Agricultural producers across America face an unprecedented labor shortage that threatens the viability of specialty crop operations. Pecan growers particularly struggle during harvest seasons when finding sufficient workers becomes nearly impossible, leading to significant crop losses and reduced profitability. Traditional harvesting methods require large crews of seasonal workers who must carefully collect nuts by hand or operate mechanical shakers that often damage trees and reduce future yields. The timing of pecan harvests is critical, as nuts left on the ground too long deteriorate rapidly, while premature collection results in lower quality products.

Many family farms and commercial orchards have abandoned pecan production entirely due to labor costs that can exceed 60% of total operational expenses. The agricultural industry desperately needs innovative solutions that can maintain harvest quality while reducing dependence on seasonal labor. Advanced AI tools are emerging as transformative technologies that address these critical challenges, with Pecan Robotics leading this agricultural revolution through specialized autonomous harvesting systems designed specifically for nut crop operations.

H2: The Strategic Importance of AI Tools in Modern Agricultural Operations

Contemporary agriculture faces mounting pressure from labor shortages, rising operational costs, and increasing quality standards demanded by consumers and processors. Traditional farming methods cannot scale efficiently to meet production requirements while maintaining economic viability in competitive global markets.

Agricultural AI tools enable precision harvesting that surpasses human capabilities in consistency, timing, and quality control. These sophisticated systems operate continuously without fatigue, process complex environmental data in real-time, and make harvesting decisions based on optimal ripeness indicators that human workers might miss.

H2: Pecan Robotics' Specialized AI Tools for Autonomous Harvesting

Pecan Robotics has positioned itself as the premier developer of AI tools specifically engineered for nut crop harvesting operations. Their autonomous robotic systems combine advanced computer vision, machine learning algorithms, and precision mechanical engineering to deliver harvesting solutions that exceed traditional methods in both efficiency and quality.

H3: Computer Vision AI Tools for Precision Nut Detection

Pecan Robotics' platform employs sophisticated AI tools that analyze visual data to identify harvestable nuts with remarkable accuracy. The system's computer vision algorithms distinguish between ripe nuts, immature specimens, and debris while navigating complex orchard environments.

Vision System Capabilities:

Multi-spectral imaging for ripeness assessment

3D depth perception for accurate positioning

Real-time object classification and sorting

Weather condition adaptation algorithms

Tree branch and obstacle avoidance systems

The platform's AI tools process thousands of visual data points per second, enabling robots to make harvesting decisions faster and more accurately than human workers while maintaining gentle handling that preserves nut quality.

H3: Autonomous Navigation Through Agricultural AI Tools

Pecan Robotics' systems utilize advanced AI tools for autonomous navigation through diverse orchard terrains and varying tree configurations:

| Navigation Feature | Traditional Methods | Pecan Robotics AI Tools | Performance Improvement |

|---|---|---|---|

| Terrain Adaptation | Manual adjustment required | Automatic terrain mapping | 100% autonomous operation |

| Tree Row Navigation | Human guidance needed | AI-powered path planning | 95% accuracy in complex orchards |

| Obstacle Avoidance | Frequent stops/redirections | Real-time hazard detection | 85% reduction in navigation delays |

| Weather Adaptability | Operations suspended | Continuous condition monitoring | 40% extended operating window |

| Harvest Coverage | 60-80% collection rate | 90-95% collection rate | 15-35% improvement |

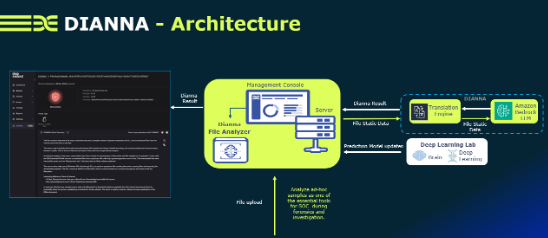

H2: Technical Architecture of Agricultural Harvesting AI Tools

Pecan Robotics' platform integrates multiple AI tools working in coordination to achieve optimal harvesting performance. The system combines sensor fusion, predictive analytics, and adaptive control algorithms to respond dynamically to changing orchard conditions.

The robots' AI tools continuously learn from harvesting experiences, improving performance over time through machine learning algorithms that adapt to specific orchard characteristics, seasonal variations, and crop quality parameters.

H3: Sensor Integration in Robotic AI Tools

Pecan Robotics' systems employ comprehensive sensor arrays that feed data to AI tools for decision-making:

Primary Sensor Technologies:

High-resolution cameras with macro lens capabilities

LiDAR systems for precise distance measurement

Ultrasonic sensors for close-proximity detection

Accelerometers and gyroscopes for stability control

Environmental sensors for weather monitoring

AI Processing Functions:

Real-time image analysis and pattern recognition

Predictive modeling for optimal harvest timing

Quality assessment algorithms for nut grading

Mechanical system optimization and control

Maintenance scheduling and performance monitoring

H2: Quality Control and Sorting Through AI Tools Implementation

Professional nut processing requires consistent quality standards that traditional harvesting methods struggle to maintain. Pecan Robotics' AI tools implement sophisticated quality control mechanisms that ensure harvested nuts meet commercial specifications while minimizing damage during collection.

