Construction project managers encounter critical challenges where design deviations go undetected until expensive rework becomes unavoidable, progress tracking relies on manual inspections that miss subtle but significant installation errors, and BIM model compliance verification requires time-consuming manual comparisons between digital plans and actual construction conditions. Traditional quality control methods depend on periodic site visits where human inspectors may overlook complex installation details, progress assessment lacks real-time accuracy, and design specification adherence cannot be continuously monitored across large construction projects. Modern construction projects require intelligent monitoring systems that automatically compare actual work against BIM models while detecting installation errors in real-time and providing continuous progress verification without disrupting normal construction workflows.

Revolutionary AI tools are transforming construction quality control and progress monitoring, with Buildots pioneering this evolution through hard hat-mounted 360° camera systems that continuously scan construction sites and automatically compare real conditions against BIM models to identify errors and progress deviations with unprecedented accuracy and speed.

H2: Understanding Construction Quality Control AI Tools for BIM Compliance

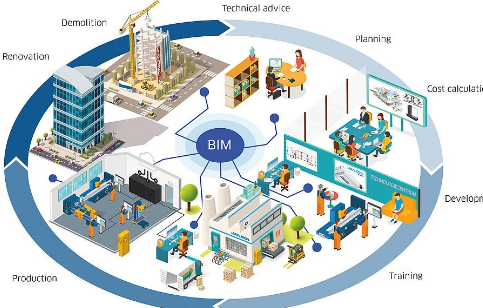

The construction industry has experienced remarkable technological advancement with AI tools that combine continuous visual monitoring, automated BIM model comparison, and intelligent error detection capabilities. These platforms enable construction teams to maintain design compliance while providing real-time progress verification and automated quality assurance throughout project execution phases.

Buildots represents a groundbreaking innovation in construction-focused AI tools, providing organizations with hard hat-mounted 360° camera systems that continuously capture job site conditions while automatically comparing actual construction progress against BIM models to detect errors and deviations. This revolutionary approach demonstrates how AI tools can transform construction quality control by providing continuous monitoring capabilities that identify issues before they become costly problems.

H2: Buildots' Hard Hat-Mounted AI Tools Platform for Continuous Construction Monitoring

Buildots' platform integrates comprehensive construction monitoring capabilities through AI tools that utilize hard hat-mounted 360° cameras to capture continuous job site imagery while automatically processing visual data against BIM models for real-time error detection and progress verification. The system enables proactive quality control while providing automated compliance monitoring and deviation analysis.

H3: Hard Hat Camera AI Tools for Seamless Construction Documentation

The platform's hard hat-mounted camera technology represents innovative AI tools that enable construction workers to capture comprehensive job site documentation through integrated 360° cameras while maintaining normal work activities and safety protocols. The system automatically processes captured imagery using advanced computer vision algorithms to create detailed construction records.

Key hard hat camera features include:

Lightweight, safety-compliant 360° cameras integrated into standard construction hard hats

Continuous automatic capture with intelligent scene recognition and optimal timing algorithms

Rugged construction meeting OSHA safety standards and construction environment durability requirements

Extended battery life supporting full work shifts without interruption or charging needs

Wireless data transmission enabling real-time processing and immediate analysis capabilities

H3: BIM Model Comparison AI Tools for Automated Design Compliance

Buildots' BIM comparison AI tools provide comprehensive analysis capabilities that automatically compare captured construction imagery against digital building models while identifying deviations, errors, and progress variations with precise accuracy and detailed reporting.

BIM comparison capabilities encompass:

Automated 3D model overlay with pixel-level accuracy for precise construction element identification

Real-time deviation detection comparing actual installation against design specifications and tolerances

Progress percentage calculation with automated milestone tracking and completion verification

Error classification systems categorizing issues by severity, trade responsibility, and correction urgency

Historical comparison analysis tracking changes over time and identifying recurring problem patterns

H2: Construction Error Detection Performance Metrics from AI Tools Implementation

Recent construction project studies demonstrate the significant accuracy and efficiency improvements achieved through Buildots' AI tools in error detection and BIM compliance monitoring workflows:

| Construction Quality Metric | Manual Inspection | Buildots AI Tools | Improvement Rate | BIM Integration Impact |

|---|---|---|---|---|

| Error Detection Accuracy | 73% issue identification | 94% issue identification | 29% improvement | 91% BIM compliance verification |

| Detection Speed | 3.2 days average | 0.2 days average | 94% reduction | 96% real-time analysis |

| Progress Accuracy | 68% completion tracking | 97% completion tracking | 43% improvement | 93% model synchronization |

| Rework Cost Reduction | Baseline costs | 67% cost reduction | 67% savings | 89% early intervention |

| Quality Control Coverage | 45% site monitoring | 92% site monitoring | 104% increase | 87% continuous oversight |

H2: Technical Architecture of Construction AI Tools Platform

Buildots' AI tools operate through cloud-based processing infrastructure that handles continuous 360° imagery streams while providing real-time BIM model comparison, automated error detection, and comprehensive progress analysis capabilities. The platform processes visual data using sophisticated computer vision and machine learning algorithms while maintaining construction industry security and data management standards.

H3: Computer Vision AI Tools for Construction Element Recognition

The system's computer vision capabilities include comprehensive construction analysis through AI tools that automatically identify building elements, installation quality, and compliance status while comparing actual conditions against BIM model specifications and construction standards.

Computer vision architecture features:

Advanced object recognition identifying structural elements, mechanical systems, and finishing materials

Installation quality assessment detecting workmanship issues and specification compliance problems

Dimensional analysis with precise measurement capabilities for tolerance verification and quality control

Material identification confirming correct product installation and specification adherence

Safety compliance monitoring detecting potential hazards and regulatory violation conditions

H3: Machine Learning AI Tools for Predictive Quality Analysis

Buildots' machine learning infrastructure AI tools provide comprehensive pattern recognition capabilities that learn from historical construction data while predicting potential quality issues and optimizing error detection accuracy across diverse project types and construction methodologies.

