underground environments or vast open pits. Mining Robots rely on robust meshed networks combining high-bandwidth Wi-Fi, leaky feeder systems, ultra-reliable but lower-bandwidth LPWAN (Low-Power Wide-Area Network) technologies, and even tethered fibre optics. Data streams constantly from robots to centralized Mission Control Centers located safely on the surface. Here, human supervisors monitor fleet health, productivity metrics, and overall mine activity via sophisticated dashboards. While robots operate autonomously for routine tasks, humans remain "in the loop" for high-level planning, exception handling, and mission overrides.

Titans of the Underground: Who's Leading the Mining Robot Charge?

The Mining Robot landscape features established industrial giants, specialised robotics firms, and technology powerhouses:

Komatsu (Exploration Robotics Technologies partners): Pioneers with their Frontrunner Autonomous Haulage System (AHS), controlling vast fleets of autonomous trucks at mines like Rio Tinto's Gudai-Darri, leading to massive productivity gains (~30%) and safety improvements.

Caterpillar (CAT): Major player in autonomous trucks and drills via their Command system. Their partnership with Rio Tinto is legendary, particularly at the Koodaideri mine.

Sandvik & Epiroc: Dominating underground autonomous solutions. Sandvik's AutoMine and Epiroc's Rig Control System enable complete autonomy for LHDs, drill rigs, and bolting equipment, allowing true unmanned production shifts.

FLANDERS (MineWare): Specialized in payload monitoring and optimisation software crucial for autonomous haulage fleet efficiency.

NASA (MMM Project): While focused on space exploration, their development of highly autonomous, robust Mining Robots capable of operating in extreme environments with minimal supervision (Beyond Humans: What REALLY Defines Exploration Robots) directly influences terrestrial mining robotics, pushing the boundaries of remote operability.

The Irrefutable Case: Why Robotics DOMINATE Future Mining

The shift towards Mining Robots isn't a fad; it's driven by undeniable advantages solving critical industry pain points:

Revolutionizing Safety: Removing humans from hazardous zones (underground faces, unstable slopes, blast areas, deep pits) eliminates the most significant cause of fatalities and life-altering injuries. This is the primary, non-negotiable driver.

Unlocking Productivity 24/7/365: Robots don't need shift changes, meal breaks, or sleep. They operate continuously in designated areas, maximizing asset utilisation. Studies consistently show autonomous haul trucks operate significantly more hours per year than manned ones.

Conquering the Grade Problem: As easily accessible, high-grade ore deposits dwindle, mining moves to lower grades at greater depths. The economics of extracting these reserves hinge on vastly reduced operational costs – which autonomy delivers through higher efficiency and reduced labour overheads.

Precision Extraction & Less Waste: Real-time ore grade sensors and sophisticated controls enable highly selective mining. Robots can precisely delineate ore boundaries, extracting valuable material while leaving low-grade or waste rock behind. This drastically reduces haulage costs and processing volume, significantly improving resource efficiency and minimizing environmental footprint.

Consistent Quality & Asset Longevity: AI-controlled equipment operates at optimal parameters consistently, reducing over-processing and equipment strain. Precise drilling and blasting lead to better fragmentation, improving downstream processing efficiency and extending the life of crushers and mills.

Navigating the Skilled Labour Crisis: Mining faces a chronic shortage of skilled operators willing to work in remote, hazardous conditions. Mining Robots mitigate this crisis, allowing existing skilled personnel to oversee larger operations remotely from safer, more comfortable control centres.

Gazing Deeper: The Shocking Horizon for Mining Robots

The evolution is accelerating. What seems cutting-edge today is merely the foundation for tomorrow's capabilities:

True Self-Learning & Advanced Exploration: The next leap is unsupervised learning. Imagine a Mining Robot entering a completely unknown tunnel network. Using AI trained on vast geological datasets, it could independently map the geology, identify anomalies, locate the richest ore bodies, and make strategic decisions about optimal extraction points without detailed human pre-programming for that specific scenario, significantly enhancing capabilities described in Exploration Robotics Technologies Inc: The Secret Architects.

Multi-Robot Ecosystems & Swarm Intelligence: Future mines will operate like intelligent beehives. Heterogeneous fleets (drill rigs, LHDs, haul trucks, survey drones) will communicate continuously. Swarm algorithms will enable them to coordinate tasks seamlessly – one robot detects a rich vein, instantly directing others nearby for extraction, while another maps ventilation, optimizing flow based on activity in real-time.

Space Mining Prototypes Become Terrestrial Pioneers: Projects like NASA's MMM (Moon-to-Mars Mission) are developing ultra-autonomous, self-repairing robots designed to operate in the ultimate remote, high-risk environment. The radical AI architectures, durable materials, novel energy systems, and unique propulsion methods engineered for asteroid or lunar regolith mining will inevitably trickle down to terrestrial Mining Robots, demanding even higher levels of independence than current models (Beyond Humans).

Recycling Revolution: Urban mining – extracting valuable metals from landfills and e-waste – is inefficient and hazardous for humans. Specialized, mobile robotic platforms, guided by sensors to locate specific materials within complex waste streams, will transform this sector, creating circular resource flows with minimal human exposure to toxins.

Beyond Efficiency: The Profound Human and Ethical Implications

The rise of the Mining Robot is about much more than technology. It forces critical considerations:

Workforce Transformation: While eliminating dangerous jobs, it creates new high-tech roles in robot supervision, maintenance, and data analysis. The challenge lies in retraining traditional miners for these positions.

Economic Geography Shifts: Remote mines become more viable when fewer humans need local infrastructure. This could redistribute mining jobs from remote towns to urban control centers.

Environmental Paradox: While robots enable cleaner, more precise extraction, they also make previously uneconomical deposits viable, potentially increasing total extraction.

Security Concerns: Autonomous mining fleets represent high-value targets for cyberattacks, requiring unprecedented security measures.

FAQs: Your Burning Questions About Mining Robots Answered

Q: How much does a Mining Robot cost compared to traditional equipment?

A: While initial costs are higher (20-50% premium for autonomous haul trucks, for example), the total cost of ownership is often lower due to 24/7 operation, reduced maintenance from optimized usage, and elimination of operator costs. Most operations see ROI within 2-3 years.

Q: Can Mining Robots completely replace human miners?

A> Not entirely in the foreseeable future. While they handle dangerous, repetitive tasks, humans remain essential for high-level decision-making, maintenance, and handling exceptions. The workforce composition shifts dramatically rather than disappearing.

Q: What happens when a Mining Robot breaks down underground?

A> Modern systems have multiple redundancy systems. If primary systems fail, backup communications and minimal mobility allow them to reach safe positions. For catastrophic failures, mines have recovery protocols using specialized equipment. Most importantly, no human lives are risked in recovery operations.

The Inevitable Conclusion: Resistance Is Futile

The data is unequivocal: mines adopting Mining Robot technologies achieve 30-50% productivity gains, 70-90% reductions in safety incidents, and 15-30% lower operating costs. As ore grades decline and societal tolerance for mining risks diminishes, autonomous solutions transition from competitive advantage to existential necessity. The question isn't whether robotics will dominate mining's future, but how quickly operations can adapt. Those embracing this transformation will unlock Earth's remaining resources responsibly; those resisting will join the abandoned mines of history. The mineral gold rush of human daring is over; the age of the Mining Robot has begun.