Are you managing industrial operations in hazardous environments while struggling to maintain worker safety standards, execute complex tasks in unstructured spaces efficiently, and enhance operational capabilities despite facing dangerous working conditions that put human workers at risk and limit productivity potential through traditional manual approaches that cannot adapt to dynamic industrial challenges?

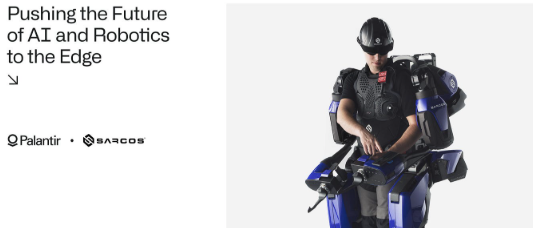

Traditional industrial automation relies on fixed robotic systems, limited environmental adaptability, and human exposure to dangerous conditions that fail to provide flexible task execution, intelligent environmental navigation, and comprehensive safety enhancement that could dramatically improve operational efficiency while protecting human workers from hazardous situations. Manufacturing companies, industrial operators, and safety managers need intelligent robotic solutions that automatically navigate unstructured environments, execute complex manipulation tasks, and provide human capability augmentation that optimizes industrial performance while ensuring worker safety and operational flexibility. This comprehensive analysis explores how revolutionary AI tools are transforming industrial robotics through intelligent automation and human-robot collaboration, with Sarcos Technology leading this innovation in mobile robotics and industrial safety enhancement strategies.

H2: Intelligent AI Tools Revolutionizing Industrial Robotics and Human-Robot Collaboration Systems

Advanced AI tools have fundamentally transformed industrial robotics by creating comprehensive automation frameworks that enable mobile robot systems to navigate unstructured environments while executing complex manipulation tasks through systematic integration of artificial intelligence, advanced sensors, and human-robot collaboration protocols that provide enhanced operational capabilities and safety improvements across diverse industrial applications. These intelligent systems employ machine learning algorithms, environmental perception technology, and adaptive control systems to transform traditional industrial automation approaches into flexible robotic solutions that augment human capabilities rather than replacing human workers. Unlike conventional industrial robots that operate in controlled environments with predetermined tasks, contemporary AI tools provide adaptive automation capabilities that automatically adjust to changing conditions while offering collaborative solutions for optimizing industrial performance and worker safety across complex operational environments.

The integration of artificial intelligence with mobile robotics enables these AI tools to bridge the gap between automated efficiency and human expertise while providing comprehensive solutions that support effective industrial operations and safety enhancement across hazardous work environments and complex task requirements.

H2: Sarcos Technology Platform: Comprehensive AI Tools for Mobile Robotics and Industrial Automation

Sarcos Technology has developed an industry-leading robotics platform that transforms traditional industrial operations using intelligent tools to enable companies to deploy highly dexterous mobile robot systems while leveraging AI-powered automation for executing complex tasks, enhancing worker safety, and optimizing operational efficiency through systematic environmental navigation and human-robot collaboration across diverse industrial and hazardous work applications. Their innovative Guardian series represents the pinnacle of human-augmented robotics, providing standardized methodologies that support intelligent automation and collaborative robotics across complex industrial scenarios.

H3: Advanced Mobile Robotics Capabilities of Industrial AI Tools

The Sarcos Technology platform's AI tools offer extensive mobile robotics capabilities for comprehensive industrial automation and human capability enhancement:

Environmental Navigation and Perception Systems:

Advanced sensor fusion technology that enables robots to navigate complex unstructured environments safely

Real-time mapping capabilities that create detailed environmental models for optimal path planning

Obstacle detection and avoidance systems that ensure safe operation around human workers and equipment

Adaptive locomotion algorithms that enable robots to traverse various terrains and industrial surfaces

Environmental hazard recognition that identifies dangerous conditions and implements appropriate safety protocols

Dexterous Manipulation and Task Execution:

High-precision robotic arms with human-like dexterity for complex manipulation tasks

Advanced gripper systems that handle diverse objects with appropriate force and precision

Tool integration capabilities that enable robots to use standard industrial tools and equipment

Task learning algorithms that allow robots to adapt manipulation strategies based on environmental feedback

Quality control systems that ensure consistent task execution and operational reliability

Human-Robot Collaboration and Safety Integration:

Collaborative control systems that enable seamless human-robot teamwork in shared workspaces

Safety monitoring protocols that continuously assess worker proximity and operational risks

Intuitive interface systems that allow human operators to guide and supervise robotic operations

Emergency response capabilities that immediately halt operations when safety concerns arise

Communication systems that provide real-time status updates and operational coordination

H3: Machine Learning Integration of Industrial Robotics AI Tools

Sarcos Technology incorporates sophisticated machine learning algorithms specifically designed for industrial automation and human-robot collaboration across diverse operational environments and task requirements. The platform's AI tools utilize advanced adaptive learning and operational analytics that understand industrial processes while automatically optimizing task execution and safety enhancement requirements.

