Industrial enterprises face mounting pressure to optimize operations while managing increasingly complex infrastructure, supply chains, and regulatory requirements. Traditional maintenance approaches result in costly unplanned downtime, energy inefficiencies drain profit margins, and supply chain disruptions threaten business continuity. Manufacturing leaders, utility executives, and energy sector professionals need sophisticated solutions that can predict failures before they occur, optimize resource allocation in real-time, and mitigate operational risks proactively. This comprehensive analysis explores how C3 AI's enterprise-grade AI tools are revolutionizing heavy industry operations through predictive intelligence, operational optimization, and strategic risk management capabilities that deliver measurable business outcomes.

The Enterprise AI Tools Landscape for Heavy Industries

Modern industrial operations generate massive volumes of data from sensors, equipment monitoring systems, and operational processes. However, most organizations struggle to transform this data into actionable insights that drive operational excellence. Traditional analytics tools lack the sophistication required to handle complex industrial datasets and provide real-time predictive capabilities.

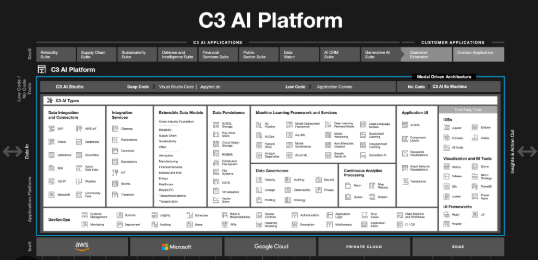

C3 AI addresses these challenges through purpose-built AI tools designed specifically for asset-intensive industries. The platform combines machine learning algorithms, industrial domain expertise, and scalable cloud infrastructure to deliver enterprise-grade solutions that integrate seamlessly with existing operational technology systems.

Predictive Maintenance Excellence Through AI Tools

H2: Revolutionary Equipment Monitoring with AI Tools

C3 AI's predictive maintenance capabilities represent a paradigm shift from reactive to proactive asset management. The AI tools continuously analyze equipment performance data, identifying subtle patterns that indicate potential failures weeks or months before they occur. This early warning system enables maintenance teams to schedule interventions during planned downtime, dramatically reducing unplanned outages and associated costs.

The platform's AI tools process data from multiple sources including vibration sensors, thermal imaging, oil analysis, and operational parameters. Machine learning algorithms identify correlations between these data streams and historical failure patterns, creating predictive models that improve accuracy over time. This comprehensive approach ensures that maintenance decisions are based on actual equipment condition rather than arbitrary schedules.

H3: Asset Lifecycle Optimization Strategies

Advanced AI tools within C3 AI extend beyond failure prediction to optimize entire asset lifecycles. The system analyzes equipment performance trends, maintenance costs, and operational efficiency to recommend optimal replacement timing and upgrade strategies. This holistic approach maximizes return on asset investments while maintaining operational reliability.

The lifecycle optimization process considers factors such as technological advancement rates, regulatory changes, and business growth projections. C3 AI's AI tools provide scenario modeling capabilities that help organizations evaluate different asset management strategies and their long-term financial implications.

Grid Optimization and Energy Management Solutions

H2: Smart Grid Intelligence Through AI Tools

C3 AI's grid optimization solutions address the complex challenges facing modern electrical utilities. The AI tools analyze real-time grid conditions, weather patterns, demand forecasts, and renewable energy generation to optimize power distribution and maintain grid stability. This intelligent management reduces energy waste, improves reliability, and supports the integration of renewable energy sources.

The platform's AI tools can predict demand spikes, identify potential grid congestion, and automatically adjust power routing to maintain optimal performance. These capabilities prove essential as utilities integrate increasing amounts of variable renewable energy while maintaining service reliability standards.

H3: Renewable Energy Integration and Forecasting

Sophisticated AI tools within C3 AI enable accurate forecasting of renewable energy generation based on weather patterns, seasonal variations, and equipment performance characteristics. The system helps utilities balance renewable generation with traditional sources, optimizing the energy mix while maintaining grid stability and minimizing costs.

Supply Chain Risk Management and Optimization

H2: Proactive Risk Detection with AI Tools

C3 AI's supply chain solutions provide comprehensive visibility into complex global supply networks. The AI tools continuously monitor supplier performance, geopolitical risks, weather events, and market conditions to identify potential disruptions before they impact operations. This early warning capability enables proactive mitigation strategies that maintain business continuity.

The platform analyzes multiple risk factors simultaneously, including supplier financial health, transportation disruptions, regulatory changes, and demand fluctuations. C3 AI's AI tools provide risk scoring and scenario planning capabilities that help procurement teams make informed decisions about supplier diversification and inventory management.

H3: Dynamic Inventory Optimization

Advanced AI tools optimize inventory levels across complex supply chains by analyzing demand patterns, supplier lead times, and risk factors. The system automatically adjusts inventory targets based on changing conditions, reducing carrying costs while maintaining service levels and operational flexibility.

