Imagine explorers, not clad in powered armor, but operating robotic limbs of astonishing power and precision, thousands of kilometers away on the surface of a desolate moon. Picture salvage crews retrieving precious interstellar resources from treacherous asteroid fields, guided by human intuition but executed through the unyielding strength of hardened steel actuators. This is not distant science fiction. Space Marine Robot Arms – high-precision, ultra-durable robotic manipulators inspired by terrestrial marine robotics and hardened for the extreme rigors of space – are rapidly evolving from concept to critical infrastructure. Forget delicate lab bots; the future of deep space operations belongs to robotic arms built to military specifications, capable of surviving cosmic radiation, crushing vacuum, micrometeorite bombardment, and brutal thermal extremes. Understanding this convergence of marine robotics legacy, cutting-edge AI, and space-grade engineering is paramount as humanity pushes beyond Earth's cradle. We're building the tools today that will build, repair, and explore the cosmos tomorrow.

Military Muscle Meets Space: The Essence of Space Marine Robot Arms

So, what exactly is a Space Marine Robot Arm? At its core, it's a specialized robotic manipulator system designed for extreme environments, drawing critical inspiration and technology from two demanding frontiers: deep-ocean marine robotics and military-grade engineering. These aren't your standard industrial robotic arms.

Core Design Philosophies: Ruggedization First

Surviving the Void & the Vast: Unlike terrestrial bots, Space Marine Robot Arms must contend with vacuum (requiring special lubrication, seals, and pressure-tolerant designs), extreme temperature swings (-270°C to +120°C in sunlight), intense cosmic radiation degrading electronics, and the relentless micrometeorite threat. Materials like radiation-hardened alloys and specialized composites are non-negotiable.

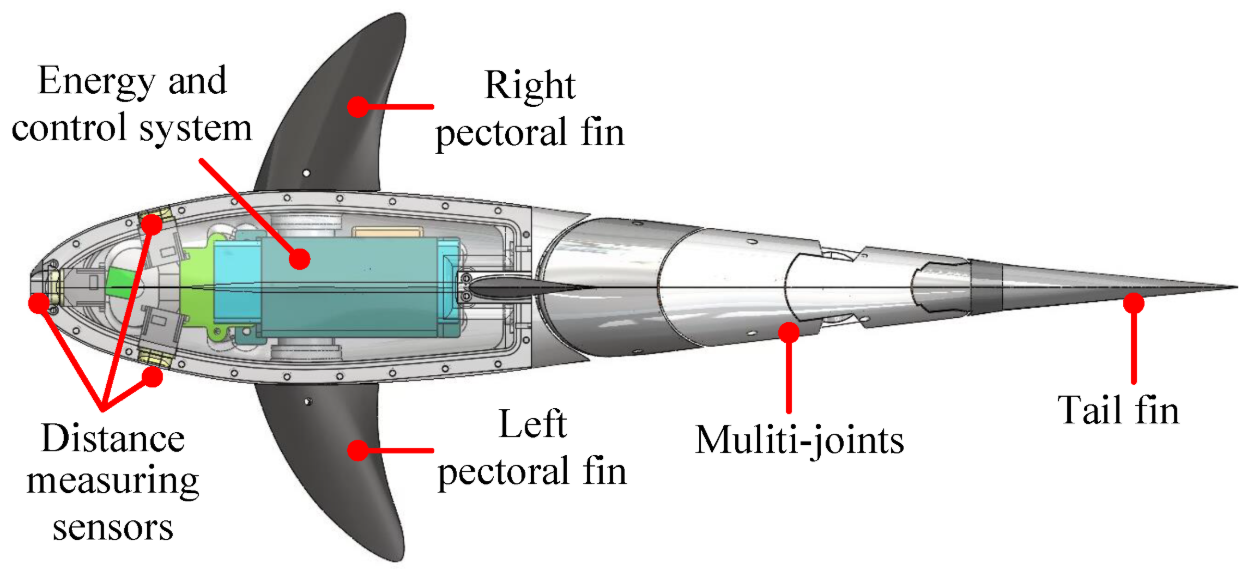

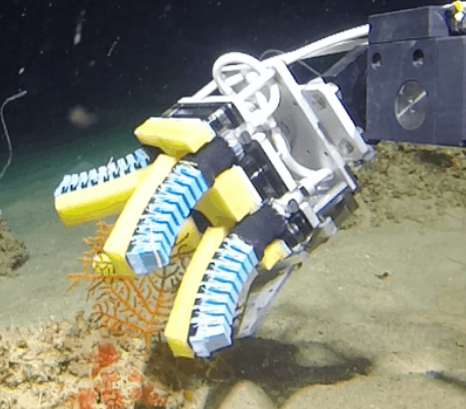

Deep Ocean DNA: Terrestrial marine robots, particularly Remotely Operated Vehicles (ROVs) performing demanding tasks on deep-sea oil rigs or underwater infrastructure, are a primary technological ancestor. Their proven robustness against high pressure, corrosion (swapped for vacuum/radiation challenges), and need for precise teleoperation under harsh conditions directly informs space-ready designs. Techniques perfected for manipulating complex valves and handling heavy loads kilometers underwater are being adapted for manipulating docking ports or asteroid samples in orbit.