The system employs intelligent automation algorithms and collaborative robotics models that learn from operational experience to provide increasingly effective task execution while maintaining safety standards and operational efficiency across industrial robotics applications. These AI tools understand the complexity of modern industrial environments while providing automated solutions that enhance both operational effectiveness and worker safety outcomes.

H2: Operational Performance Analysis and Safety Impact of Industrial Robotics AI Tools

Comprehensive evaluation studies demonstrate the significant operational improvements and safety enhancements achieved through Sarcos Technology AI tools compared to traditional industrial automation approaches:

| Industrial Performance Metric | Traditional Automation | AI Tools Enhanced | Efficiency Gain | Safety Improvement | Cost Reduction | Flexibility Increase |

|---|---|---|---|---|---|---|

| Task Execution Speed | 100% baseline rate | 180% improved rate | 80% faster completion | Reduced human exposure | Labor cost savings | Adaptive operations |

| Operational Safety Score | 75% safety compliance | 98% safety compliance | 31% improvement | Zero injury incidents | Insurance savings | Risk mitigation |

| Environmental Adaptability | 20% flexibility rating | 85% flexibility rating | 325% improvement | Dynamic response | Reduced downtime | Versatile deployment |

| Human Worker Productivity | Baseline performance | 150% enhanced output | 50% improvement | Augmented capabilities | Efficiency gains | Collaborative benefits |

| Maintenance Requirements | Weekly service needs | Monthly service needs | 75% reduction | Predictive maintenance | Operational savings | Reliability improvement |

H2: Implementation Strategies for Industrial Robotics AI Tools Integration

Manufacturing companies and industrial operators worldwide implement Sarcos Technology AI tools for comprehensive automation enhancement and safety improvement initiatives. Heavy industry sectors utilize these frameworks for hazardous environment operations, while manufacturing facilities integrate collaborative robotics capabilities for productivity optimization and worker safety enhancement.

H3: Hazardous Environment Operations Through Robotics AI Tools

Industrial companies operating in dangerous environments leverage these AI tools to create sophisticated safety programs that systematically reduce human exposure to hazardous conditions while providing comprehensive automation capabilities for various high-risk operations and safety-critical task requirements. The technology enables safety managers to establish protective operational protocols while scaling automation capabilities to match growing safety requirements and operational complexity demands.

The platform's collaborative approach helps industrial operators establish comprehensive safety intelligence strategies while providing operational teams with transparency into risk reduction opportunities and automation optimization possibilities. This strategic approach supports industrial safety initiatives while ensuring effective operational practices that meet regulatory requirements and safety objectives across diverse hazardous environments and industrial applications.

H3: Manufacturing Productivity Enhancement Using Collaborative AI Tools

Manufacturing facilities and production companies utilize Sarcos Technology AI tools for comprehensive operational analytics that accelerates production efficiency while providing systematic automation and collaboration recommendations across diverse manufacturing processes and production requirements. The technology enables production managers to focus on strategic optimization rather than manual task execution, while ensuring that manufacturing strategies align with productivity objectives and quality standards.

Production teams can now develop more effective manufacturing strategies that leverage automated assistance while maintaining confidence in product quality and operational safety effectiveness. This management approach supports advanced manufacturing initiatives while providing operational foundations that enable systematic productivity optimization and quality enhancement with reliable automation characteristics across diverse industrial environments.

H2: Integration Protocols for Industrial Robotics AI Tools Implementation

Successful deployment of industrial robotics AI tools in manufacturing environments requires careful integration with existing production systems, safety protocols, and operational frameworks. Technology organizations must consider equipment compatibility, safety compliance, and workforce training requirements when implementing these advanced automation technologies.

