Imagine this: Tesla Optimus robot factory yield has soared to an incredible 92%. This is not just a number – it is a historic milestone for the entire robot manufacturing industry. Whether you are a tech enthusiast, a manufacturing professional, or someone who follows future trends, this breakthrough is worth your attention. The robot factory's high production capacity and impressive yield are redefining smart manufacturing standards and propelling global industry toward greater automation and efficiency. In this post, I will break down how Tesla's Optimus robot factory achieved such a high industrial yield, and reveal the technology and management secrets behind the scenes.

The Rise of the Optimus Robot Factory: From Vision to Reality

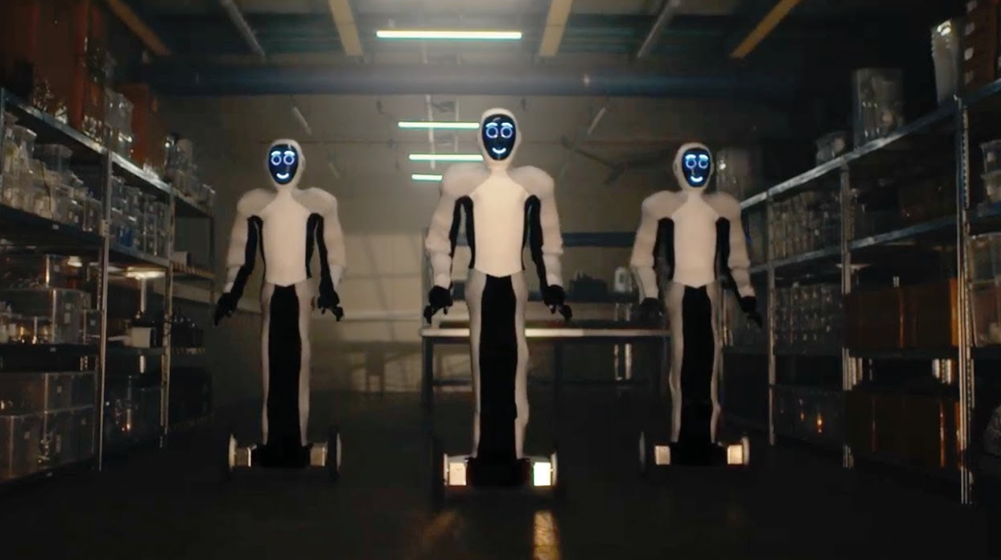

Since Tesla announced its own robot factory to produce Optimus humanoid robots, the entire manufacturing world has been watching to see if they could truly achieve mass production. At first, many doubted whether such complex robots could be assembled on a production line like cars. But Tesla proved the sceptics wrong – today, the Optimus robot factory's industrial yield is an astonishing 92%, leaving competitors speechless. Behind this figure is the relentless innovation and dedication of countless engineers and technical teams.What Is Industrial Yield? Why Is 92% So Impressive?

In manufacturing, industrial yield refers to the proportion of products that meet quality standards throughout the production process. For highly complex robots, with their multitude of parts and precise assembly requirements, even the smallest error can mean costly rework or scrapping. Traditionally, a yield of around 80% is considered excellent for a robot factory. The fact that the Tesla Optimus robot factory yield has reached 92% means that 92 out of every 100 robots are fully qualified, dramatically boosting efficiency and cost control. This achievement not only sets a new industry benchmark but also paves the way for large-scale deployment.

How Tesla Achieved a 92% Yield: Five Key Steps Explained

Want to know how the Tesla Optimus robot factory yield broke through? Here are five detailed steps that explain it all:1. Intelligent Design and Modular Production

Tesla considered modularity and standardisation from the very start of the Optimus robot design. Each key component can be independently tested and quickly swapped, greatly reducing assembly complexity and error rates. This allows every stage of the production line to flow efficiently, naturally raising the yield.2. Fully Automated Inspection Systems

The Optimus robot factory uses automated inspection technology at every step, from raw materials to finished products. AI vision and sensors rigorously check each detail. Any defect, however minor, is automatically sorted out and flagged for upstream correction, enforcing a 'zero-defect' policy. This smart detection speeds up production and drastically reduces human error.3. Data-Driven Real-Time Quality Tracking

Every Optimus robot generates massive amounts of data throughout its production – covering assembly, testing, and calibration. Tesla leverages big data analytics and cloud-based monitoring to instantly pinpoint sources of issues and continually optimise processes. This closed data loop lets management make real-time adjustments to keep yields rising.4. Efficient Human-Robot Collaboration

While the Optimus factory is highly automated, human engineers still play a vital role at key points. This synergy means complex problems are spotted and solved quickly. Engineers also fine-tune robot actions based on production data, creating an ongoing cycle of improvement.5. Continuous Innovation and Rapid Iteration

Tesla's R&D teams constantly refine both manufacturing processes and the robots themselves. For example, 3D printing enables one-piece construction of complex parts, reducing component counts. Software updates further improve assembly accuracy. This rapid iteration is a core reason why the Optimus factory maintains such a high yield.Optimus Robots vs Traditional Manufacturing Workers: Efficiency and Precision Compared

| Parameter | Optimus Bot v2.5 | Traditional Manufacturing Workers |

|---|---|---|

| Precision | ±0.01mm | ±0.1mm |

| Repeatability | 99.9% | 95% |

| Operating Hours | 24/7 | 8 - 10 hours per day |