Imagine a world where the vast oceans become an unlimited source of clean energy. Thanks to groundbreaking AI hydrogen catalyst technology, scientists are cracking the code to efficiently produce hydrogen from seawater—a game-changer for sustainable energy. This article dives into how AI is supercharging catalyst design, slashing costs, and paving the way for a greener future. Buckle up! ??

The Big Problem: Why Seawater Hydrogen Matters

Hydrogen fuel is hailed as the holy grail of clean energy, but traditional methods guzzle freshwater—a scarce resource. Enter seawater: covering 71% of Earth’s surface, it’s the ultimate untapped reservoir. But here’s the catch: seawater is salty, corrosive, and packed with impurities that wreck electrolysis equipment. Traditional systems struggle with efficiency and cost, but AI hydrogen catalyst tech is flipping the script.

How AI is Revolutionizing Catalyst Design

AI hydrogen catalyst technology isn’t just about smarter algorithms—it’s about reimagining materials at the atomic level. Here’s how it works:

Accelerated Catalyst Discovery

AI models like DeepMind’s AlphaFold predict molecular structures that boost electrolysis efficiency. For example, researchers recently used machine learning to design a nickel-iron catalyst that cuts energy use by 30% compared to platinum .Real-Time Electrolysis Optimization

AI systems analyze data from sensors to tweak voltage, temperature, and pressure on the fly. This prevents salt buildup and extends equipment lifespan—a game-changer for offshore hydrogen farms .Material Screening at Warp Speed

Traditional catalyst testing takes years. AI? It simulates thousands of compounds in hours. A 2024 study showed AI-optimized cobalt-based catalysts achieved 12.6% solar-to-hydrogen efficiency using seawater .

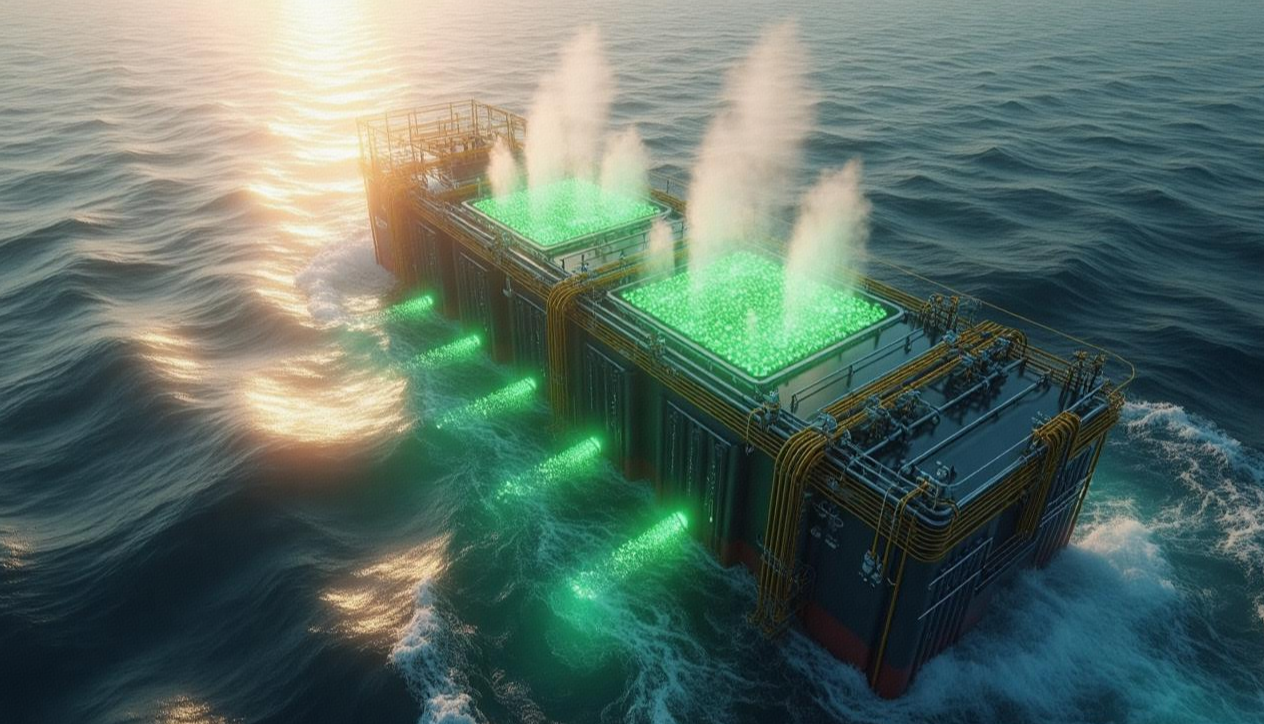

Case Study: China’s Floating Hydrogen Factory

Sinopec’s Qingdao Refinery project is a prime example of AI hydrogen catalyst tech in action. By integrating AI with PEM electrolyzers, they:

Reduced chlorine corrosion by 90% using smart anode coatings .

Achieved 20 cubic meters/hour of green hydrogen using offshore wind power.

Slashed operational costs by 25% through predictive maintenance algorithms .

5 Steps to Build Your Own AI-Powered Seawater Reactor

(Spoiler: You’ll need a lab and some coding skills!)

Source Seawater

Collect samples from coastal areas (avoid polluted zones). Test salinity and pH—ideal levels are 3% salt and 7–8 pH.Choose Your Catalyst

Start with AI-recommended materials like NiFe-LDH (nickel-iron layered double hydroxide) or IrO? nanoparticles.Set Up Electrolysis Cells

Use modular stacks with titanium mesh electrodes. Install IoT sensors for real-time monitoring.Train Your AI Model

Feed data on current density, gas output, and impurities into platforms like TensorFlow or PyTorch.Scale and Optimize

Deploy in small offshore units first. Use reinforcement learning to adjust parameters for max efficiency.

Top 3 Tools for AI Hydrogen Catalyst Development

DeepMind’s AlphaFold

Predicts protein-like catalyst structures for biohybrid systems.AutoDesk Fusion 360

Designs 3D-printed reactor cores optimized for saltwater resistance.Hugging Face ML Models

Open-source libraries for electrolysis process simulation.

The Challenges Ahead

While AI hydrogen catalyst tech is explosive, hurdles remain:

Corrosion Woes: Saltwater eats metal components. Solution? Nano-coatings like graphene oxide .

Energy Balance: Solar-powered desalination + electrolysis needs 12% efficiency to break even .

Cost: Iridium-free catalysts are 95% cheaper but still require scale-up .

Future Outlook: Blue Hydrogen Oceans

By 2030, expect:

Offshore Hydrogen Farms: Floating platforms powered by wind + AI catalysts.

Hydrogen-Aviation: Zero-emission planes fuelled by seawater.

Global Standards: The IMO’s new guidelines for marine hydrogen systems .