Introduction: The Debate Over AI in Predictive Maintenance

In industries where equipment uptime is critical, predictive maintenance AI tools are touted as game-changers. They promise to foresee equipment failures, reduce downtime, and save costs by predicting when maintenance should occur before issues arise.

But here’s the controversial question: Are these AI tools truly preventing breakdowns and boosting efficiency, or are they overcomplicating straightforward maintenance tasks with unnecessary technology? In this article, we’ll explore some of the best AI tools for predictive maintenance, their features, and how they’re impacting various industries.

Why Predictive Maintenance Needs AI Tools

Managing equipment maintenance involves monitoring performance, predicting failures, and scheduling repairs. AI tools are designed to tackle these challenges by:

Enhancing accuracy: AI can analyze data from sensors to predict equipment failures with high precision.

Increasing efficiency: Automated systems optimize maintenance schedules and reduce unnecessary inspections.

Improving safety: AI tools help prevent catastrophic failures, ensuring a safer working environment.

But do these tools really deliver on their promises? Let’s dive into some of the top AI tools in predictive maintenance.

Top AI Tools for Predictive Maintenance

Here’s a breakdown of some of the most innovative AI tools currently transforming predictive maintenance:

1. IBM Maximo

Why it’s great: IBM Maximo leverages AI to provide a comprehensive asset management solution, focusing on predictive and preventive maintenance.

Key features:

AI-driven predictive analytics for identifying potential equipment failures

Automated insights for optimizing maintenance schedules and resource allocation

Integration with IBM’s cloud and IoT solutions for comprehensive data analysis

Pros:

Robust analytics capabilities with AI integration

Ideal for large enterprises needing detailed asset management solutions

Cons:

Requires technical expertise for setup and customization

Subscription costs may be high for smaller businesses

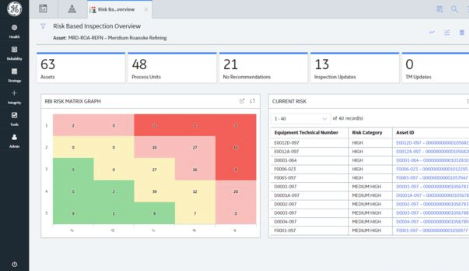

2. GE Predix Asset Performance Management (APM)

Why it’s great: GE Predix APM uses AI to offer a scalable platform for asset performance management, focusing on predictive analytics and risk management.

Key features:

AI-driven predictive analytics for asset health monitoring and failure prediction

Automated insights for enhancing risk management and maintenance planning

Integration with GE’s industrial IoT platform for real-time data processing

Pros:

Comprehensive asset monitoring capabilities with AI integration

Ideal for industries with critical asset performance needs

Cons:

Complex implementation process

Subscription costs could be prohibitive for smaller companies

3. Siemens MindSphere

Why it’s great: Siemens MindSphere uses AI to provide an open IoT operating system, focusing on predictive maintenance and data analytics.

Key features:

AI-driven predictive maintenance and data analytics for equipment monitoring

Real-time insights for improving maintenance efficiency and reducing downtime

Integration with Siemens’ suite of industrial applications

Pros:

High-level data integration capabilities with AI integration

Ideal for manufacturers seeking to optimize equipment performance

Cons:

Requires familiarity with Siemens’ IoT ecosystem

Subscription costs may be high for extensive usage

4. PTC ThingWorx

Why it’s great: PTC ThingWorx leverages AI to offer an industrial IoT platform, focusing on predictive maintenance and operational efficiency.

Key features:

AI-driven predictive maintenance and operational insights

Automated insights for enhancing equipment reliability and performance

Integration with PTC’s suite of IoT and augmented reality solutions

Pros:

Intuitive interface with AI integration for ease of use

Ideal for industries needing agile and responsive maintenance solutions

Cons:

Limited advanced features compared to larger platforms

Subscription required for full feature access

5. SAP Predictive Maintenance and Service

Why it’s great: SAP’s solution uses AI to provide a comprehensive platform for predictive maintenance, focusing on asset health and service management.

Key features:

AI-driven asset health monitoring and predictive analytics

Real-time insights for optimizing maintenance strategies and reducing costs

Integration with SAP’s suite of enterprise management solutions

Pros:

Comprehensive features with AI integration for various business needs

Ideal for enterprises seeking to enhance asset management

Cons:

Requires time to fully utilize all features

Subscription costs could increase with additional users and features

The Pros and Cons of AI Tools in Predictive Maintenance

While these tools offer significant advantages, they’re not without their challenges. Let’s break it down:

Pros:

Enhanced accuracy: AI tools predict equipment failures with high precision.

Increased efficiency: Automation optimizes maintenance schedules and reduces downtime.

Improved safety: Predictive maintenance prevents catastrophic failures, ensuring safety.

Cons:

High costs: Many AI tools are expensive, making them inaccessible to smaller businesses.

Complex implementation: Integrating AI tools into existing workflows can be challenging.

Dependence on technology: Over-reliance on AI may reduce human oversight and intuition.

FAQs About AI Tools in Predictive Maintenance

Q: Can AI tools replace traditional maintenance methods?

A: While AI tools enhance efficiency and accuracy, traditional methods are still essential for comprehensive equipment maintenance.

Q: Are these tools suitable for all types of industries?

A: Yes, many tools like IBM Maximo and Siemens MindSphere offer scalable features suitable for various industrial applications.

Q: Do AI tools guarantee improved maintenance outcomes?

A: AI tools significantly enhance the chances of improved outcomes through precise analytics and automation, but success also depends on strategic implementation and user engagement.

Conclusion: Are AI Tools the Future of Predictive Maintenance?

AI tools like IBM Maximo, GE Predix APM, Siemens MindSphere, PTC ThingWorx, and SAP Predictive Maintenance and Service are undeniably transforming predictive maintenance. They offer enhanced accuracy, increased efficiency, and improved safety, making it easier to avoid equipment failures.