Military-Grade Reliability: Where failure is catastrophic, the space environment demands near-perfect reliability. Space Marine Robot Arms incorporate fail-safes, redundancy (multiple motor windings, dual sensors), and built-in diagnostics honed by military applications. They are designed to withstand shocks, vibrations, and stresses exceeding typical mission profiles, ensuring they operate when it counts. This relentless focus on durability under duress is the defining characteristic. Explore how terrestrial marine robot technology prepares us for alien challenges in our companion piece: Marine Robot Interstellar: Earth's Ocean Tech Prepping for Alien Oceans.

The Need for Supreme Dexterity & Strength

It's not just about being tough; it's about being capable. Space Marine Robot Arms must exhibit:

Precision Under Pressure: Manipulating delicate scientific instruments or performing intricate repairs on spacecraft structures requires sub-millimeter control, even with bulky spacesuit gloves in pressurized gloves or through remote teleoperation signals delayed by distance. Advanced force-feedback systems and tremor cancellation algorithms are crucial.

Significant Payload Capacity: These arms must lift, move, and position heavy cargo modules for orbital construction, handle massive ice chunks extracted from celestial bodies, or maneuver large pieces of space debris. This necessitates powerful actuators and rigid structural design, often incorporating harmonic drives for compact, high-torque performance without backlash.

Environmental Dexterity: Whether coated in abrasive moon dust (regolith), operating near searing-hot engine bells, or gripping icy surfaces on Europa, the end-effectors (the "hands") must be adaptable and robust, incorporating specialized tools and sensing capabilities.

Core Challenges Solved: Where Space Marine Robot Arms Dominate

The unique demands of off-world operations create specific niches where Space Marine Robot Arms become indispensable.

Overcoming Astronomical Distance: Teleoperation & AI Autonomy

Human reach in deep space is limited by physics. Light-speed delay makes direct joystick control impossible beyond lunar orbit. Space Marine Robot Arms overcome this through:

Advanced Predictive Teleoperation: Operators on Earth use sophisticated interfaces that predict the robot's state and the effect of commands, mitigating delay effects.

Robust Semi-Autonomy & AI: Space Marine Robot Arms rely heavily on sophisticated AI for task-level autonomy. Imagine instructing an arm to "replace solar panel Z on Module B." The robot's AI decomposes this into hundreds of precise movements: navigating to the location, identifying the correct fasteners, unscrewing them, handling the panel, installing the replacement, and verifying integrity – all while compensating for spacecraft drift and minor obstacles. Machine learning refines these tasks over time. This level of AI integration is the true differentiator from simpler manipulators.

Haptic Feedback & Shared Control: Where feasible, advanced force/torque sensors provide operators with tactile feedback ("feeling" what the robot feels), and AI assists in smoothing motions or preventing collisions (shared control).

Thriving in the Hostile Cosmic Environment

Simply surviving is an engineering triumph:

Radiation Hardening: Electronics and sensitive components use special chips (rad-hard), shielding (like tantalum), and error-correcting memory to survive solar flares and cosmic rays.

Thermal Extremes: Active thermal control systems (heaters and radiators) combined with passive insulation and special thermal coatings are vital. Lubricants must remain effective across massive temperature ranges.

Vacuum Adaptation: Outgassing materials are banned. Lubrication requires space-qualified grease or dry lubrication. Bearings and seals are specially designed to operate without atmosphere, preventing cold welding and contamination.

Micrometeorite & Debris Resistance: Critical components often feature Whipple shielding (layered bumper plates) and are placed strategically behind existing structures where possible. Arm materials are chosen for toughness. Discover how robotic ingenuity tackles harsh environments: Revealed: How Marine Robot Cleaners Are Secretly Saving Our Oceans (terrestrial parallels of resilience).

Performing Critical Operations Remotely

The missions are high-stakes:

On-Orbit Servicing, Assembly & Manufacturing (OSAM): Building massive space telescopes, lunar space stations, or fuel depots requires assembling large structures in microgravity. Space Marine Robot Arms are the heavy lifters and precision technicians.