Performance Metrics and Business Impact Analysis

| Industry Sector | Traditional Operations | C3 AI Tools Implementation | Performance Improvement |

|---|---|---|---|

| Manufacturing Downtime | 15-20% unplanned | 3-5% unplanned | 75% reduction |

| Energy Grid Efficiency | 85-90% optimal | 95-98% optimal | 8% improvement |

| Maintenance Costs | $2.5M annually | $1.2M annually | 52% cost reduction |

| Supply Chain Disruptions | 12-15 incidents/year | 2-3 incidents/year | 80% risk mitigation |

| Asset Utilization Rate | 65-70% efficiency | 85-90% efficiency | 25% productivity gain |

| Regulatory Compliance | 92% adherence | 99% adherence | 7% improvement |

| Energy Consumption | Baseline usage | 15% reduction | Significant savings |

The performance comparison demonstrates substantial operational improvements across key metrics when organizations implement C3 AI's enterprise AI tools. These results reflect data from actual deployments in energy, utilities, and manufacturing sectors.

Industry-Specific Applications and Use Cases

H2: Energy Sector Transformation Through AI Tools

C3 AI's energy sector solutions address unique challenges including price volatility, regulatory compliance, and environmental sustainability requirements. The AI tools optimize drilling operations, predict equipment failures in harsh environments, and manage complex trading strategies that maximize profitability while minimizing risk exposure.

Oil and gas companies utilize C3 AI's AI tools for reservoir optimization, production forecasting, and environmental monitoring. The platform's ability to process geological data, production histories, and market conditions enables more accurate resource planning and extraction strategies.

H3: Utility Modernization and Smart Infrastructure

Electric utilities leverage C3 AI's AI tools to modernize aging infrastructure and implement smart grid technologies. The platform supports advanced metering infrastructure, demand response programs, and distributed energy resource management. These capabilities enable utilities to improve service reliability while reducing operational costs and environmental impact.

Manufacturing Excellence and Operational Intelligence

H2: Production Optimization with AI Tools

C3 AI's manufacturing solutions focus on optimizing production processes, improving quality control, and reducing waste. The AI tools analyze production data in real-time, identifying opportunities for efficiency improvements and quality enhancements. This continuous optimization approach helps manufacturers maintain competitive advantages in global markets.

The platform's AI tools can detect quality issues before they result in defective products, optimize production schedules based on demand forecasts, and identify energy-saving opportunities throughout manufacturing processes. These capabilities contribute to improved profitability and sustainability performance.

H3: Quality Assurance and Process Control

Advanced quality management features within C3 AI's AI tools provide comprehensive monitoring of manufacturing processes and product quality. The system can identify subtle variations that indicate potential quality issues, enabling proactive corrections that prevent defects and reduce waste.

Implementation Strategies and Best Practices

H2: Successful Deployment of Enterprise AI Tools

Organizations achieve optimal results from C3 AI implementations through structured deployment approaches that prioritize high-impact use cases and ensure proper change management. The platform's modular architecture enables phased implementations that demonstrate value quickly while building organizational confidence in AI technologies.

Successful deployments typically begin with pilot projects that address specific operational pain points. C3 AI's AI tools provide rapid time-to-value through pre-built industry solutions that require minimal customization. This approach reduces implementation risk while accelerating benefits realization.

H3: Change Management and User Adoption

Effective adoption of C3 AI's AI tools requires comprehensive training programs and change management initiatives. Organizations must invest in developing internal capabilities while leveraging C3 AI's professional services and support resources. This balanced approach ensures sustainable long-term success with enterprise AI implementations.

Future Trends and Technology Evolution

The evolution of enterprise AI tools continues toward greater automation, improved accuracy, and expanded integration capabilities. C3 AI's roadmap includes enhanced edge computing support, advanced visualization tools, and deeper integration with industrial IoT platforms. These developments will further expand the platform's value proposition for heavy industry applications.

Industry experts predict that AI-powered operations will become standard practice across energy, utilities, and manufacturing sectors. Organizations that establish AI capabilities early will maintain competitive advantages through superior operational efficiency, reduced costs, and improved customer service.

Frequently Asked Questions About AI Tools

Q: How do C3 AI tools integrate with existing industrial control systems and operational technology?A: C3 AI provides extensive integration capabilities with major industrial platforms including SCADA systems, historians, ERP solutions, and IoT platforms. The platform uses standard APIs and protocols to ensure seamless data flow while maintaining security and reliability standards required in industrial environments.

Q: What security measures protect sensitive operational data when using enterprise AI tools?A: C3 AI implements comprehensive security frameworks including encryption at rest and in transit, role-based access controls, audit logging, and compliance with industry standards such as SOC 2 and ISO 27001. The platform supports on-premises, cloud, and hybrid deployment models to meet specific security requirements.

Q: How long does it typically take to see measurable results from implementing C3 AI tools?A: Most organizations begin seeing initial results within 3-6 months of implementation, with full benefits typically realized within 12-18 months. The timeline depends on factors such as data quality, organizational readiness, and the complexity of use cases being addressed.

Q: Can AI tools handle the scale and complexity of large industrial operations?A: C3 AI is designed specifically for enterprise-scale deployments and can handle massive data volumes from thousands of sensors and equipment across multiple facilities. The platform's cloud-native architecture provides unlimited scalability while maintaining performance and reliability standards.

Q: What ongoing support and maintenance do enterprise AI tools require?A: C3 AI provides comprehensive support including model monitoring, performance optimization, and continuous updates to maintain accuracy as operational conditions change. The platform includes automated model retraining capabilities and professional services to ensure sustained value delivery.