Understanding the Core Functionality of a Baking Robot

At its essence, a Baking Robot is a specialized automated machine designed to perform one or multiple tasks in the baking process. Unlike a general-purpose robot, these systems are engineered with specific functions in mind, such as mixing, shaping, dispensing, or decorating. They integrate advanced technologies like AI for vision recognition, machine learning for process optimization, and precise actuators for delicate tasks. The primary goal is to augment human labor by taking over repetitive, strenuous, or highly precise operations, thereby increasing output, ensuring unwavering consistency, and improving overall hygiene by minimizing human contact with food products.

A Detailed Breakdown of Baking Robot Types by Application

The world of bakery automation is diverse. To truly understand it, we must categorize these machines by their primary function within the production line. Each type represents a unique solution to a specific challenge in the baking industry.

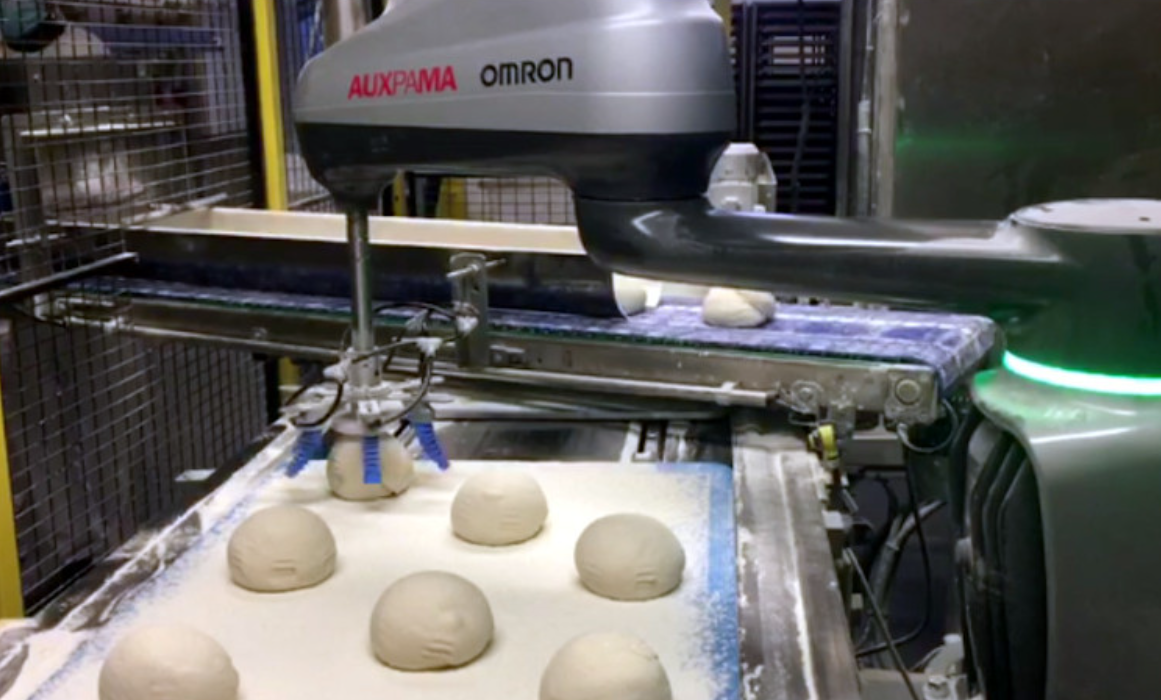

1. Dough Preparation and Handling Robots

This category includes the workhorses of the bakery, the robots that deal with the raw, unbaked product. They are built for strength, consistency, and hygiene. A prime example is the automated dough divider and rounder. These systems can accept a large bulk of dough, precisely weigh and divide it into portions of exact mass, and then gently shape those portions into perfect balls without tearing the gluten structure. This consistency is nearly impossible to maintain manually over a long shift. Other robots in this category include automated mixers that can be programmed for specific sequences and speeds, and dough sheeters that prepare dough for pastries like croissants and puff pastry.

2. Decoration and Icing Baking Robot Systems

Where dough handlers are about brute force and precision, decorator robots are about artistry and delicacy. These are often multi-axis articulated arms equipped with a specialized dispensing tool. Using high-resolution vision systems, they can identify the position and orientation of a cake, cookie, or pastry. They are then programmed to apply intricate patterns, write text, or layer frosting with millimeter accuracy. The same robot can store hundreds of different designs, switching between them instantly, allowing for mass customization where every product can be unique without slowing down the production line.