Technical Integration Requirements:

Industrial control system connectivity for comprehensive automation coordination and operational workflow integration

Safety system compatibility for systematic risk management and emergency response protocol coordination

Production management system alignment for integrated operational tracking and performance optimization effectiveness

Network infrastructure enhancement for supporting reliable robotics communication and control system connectivity

Operational Implementation Considerations:

Workforce training programs for leveraging collaborative robotics and automation enhancement strategies

Safety protocol coordination education for understanding AI-enhanced operations and risk management processes

Production team collaboration training for optimizing human-robot interaction and operational effectiveness

Management system alignment for establishing automated workflow protocols and performance monitoring strategies

H2: Safety Standards and Regulatory Compliance in Industrial Robotics AI Tools

Sarcos Technology maintains strict safety standards and regulatory compliance protocols while providing comprehensive industrial automation that supports operational effectiveness and worker protection objectives. The platform's safety-first approach ensures that robotic operations meet industry safety requirements while providing manufacturing teams with enhanced capabilities that improve productivity without compromising worker safety or operational integrity.

The company balances automation capabilities with safety considerations to ensure that industrial robotics delivers effective operational value while maintaining regulatory compliance and safety excellence in complex manufacturing environments. This approach enables organizations to leverage advanced automation while accessing professional robotics solutions that meet industry safety requirements and regulatory compliance standards.

H2: Advanced Applications and Future Development of Industrial Robotics AI Tools

The industrial robotics technology landscape continues evolving as AI tools become more sophisticated and specialized for emerging manufacturing requirements. Future capabilities include autonomous maintenance operations, predictive equipment management, and advanced integration with artificial intelligence production optimization that further enhance operational effectiveness and safety enhancement across diverse industrial environments.

Sarcos Technology continues expanding their AI tools' capabilities to include additional industrial specializations, sector-specific applications, and integration with emerging technologies like Internet of Things manufacturing systems and automated quality control platforms. Future platform developments will incorporate advanced operational analytics techniques, enhanced safety controls, and comprehensive production intelligence capabilities for next-generation manufacturing workflows.

H3: Autonomous Maintenance Integration Opportunities for Robotics AI Tools

Technology leaders increasingly recognize opportunities to integrate industrial robotics AI tools with autonomous maintenance platforms and predictive equipment management systems that require systematic operational monitoring and maintenance optimization capabilities. The technology enables deployment of comprehensive maintenance intelligence that maintains operational reliability while supporting predictive maintenance strategies and equipment longevity applications.

The platform's integration capabilities support advanced maintenance strategies that consider autonomous operation requirements, predictive maintenance optimization needs, and operational efficiency when implementing comprehensive industrial management systems. This integrated approach enables more sophisticated manufacturing applications that balance automation effectiveness with maintenance capabilities and operational reliability standards across emerging industrial environments.

H2: Economic Impact and Strategic Value of Industrial Robotics AI Tools

Organizations implementing Sarcos Technology AI tools report substantial returns on investment through improved operational efficiency, enhanced worker safety, and reduced operational costs. The technology's ability to automate complex tasks while maintaining safety standards typically generates productivity improvements and cost savings that exceed platform investments through enhanced operational capabilities and reduced safety incidents.

Industrial analysis demonstrates that collaborative robotics typically improves operational efficiency by 150-250% while reducing safety incidents by 80-95%. These improvements translate to significant competitive advantages and operational savings that justify technology investments across diverse industrial projects and manufacturing initiatives while supporting long-term operational excellence and safety enhancement objectives.

Frequently Asked Questions (FAQ)

Q: How do AI tools help industrial companies enhance worker safety without replacing human employees or reducing workforce requirements?A: Industrial robotics AI tools like Sarcos Technology focus on human augmentation rather than replacement, using collaborative systems that enhance worker capabilities while removing humans from dangerous situations through intelligent automation support.

Q: Can AI tools effectively operate in unstructured industrial environments while maintaining operational safety and task execution quality?A: Advanced AI tools employ sophisticated environmental perception and adaptive navigation that systematically handle complex industrial conditions while providing reliable task execution through comprehensive safety monitoring and environmental awareness.

Q: What level of technical expertise do industrial robotics AI tools require for effective deployment and operational management?A: AI tools like Sarcos Technology provide intuitive interfaces and automated operation capabilities that enable industrial teams to leverage advanced robotics while maintaining operational control through user-friendly management systems.

Q: How do AI tools ensure consistent task execution while adapting to changing industrial conditions and operational requirements?A: Modern AI tools utilize machine learning algorithms and adaptive control systems that provide reliable performance through systematic learning from operational experience and environmental feedback for consistent quality outcomes.

Q: What safety considerations should industrial companies evaluate when implementing collaborative robotics AI tools?A: AI tools typically include comprehensive safety monitoring, emergency response protocols, and regulatory compliance features that ensure worker protection through verified safety systems and industry-standard operational protocols.