H3: Automated Quality Assessment Using AI Tools

The platform's AI tools analyze multiple quality indicators simultaneously to grade nuts during the harvesting process:

Quality Assessment Parameters:

Shell integrity and surface condition evaluation

Size classification and uniformity measurement

Moisture content estimation through visual analysis

Defect detection including cracks and discoloration

Contamination identification and removal protocols

These AI tools generate detailed quality reports that help growers optimize their harvesting strategies and improve overall crop value through better post-harvest handling decisions.

H2: Operational Efficiency Gains from Agricultural AI Tools

Farms implementing Pecan Robotics' systems report substantial improvements in harvesting productivity and cost management:

Performance Improvements:

Harvesting speed increased by 200-300% compared to manual methods

Labor costs reduced by 50-70% during peak harvest periods

Nut quality consistency improved by 40-60%

Harvest window extended by 25-35% through weather adaptability

Overall operational costs decreased by 30-45%

H3: Case Studies Demonstrating AI Tools Impact in Agriculture

Commercial Pecan Operation Success:A 500-acre pecan orchard in Georgia deployed Pecan Robotics' AI tools to address chronic labor shortages. The autonomous system harvested 85% of the crop in half the time previously required by manual crews, while improving nut quality grades by 30% through consistent handling protocols.

Family Farm Implementation:A third-generation pecan farm in Texas used Pecan Robotics' AI tools to maintain operations when seasonal workers became unavailable. The system enabled the family to harvest their entire 150-acre orchard with minimal additional labor while achieving their highest-quality crop in over a decade.

H2: Advanced Features in Agricultural Robotics AI Tools

Pecan Robotics continues expanding system capabilities through ongoing research and development focused on emerging agricultural technology needs. Recent enhancements include predictive maintenance algorithms, multi-crop adaptation capabilities, and integration with farm management software systems.

H3: Predictive Maintenance Through AI Tools

The platform's AI tools monitor system performance continuously to predict maintenance needs before mechanical failures occur:

Maintenance Prediction Categories:

Component wear analysis and replacement scheduling

Performance degradation detection and optimization

Environmental impact assessment on system longevity

Operational efficiency monitoring and adjustment

Cost-benefit analysis for upgrade recommendations

These predictive capabilities minimize downtime during critical harvest periods while optimizing long-term system reliability and performance.

H2: Integration Ecosystem for Farm Management AI Tools

Pecan Robotics' platform connects with existing farm management systems through comprehensive data sharing protocols and software integrations. These AI tools work seamlessly with precision agriculture platforms, inventory management systems, and financial planning tools used throughout modern farming operations.

H3: Data Analytics and Reporting in Agricultural AI Tools

The system provides comprehensive analytics that help growers make informed decisions about their operations:

Analytics Capabilities:

Harvest yield predictions based on tree health monitoring

Quality trend analysis for market optimization

Cost per pound calculations for profitability assessment

Seasonal performance comparisons for planning improvements

Environmental impact reporting for sustainability compliance

Integration Features:

Farm management software connectivity

Financial planning system data export

Quality control database synchronization

Inventory tracking and logistics coordination

Regulatory reporting and compliance documentation

H2: Future Innovation in Agricultural AI Tools Development

Pecan Robotics' development roadmap focuses on expanding capabilities to serve broader agricultural markets while improving existing pecan harvesting performance. Upcoming features include multi-crop harvesting adaptability, enhanced weather resistance, and integration with autonomous transportation systems.

The platform's AI tools will soon incorporate advanced predictive analytics that forecast optimal harvesting schedules weeks in advance, enabling growers to plan operations more effectively and maximize crop value through precise timing decisions.

H3: Industry Transformation Through Next-Generation AI Tools

The agricultural industry anticipates significant changes as AI tools become more sophisticated and accessible to farms of all sizes:

Projected Agricultural Evolution:

Widespread adoption of autonomous harvesting systems

Reduced dependence on seasonal labor markets

Improved crop quality through consistent handling protocols

Enhanced profitability for specialty crop producers

Greater sustainability through precision resource utilization

Frequently Asked Questions (FAQ)

Q: How do agricultural AI tools handle different weather conditions during harvest?A: Pecan Robotics' AI tools include weather monitoring systems that adapt operations automatically, continuing to harvest safely in light rain or wind while pausing during severe conditions to protect both equipment and crop quality.

Q: Can these AI tools work effectively in orchards with varying tree sizes and configurations?A: Yes, the platform's AI tools use adaptive navigation algorithms that map individual orchard layouts and adjust harvesting patterns to accommodate different tree heights, spacing, and terrain variations.

Q: What training is required for farm operators to use these AI tools effectively?A: Pecan Robotics provides comprehensive training programs that typically require 2-3 days for basic operation, with ongoing support and advanced training modules available for optimizing system performance.

Q: How do AI tools ensure gentle handling that doesn't damage nuts during collection?A: The system's AI tools control robotic arms with precision sensors that adjust grip pressure and movement speed based on nut size and shell condition, resulting in significantly less damage than traditional mechanical harvesting methods.

Q: Can agricultural AI tools adapt to harvest other types of nuts besides pecans?A: While initially designed for pecans, Pecan Robotics' AI tools can be adapted for other tree nuts through software updates and mechanical modifications, with ongoing development for almonds, walnuts, and hazelnuts.