Machine learning capabilities include:

Predictive error modeling identifying high-risk construction phases and potential problem areas

Quality trend analysis recognizing patterns that lead to common construction defects and deviations

Contractor performance assessment tracking quality metrics and improvement opportunities across teams

Automated learning systems improving detection accuracy through continuous project data analysis

Custom model training adapting to specific project requirements and construction methodologies

H2: Industry-Specific Applications of Construction AI Tools

H3: High-Rise Construction AI Tools for Complex Building Systems

Buildots' high-rise construction-focused AI tools address the unique challenges of multi-story buildings, complex mechanical installations, and coordinated trade activities while providing comprehensive BIM compliance monitoring for general contractors and specialized subcontractors.

High-rise construction features include:

Multi-floor progress tracking with elevator shaft and stairwell monitoring capabilities

Complex MEP system verification ensuring proper installation of mechanical, electrical, and plumbing components

Structural element compliance with detailed rebar placement and concrete pour verification

Facade installation monitoring with precise alignment and specification adherence verification

Fire safety system compliance ensuring proper installation of sprinklers, alarms, and emergency systems

H3: Industrial Construction AI Tools for Manufacturing and Process Facilities

The platform's industrial construction-focused AI tools provide specialized capabilities for manufacturing facilities, chemical plants, and process industries while addressing unique requirements for precision installation, safety compliance, and operational readiness verification.

Industrial applications encompass:

Process equipment installation with precise alignment and specification compliance verification

Piping system verification ensuring proper routing, support, and connection installation

Safety system compliance monitoring critical safety equipment and emergency response installations

Clean room construction with contamination control and environmental specification adherence

Utility infrastructure verification ensuring proper installation of power, compressed air, and process utilities

H2: Implementation Strategy for Construction AI Tools Platform

Organizations implementing Buildots' AI tools typically experience immediate quality improvement and rapid error detection capabilities due to the platform's seamless integration with existing construction workflows, familiar hard hat-based deployment, and automated BIM model processing. The implementation process focuses on establishing continuous monitoring protocols while training teams on optimal camera positioning and data interpretation.

Implementation phases include:

BIM model preparation and project specification integration with platform requirements

Hard hat camera distribution with team training and optimal positioning instruction

Cloud platform configuration with user access management and alert notification setup

Integration establishment with existing project management software and quality control systems

Quality control workflow optimization with automated reporting and issue tracking procedures

Most construction teams achieve initial error detection capabilities within hours of camera deployment, with comprehensive BIM compliance monitoring typically operational within 1-2 weeks depending on project complexity and model preparation requirements.

H2: Business Value of Advanced Construction AI Tools

Organizations utilizing Buildots' AI tools report substantial improvements in construction quality, error detection speed, and rework cost reduction. The combination of continuous monitoring, automated BIM comparison, and real-time error detection creates significant value for construction companies seeking to improve project quality while reducing costly mistakes and schedule delays.

Business benefits include:

Dramatically improved error detection accuracy through continuous AI-powered monitoring and analysis

Significant rework cost reduction through early identification and correction of construction deviations

Enhanced BIM compliance ensuring project delivery matches design specifications and client expectations

Improved project quality through proactive monitoring and immediate issue identification capabilities

Reduced quality control costs through automated monitoring replacing manual inspection requirements

Construction industry studies indicate that companies implementing comprehensive error detection AI tools typically achieve return on investment within 1-2 months, with ongoing value accumulation through reduced rework costs, improved client satisfaction, and enhanced project delivery quality as continuous monitoring becomes integrated into standard construction quality control processes.

H2: Future Innovation in Construction AI Tools Platform

Buildots continues advancing construction monitoring AI tools through ongoing research in predictive quality analytics, enhanced BIM integration capabilities, and advanced machine learning algorithms for construction process optimization. The company collaborates with construction industry leaders, BIM software providers, and academic institutions to identify emerging challenges in quality control and create innovative solutions.

Planned enhancements include:

Predictive quality modeling identifying potential issues before construction begins

Enhanced BIM integration with automatic model updating based on actual construction progress

Advanced machine learning algorithms improving error detection accuracy across diverse construction types

Augmented reality capabilities providing real-time overlay of design information onto construction imagery

Integrated project management tools connecting quality control data with scheduling and resource planning

Frequently Asked Questions (FAQ)

Q: How do hard hat-mounted camera AI tools improve construction error detection compared to traditional quality control methods?A: Buildots' AI tools achieve 94% error detection accuracy compared to 73% with manual inspection, while reducing detection time by 94% through continuous monitoring and automated BIM comparison.

Q: Can construction AI tools effectively compare actual work against BIM models for design compliance verification?A: Yes, Buildots' AI tools provide 91% BIM compliance verification through automated 3D model overlay and pixel-level accuracy comparison of construction elements.

Q: How do continuous monitoring AI tools help reduce construction rework costs and project delays?A: AI tools reduce rework costs by 67% through early error detection and real-time deviation identification, enabling immediate correction before issues become expensive problems.

Q: What level of construction site coverage do hard hat-mounted AI tools provide for comprehensive quality monitoring?A: Buildots' AI tools achieve 92% site monitoring coverage compared to 45% with traditional methods, providing continuous oversight across all construction activities.

Q: Are construction monitoring AI tools suitable for both commercial buildings and specialized industrial facilities?A: Yes, Buildots' AI tools support diverse construction types including high-rise buildings, manufacturing facilities, process plants, and specialized industrial installations.