Imagine a world where the delicate, buttery layers of a perfect croissant are crafted not by human hands alone, but with the meticulous precision of artificial intelligence. This is not a scene from a sci-fi movie; it is the present and future being pioneered by the innovative Dominique Ansel Bakery Robot. This groundbreaking project represents a seismic shift in the culinary landscape, merging the soul of a world-renowned pastry chef with the relentless accuracy of robotics. This article delves deep into how this fusion is redefining creativity, consistency, and the very essence of gourmet baking, offering a unique glimpse into a future where human artistry and machine perfection coexist.

Who is Dominique Ansel and Why a Bakery Robot?

Before understanding the robot, one must appreciate the artist behind it. Dominique Ansel is the acclaimed pastry chef and inventor of the global sensation, the Cronut?—a croissant-doughnut hybrid that sparked hours-long queues and a culinary revolution. His philosophy has always been rooted in innovation, creativity, and an unwavering commitment to quality. For Chef Ansel, the drive to explore the Dominique Ansel Bakery Robot stems from a desire to push boundaries beyond human limitations. The goal was never to replace the baker but to create a tool that could extend the baker's capabilities, executing incredibly complex and repetitive tasks with superhuman precision, thereby freeing up time for even more creative exploration.

Deconstructing the Dominique Ansel Bakery Robot: How It Works

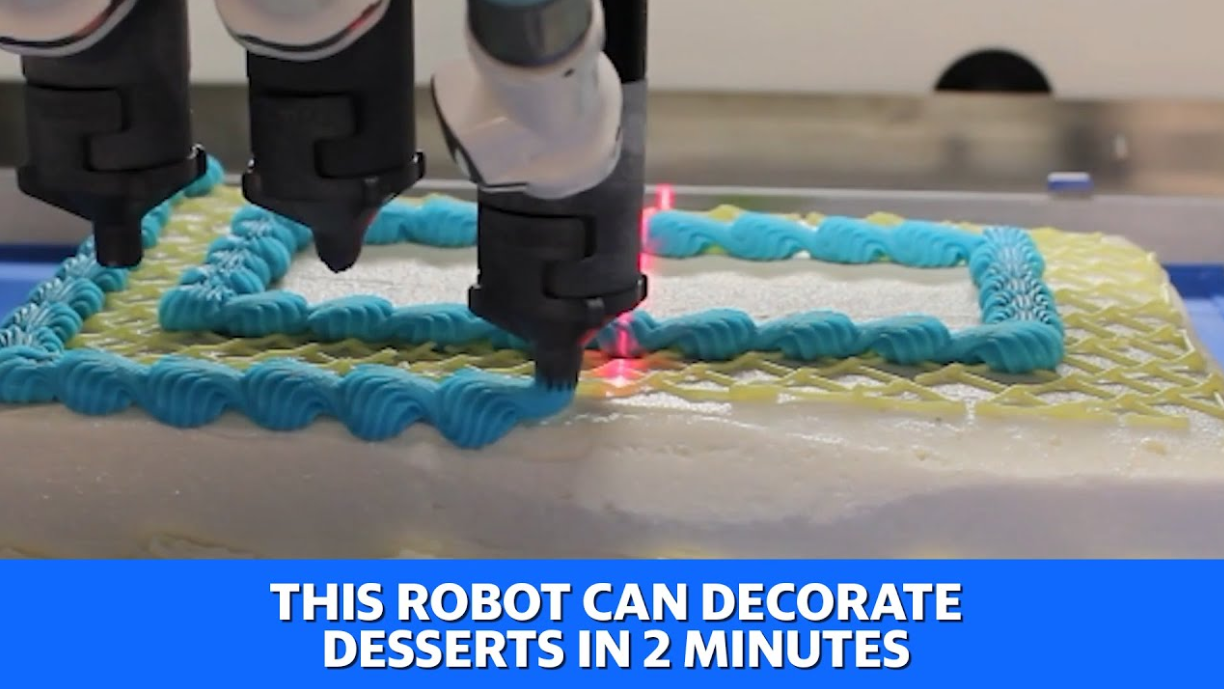

The Dominique Ansel Bakery Robot is a marvel of engineering and culinary science. It is far more than a simple automated arm; it is a integrated system powered by advanced AI and machine learning algorithms. At its core, the system utilizes high-resolution 3D vision cameras to analyze raw ingredients, much like a human baker assessing the quality of butter or the elasticity of dough. The AI then cross-references this data against a vast digital library of Ansel's recipes and techniques. Using this information, robotic actuators precisely measure, mix, fold, and shape pastries. The system can adjust in real-time to variables like ambient temperature and humidity, ensuring every single item produced meets an exacting gold standard of quality that is impossible to maintain manually at scale. This pursuit of perfection is part of a broader movement, as seen in The Robotic Revolution in Baking.