Planetary & Lunar Surface Operations: Deploying instruments, collecting samples, constructing habitats, maintaining life support systems, and prospecting for resources like water ice are prime tasks for rover-mounted or base-fixed arms.

Space Debris Removal: Safely capturing defunct satellites and hazardous fragments requires precise, robust manipulators – a task perfectly suited for these hardened systems.

Emergency Repairs: Addressing sudden leaks, fixing solar arrays, or clearing critical obstructions often requires immediate intervention – too risky, slow, or impossible for suited astronauts.

The AI Evolution: From Precision Tools to Cognitive Partners

While strength and durability are foundational, the true revolution in Space Marine Robot Arms lies in their intelligence.

Autonomous Task Execution: Beyond Simple Programming

Gone are the days of purely pre-programmed sequences in controlled factories. Space Marine Robot Arms must:

Perceive & Understand: Fuse data from stereo cameras, LIDAR, depth sensors, force/torque sensors, and proximity detectors into a real-time 3D world model. AI interprets this scene, identifying objects, obstacles, surfaces, and their properties.

Plan in Complex Spaces: Given a high-level goal ("Retrieve the core sample tube from Bay 3"), onboard AI plans the optimal sequence of motions, considering kinematics, dynamics, obstacles, power constraints, and safety margins. This planning happens dynamically as the environment changes.

Learn & Adapt: Machine learning algorithms allow the arm to improve its performance. It learns the nuances of its own mechanics (calibration drift compensation), the specific textures and compliance of handled objects, and refines motion strategies based on successful or failed attempts, adapting to wear or minor damage.

Recover from Failure: AI enables autonomous error detection and recovery. If a bolt jams or an expected object isn't found, the system doesn't just halt; it intelligently diagnoses the issue, generates alternative plans, or safely retries using different force profiles or approaches.

Sensing the Subtle: Haptics, Vision, and Spatial Awareness

Achieving superhuman dexterity demands superhuman senses:

Force/Torque Sensitivity: Precise sensing at the wrist and fingers allows the robot to handle delicate objects (like scientific samples) without crushing them, insert components without jamming, and "feel" friction and surface textures.

3D Vision & Depth Perception: Advanced stereo cameras combined with LIDAR or structured light systems create detailed 3D maps of the workspace, enabling precise manipulation even in cluttered or changing environments.

Proprioception & Self-Awareness: The arm constantly monitors its own position, velocity, and torque at every joint, enabling precise control and immediate detection of unexpected contact or resistance.

Frequently Asked Questions

Space Marine Robot Arms are fundamentally different from industrial arms in several key ways. While factory robots operate in controlled environments with consistent temperatures and no vacuum, space-rated arms must withstand extreme thermal swings (-270°C to +120°C), survive in vacuum without lubrication breakdown, and resist radiation that would fry standard electronics. They also incorporate far more redundancy, with dual motor windings, backup sensors, and radiation-hardened processors. The AI systems are more advanced to handle unpredictable environments rather than repetitive, pre-programmed motions.

The operational range depends on the autonomy level. For direct teleoperation (human-in-the-loop control), light-speed delay becomes problematic beyond lunar distances (about 1.28 seconds round-trip). However, Space Marine Robot Arms designed for Mars or asteroid operations use predictive interfaces and semi-autonomous AI that can execute complex tasks with only high-level human oversight. Some experimental systems can operate completely autonomously for weeks or months between human check-ins, making them viable for missions to Jupiter's moons or beyond.

Design lifetimes vary by mission, but current-generation Space Marine Robot Arms are typically rated for 10-15 years of continuous operation without maintenance. This is achieved through: radiation-hardened components that resist degradation, specially formulated lubricants that don't dry out or evaporate in vacuum, redundant systems that can switch to backups if primary systems fail, and smart wear-leveling algorithms that distribute mechanical stress evenly across components. The Canadarm2 on the ISS, for example, has been operating flawlessly since 2001 with only minor software updates.

Conclusion: The Indispensable Cosmic Workforce

As humanity ventures further into the solar system, Space Marine Robot Arms will serve as our mechanical avatars – extending human capability into environments too hostile or distant for biological explorers. Combining military-grade ruggedness with cutting-edge AI, these systems represent the pinnacle of robotic engineering. From constructing orbital habitats to mining asteroids, from repairing satellites to exploring alien oceans, these robotic limbs will be the tools that build humanity's future in space. The lessons learned from deep-sea marine robotics have proven invaluable, but the challenges of space demand even greater innovation. As we stand on the brink of interplanetary civilization, one thing is certain: the robots going with us won't be delicate lab specimens – they'll be hardened Space Marine veterans, built to survive the cosmic frontier.