3. Oven Loading and Unloading Automation

This is a critical yet often overlooked application. Transporting delicate, proofed dough into a scorching hot oven is a risky task that can lead to product loss if done incorrectly. Automated oven loader robots solve this problem. Using gentle suction grippers or custom-designed fingers, they can carefully pick up trays of proofed bread and place them seamlessly into the oven. Similarly, on the other end, unloader robots can extract finished products, sorting them based on pre-defined criteria like color (using vision systems) to ensure perfect baking every time. This automation also creates a safer work environment by removing humans from extreme heat.

4. Packaging and Palletizing Baking Robot Units

Once the baking and cooling are complete, the final products must be prepared for shipment. Packaging robots can gently pick up fragile items like bread loaves or delicate pastries and place them into bags, boxes, or clamshells. These robots are often paired with vision systems to ensure correct orientation and labeling. Palletizing robots then take these packaged goods and stack them neatly onto pallets for distribution. These robots are incredibly strong and can optimize stacking patterns to maximize stability and space utilization during transport, reducing costs and damage.

Specialized Baking Robot Variants for Niche Markets

Beyond the broad categories, some robots are designed for hyper-specific tasks that define certain products. For instance, a pretzel-twisting robot can mimic the complex manual motion needed to shape a pretzel at incredible speeds. Similarly, there are robots dedicated solely to filling doughnuts with jam or cream, injecting precisely the right amount of filling into the exact center every single time. Another niche variant is the pizza sauce spreader, which can apply a perfectly even layer of sauce onto a pizza base in a circular motion faster than any human. These specialized machines highlight the depth of innovation aimed at automating even the most traditionally manual skills.

The Intelligence Behind the Arm: AI's Role in Modern Baking Robot Systems

It's a mistake to view these machines as simple pre-programmed arms. The latest generation of Baking Robots are intelligent. They employ AI and machine learning for adaptive control. For example, a vision system can inspect each raw cookie dough portion for size and shape deviations and instruct the robot to adjust its decoration pattern accordingly to ensure the final product still looks perfect. Machine learning algorithms can also analyze data from the baking process itself, learning to optimize oven temperatures and timings based on ambient humidity and flour batch variations, pushing automation beyond mere physical tasks into the realm of quality control and process optimization.

Frequently Asked Questions About Baking Robots

What is the average cost of implementing a Baking Robot?

The cost can vary dramatically based on the type and complexity of the system. A single-task robot arm might start in the tens of thousands of dollars, while a fully integrated, custom-built automated production line can run into the millions. However, the ROI is calculated based on increased output, reduced waste, lower labor costs, and improved consistency, often making the investment worthwhile for medium to large-scale operations.

Can Baking Robots completely replace human bakers?

No, and that is not the goal. The current technology is best suited for repetitive, scale-driven tasks. The creativity, recipe development, and nuanced judgment of a master baker remain irreplaceable. The ideal scenario is collaboration, where robots handle the bulk, repetitive work, freeing up skilled bakers to focus on innovation, quality control, and crafting artisanal products.

How do Baking Robots handle food safety and hygiene?

Hygiene is a primary design feature. Most Baking Robots are constructed with food-grade stainless steel and materials that are easy to clean and sanitize. Their design often minimizes crevices where debris can accumulate. Furthermore, by reducing direct human contact with the product, they significantly lower the risk of contamination, making them a powerful tool for complying with stringent food safety standards like HACCP and SQF.

What training is required to operate a Baking Robot?

Modern Baking Robots are designed with user-friendly interfaces that require minimal specialized training. Most manufacturers provide comprehensive training programs that can typically be completed in a few days to a week. The focus is on programming, maintenance, and troubleshooting rather than complex robotics engineering, making them accessible to bakery staff with basic technical skills.

The evolution of Baking Robots represents more than just automation; it signifies a fundamental transformation in how we approach the ancient craft of baking. From precise dough handling to artistic decoration, these machines are expanding the possibilities of what bakeries can achieve in terms of scale, consistency, and creativity. As technology continues to advance, we can expect to see even more sophisticated systems that further blur the line between automated efficiency and artisanal quality, ultimately creating a future where technology and tradition work in harmony to produce the baked goods we love.