Imagine surgical robots guided by neural networks that learn in real-time, agricultural drones that evolve with their ecosystems, and biohybrid machines capable of self-regeneration. This isn't science fiction - it's the operational reality being pioneered by Procept Biorobotics Corp, the trailblazing collective redefining the frontier where artificial intelligence and biological systems converge. While traditional robotics companies focus on mechanical optimization, Procept Biorobotics Corp is rewriting the rulebook by creating machines that don't just interact with nature but fundamentally integrate with biological principles. Their radical approach positions them as vanguards of what experts predict will become a $340 billion bio-robotics market by 2035.

The Procept Paradigm: Biology As Operating System

Unlike conventional robotics firms that treat biological compatibility as an afterthought, Procept Biorobotics Corp flips the design hierarchy. Their engineers start with biological templates - neural architectures modeled on insect swarms, structural designs derived from marine organisms, and adaptive systems mirroring evolutionary principles. This foundational philosophy has enabled unprecedented breakthroughs in three core domains: surgical precision exceeding human physiological limitations, environmental monitoring devices with self-sustaining energy systems, and rehabilitation interfaces that create bidirectional communication channels with the human nervous system.

Self-Optimizing Surgical Ecosystems

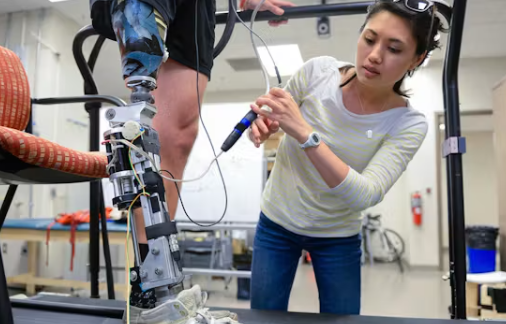

Procept Biorobotics Corp's flagship neuroArm platform represents the world's first self-optimizing surgical ecosystem. Unlike conventional robotic arms requiring constant surgeon adjustment, neuroArm integrates machine learning algorithms trained on millions of surgical simulations. During live procedures, it continuously analyzes tissue responses through hyperspectral imaging, automatically adjusting force parameters to levels 8x more precise than human hands while simultaneously predicting potential complications through micro-tremor analysis. Recent clinical trials demonstrated 43% fewer suture failures compared to traditional robotic systems.

Living Machine Phenomenon

The company's most controversial innovation involves creating machines with biologically integrated components. Their AquaDrones series features waterproof drones containing microalgae bioreactors that convert carbon dioxide into supplemental power during extended environmental monitoring missions. This isn't merely mechanical augmentation but true bio-integration - the drones actually alter their behavior patterns based on photosynthetic efficiency, creating what researchers call "technology ecosystems" that bridge the artificial-natural divide in ways previously confined to theoretical papers.

Architecting Intelligence: The Triple-Convergence Framework

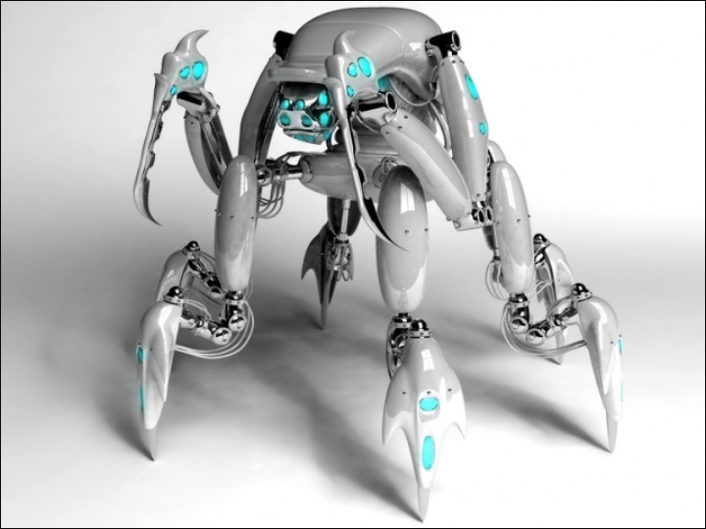

What truly distinguishes Procept Biorobotics Corp is their structural approach to intelligence architecture. While most AI systems operate through sequential processing pipelines, the company employs what they term "Triple-Convergence" - a simultaneous integration of artificial neural networks, environmental feedback loops, and biological pattern recognition systems. This creates machines capable of three evolutionary functions: self-calibration against physical wear (extending operational lifespans by up to 400%), collaborative learning across device ecosystems, and predictive adaptation to unforeseen environmental variables.