The Technology Stack: AI, Vision Systems, and Precision Actuators

The technological heart of the operation involves a synergy of several cutting-edge components. The AI is trained on thousands of data points from Chef Ansel's own movements and decisions, effectively learning his "signature" style. The vision systems ensure that every fold of laminated dough has the correct number of layers and that the color of a baking product is exactly right. The precision actuators can handle delicate tasks, from piping exact amounts of filling to applying delicate sugar decorations, all with zero deviation. This eliminates human error and variability, guaranteeing that the tenth thousandth croissant is identical to the very first one.

The Human-Machine Collaboration: Enhancing, Not Replacing, Creativity

A common fear surrounding automation is the erosion of artistry. The Dominique Ansel Bakery Robot project flips this narrative on its head. Instead of replacing the pastry chef, the robot acts as the ultimate sous-chef. It handles the tedious, physically demanding, and precision-critical tasks—such as the laminating of dough for viennoiserie, which requires consistent temperature control and exact rolling. This liberation of time and mental energy allows Chef Ansel and his team to focus on what humans do best: creative ideation, flavor development, and personal interaction. The robot becomes a tool for amplification, enabling the creation of pastries that were previously too complex or time-consuming to produce consistently by hand.

Unique Angles: Perspectives You Haven't Read Elsewhere

While many articles focus on the "robot making food," our unique angle explores the philosophical implications of this collaboration. The Dominique Ansel Bakery Robot is not about efficiency for profit; it's about the preservation and dissemination of craft. It raises a fascinating question: Can a machine learn the "soul" of a recipe? Ansel's project suggests it can codify the technique, allowing a master's skills to be replicated and preserved with perfect fidelity long into the future. Furthermore, it democratizes access to world-class pastries, ensuring that no matter where in the world a bakery utilizes this technology, the product will be unmistakably and perfectly "Ansel." This consistency builds immense brand trust and value.

Addressing the Skeptics: Artisanal Quality in the Age of Automation

Skeptics argue that machine-made food lacks a "soul." However, this project compellingly argues that soul resides in the initial creativity and recipe design—the human domain. The robot's role is to protect the integrity of that vision every single time it is executed. In this context, the machine becomes the guardian of artisanal quality, ensuring that every customer experiences the product exactly as the creator intended, a feat often challenged by human fatigue and natural variance.

Frequently Asked Questions (FAQs)

Can the Dominique Ansel Bakery Robot create new recipes?

No, the current iteration of the robot is designed for replication and precision execution. It operates based on a pre-loaded library of recipes and techniques developed by Chef Ansel. The creativity and invention of new pastries remain a firmly human endeavor. The robot serves to bring those new ideas to life with flawless consistency once they are created.

Where is the Dominique Ansel Bakery Robot being used?

The technology is primarily deployed in Dominique Ansel's flagship locations as a proof-of-concept and to ensure ultimate quality control. The long-term vision likely involves scaling this technology to maintain quality across future international expansions, ensuring a signature experience in every global outlet.

Does this automation mean fewer jobs for bakers?

This is a nuanced issue. While the robot may reduce the number of repetitive, manual labor positions, it simultaneously creates new, high-skilled jobs in robotics maintenance, programming, and system supervision. Furthermore, by ensuring business growth and scalability, it can lead to net job creation in management, customer service, and creative roles within a larger, more successful enterprise.

How does the robot handle the most delicate tasks without damaging the product?

The robot is equipped with force-feedback sensors and torque-controlled actuators. This means it can "feel" the resistance of the dough or the fragility of a delicate decoration and adjust the amount of pressure it applies instantly, mimicking the sensitive touch of a skilled pastry chef.

The Future of Gastronomy: What This Means for the Industry

The Dominique Ansel Bakery Robot is a pioneering beacon for the entire food and beverage industry. It proves that high-end gastronomy and cutting-edge technology are not mutually exclusive but are, in fact, powerful allies. This sets a precedent for other chefs and bakeries to explore how automation can enhance their craft. We can anticipate a future where personalized nutrition, hyper-consistent quality, and previously unimaginable culinary creations become the norm, all thanks to the collaborative power of human chefs and their AI-powered assistants. The journey has just begun, and the potential is as limitless as our imagination.