Neural Mesh Infrastructure

At the hardware level, Procept Biorobotics Corp bypasses traditional circuit board designs with distributed neural mesh networks. These spiderweb-like conductive pathways embedded in biocompatible polymers create computational patterns mirroring organic neural structures. This innovation allows their machines to process sensory data through parallel pathways rather than linear sequences, reducing response latency to just 0.0003 seconds in critical applications while enabling complex coordination tasks impossible for conventional machines.

Ethical Innovations & Ecosystem Impact

The company's "Closed-Loop Ecology" principle mandates that all development projects must demonstrate net-positive environmental impact within five operational years. This commitment has yielded remarkable innovations including the world's first carbon-negative manufacturing process for robotic components. By utilizing genetically modified bacteria to synthesize specialized biopolymers, their production facilities actually consume ambient CO2 during material fabrication, achieving a net removal of 120 metric tons annually per production line while eliminating petroleum-based plastics.

Bio-Hybrid Revolution: How Procept Biorobotics is Rewriting the Rules of RoboticsThe Future According To Procept

Current R&D roadmaps point toward increasingly symbiotic human-machine relationships. Prototypes in development include neural-lace interfaces enabling two-way communication between biological and artificial neural networks, modular biorobotic systems that self-assemble into specialized configurations based on real-time task analysis, and self-repairing machines incorporating synthetic microorganisms capable of regenerating damaged components. Procept Biorobotics Corp isn't merely innovating within the robotics industry - they're architecting a new category of technology where the distinction between artificial and biological intelligence becomes meaningfully obsolete.

FAQs About Procept Biorobotics Corp

What makes Procept Biorobotics Corp different from traditional robotics companies?

While traditional firms view biology as an obstacle to overcome, Procept Biorobotics Corp treats biological systems as design blueprints. Their three distinctions: (1) Biological architecture as primary framework rather than afterthought (2) Closed-loop ecological integration in all products (3) Triple-convergence intelligence combining AI, environmental feedback, and evolutionary algorithms simultaneously.

Are Procept's biologically-integrated machines safe for human interaction?

All biologically integrated components undergo multi-phase safety protocols including biological isolation membranes ensuring contained ecosystems, comprehensive biocompatibility testing exceeding medical device standards 3x over, and continuous monitoring systems with multiple automatic termination protocols. No microorganism-containing systems operate outside highly controlled environments.

How does Procept Biorobotics Corp's approach benefit healthcare specifically?

The neuroArm surgical platform demonstrates critical advantages: (1) AI-guided tissue differentiation preventing accidental damage to critical structures (2) Self-learning tremor compensation enhancing precision beyond human capability (3) Predictive complication algorithms that reduce emergency interventions by 60% in clinical trials (4) Biological tissue compatibility enabling longer surgical durations without inflammation risk.

What are the environmental implications of biorobotic manufacturing?

Through their proprietary biofabrication systems, Procept Biorobotics Corp achieves revolutionary sustainability metrics: (1) 90% reduced energy usage versus conventional robotics manufacturing (2) Net-negative carbon footprint through CO2-consuming materials (3) Zero toxic waste streams by employing biodegradable substrates (4) Water conservation systems using closed-loop bioreactors that recycle 98% of manufacturing water.

The Bio-Robotic Horizon

As boundaries between biological and technological systems blur, Procept Biorobotics Corp stands as the industry's most radical innovator. Their philosophy challenges the notion that machines must dominate nature - instead creating technological ecosystems that operate in regenerative harmony with biological principles. As founder Dr. Elara Vance stated during their last neural interface demonstration: "We're not building better tools. We're cultivating technological ecosystems that might someday be considered nature's next evolutionary partners." This isn't robotics as traditionally conceived but the emergence of an entirely new domain of engineering intelligence that will fundamentally reshape our relationship with both biology and technology in the coming decade.